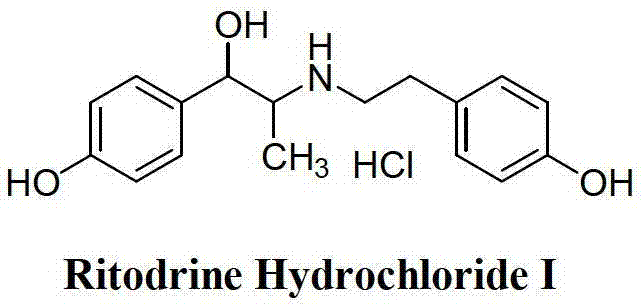

Preparation method of ritodrine hydrochloride

A technology for ritodrine hydrochloride and propanol hydrochloride, which is applied in the field of preparation of ritodrine hydrochloride to achieve the effects of high chemical selectivity, improved quality and control of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

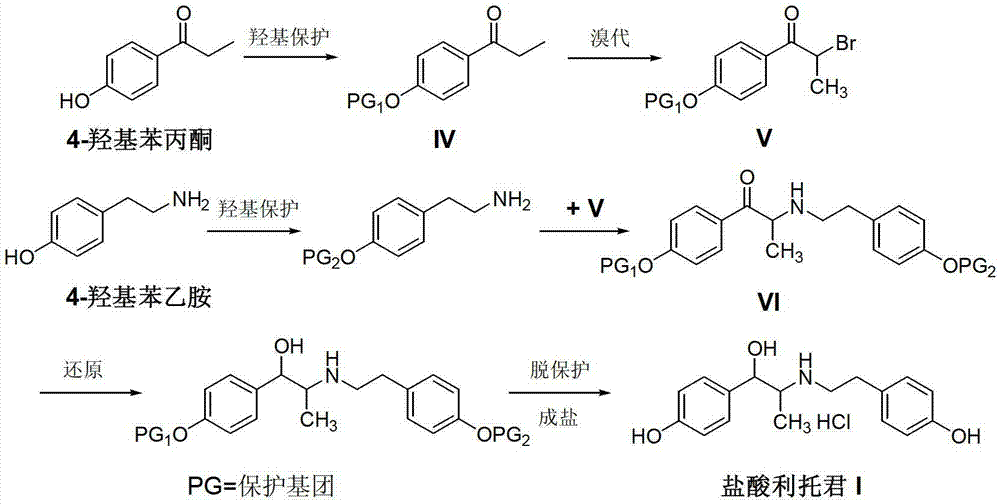

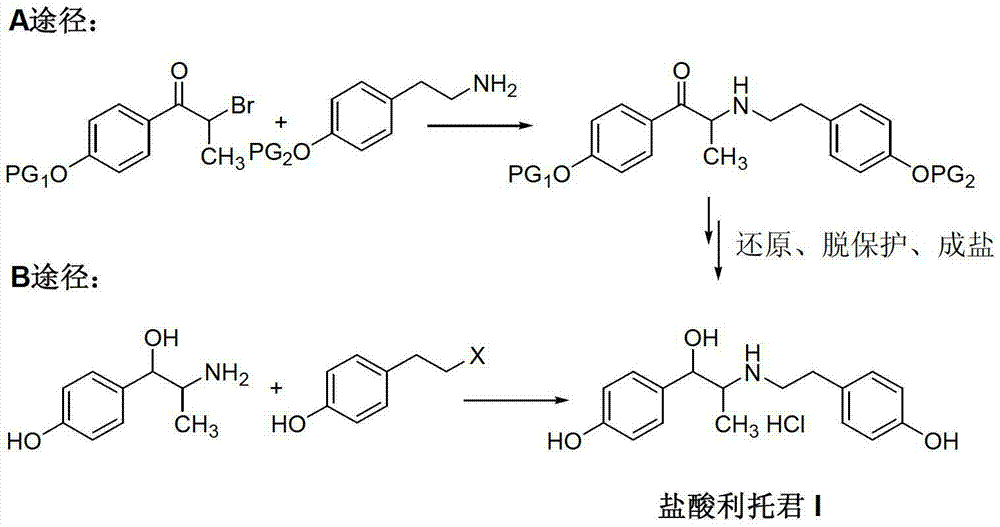

Method used

Image

Examples

Embodiment 1

[0026] Add 2-amino-1-(4-hydroxyphenyl)propanol hydrochloride (II) (50.2g, 0.25mol), triethylamine (25.0g, 0.25mol), potassium iodide (0.5 g, 1%eq) and absolute ethanol 125mL, warming up to 50-55°C, stirring until the system dissolves uniformly. 4-(2-Chloroethanol)phenol (III) (46.8 g, 0.3 mol) was slowly added dropwise to the reaction liquid, and the drop was completed in about 1 hour. Be warming up to 85 DEG C, continue to react for 6 hours, TLC detects that the reaction ends. Cool down to room temperature and remove triethylamine hydrochloride by filtration. The filtrate was adjusted to pH 4-5 with hydrochloric acid. Ethanol was recovered under reduced pressure, and the residue was recrystallized from a mixed solvent of n-hexane and ethyl acetate to obtain 66.8 g of ritodrine hydrochloride (I) as a white solid with a yield of 83.0%.

Embodiment 2

[0028] Add 2-amino-1-(4-hydroxyphenyl)propanol hydrochloride (II) (50.2g, 0.25mol), triethylamine (25.0g, 0.25mol), potassium iodide (0.5 g, 1%eq) and absolute ethanol 125mL, warming up to 50-55°C, stirring until the system dissolves uniformly. 4-(2-Chloroethanol)phenol (III) (60.0 g, 0.3 mol) was slowly added dropwise to the reaction solution, and the drop was completed in about 1 hour. Be warming up to 80 DEG C, continue to react for 3 hours, TLC detects that the reaction ends. Cool down to room temperature, and remove triethylamine hydrobromide by filtration. The filtrate was adjusted to pH 4-5 with hydrochloric acid. Ethanol was recovered under reduced pressure, and the residue was recrystallized from a mixed solvent of n-hexane and ethyl acetate to obtain 70.2 g of ritodrine hydrochloride (I) as a white solid with a yield of 87.2%.

Embodiment 3

[0030] Add 2-amino-1-(4-hydroxyphenyl)propanol hydrochloride (II) (50.2g, 0.25mol), potassium carbonate (17.5g, 0.13mol), potassium iodide (0.5g , 1%eq) and tetrahydrofuran 125mL, the temperature was raised to 40-50°C, and stirred until the system was dissolved uniformly. 4-(2-Chloroethanol)phenol (III) (46.8 g, 0.3 mol) was slowly added dropwise to the reaction liquid, and the drop was completed in about 1 hour. The temperature was raised to reflux, and the reaction was continued for 5 hours, and the reaction was detected by TLC. Cool down to room temperature, and remove insoluble matter by filtration. The filtrate was adjusted to pH 4-5 with hydrochloric acid. Tetrahydrofuran was recovered under reduced pressure, and the residue was recrystallized from a mixed solvent of n-hexane and ethyl acetate to obtain 64.5 g of ritodrine hydrochloride (I) as a white solid with a yield of 80.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com