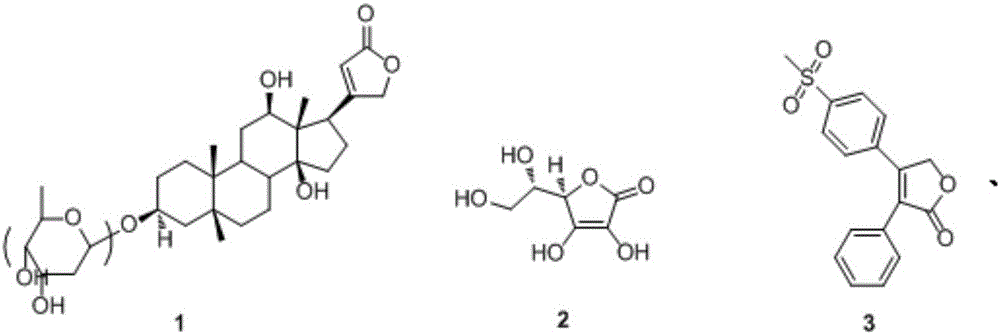

Method of preparing r-butenolide from alkenyl epoxide

A technology of butenolide and oxygen compound, applied in the direction of organic chemistry, etc., can solve the problem of few r-butenolide methods, and achieve the effects of condition optimization, high atom utilization rate, and low environmental hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

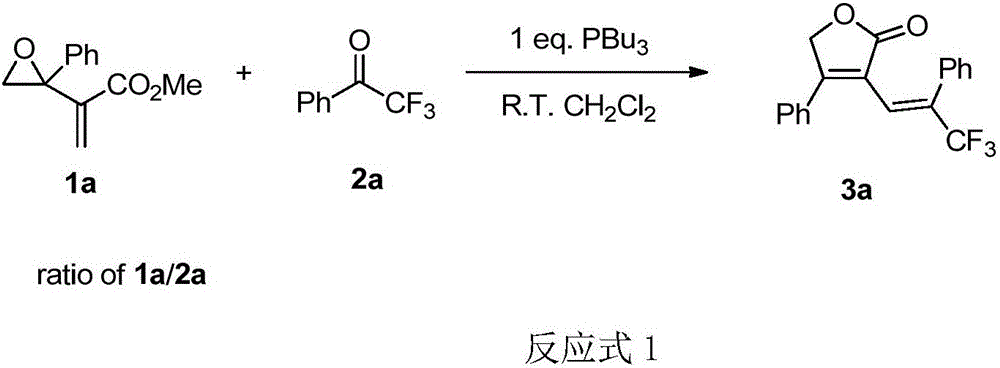

Embodiment 1

[0032] Add 0.5mL of dichloromethane to the reaction flask, then add 10.2mg (0.05mmol) of alkenyl epoxy compound, 17.4mg (0.1mmol) of trifluoroacetophenone, stir for a few minutes, and then add 12.4 ul (0.05 mmol) of tributylphosphine, stirred vigorously at room temperature, monitored by TLC, after the reaction was completed, separated the product by thin layer chromatography (petroleum ether: ethyl acetate = 6:1), and obtained 14.5 mg of the corresponding product , and the yield was 88%.

Embodiment 2

[0034] Add 0.5mL of dichloromethane to the reaction flask, then add 10.2mg (0.05mmol) of alkenyl epoxy compound, 10.1ul (0.1mmol) of benzaldehyde, stir for a few minutes, then add 12.4ul (0.05 mmol) of tributylphosphine, vigorously stirred at room temperature, monitored by TLC, after the reaction was completed, the product was separated by thin-layer chromatography (petroleum ether: ethyl acetate=6:1), and 8.0 mg of the corresponding product was obtained. was 61%.

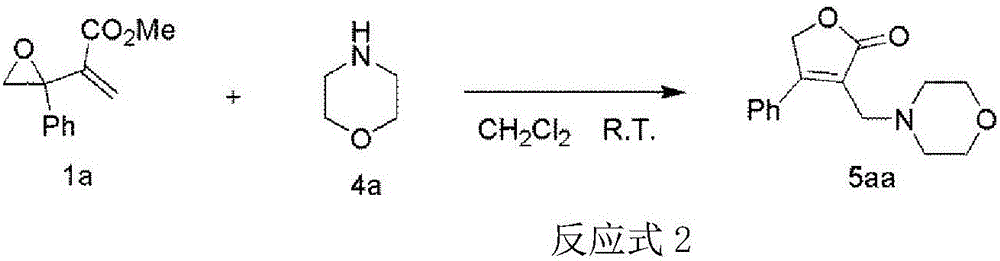

Embodiment 3

[0036] Add 0.5mL of dichloromethane to the reaction flask, then add 10.2mg (0.05mmol) of alkenyl epoxy compound, 8.7ul (0.1mmol) of morpholine, 6.9ul (0.05mmol) of triethylamine, at room temperature Vigorously stirred and monitored by TLC. After the reaction was completed, the product was separated by thin layer chromatography (petroleum ether: ethyl acetate = 4:1) to obtain 11.5 mg of the corresponding product with a yield of 89%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com