Silicone rubber/unsaturated carbon chain rubber compatilizer based on hydrosilylation and preparing method and application thereof

A hydrosilylation reaction and unsaturated technology, which is applied in the field of rubber additives, can solve the problems of sacrificial system damping, high hardness of blended rubber, compatibilizer consumption, etc., and achieve good compatibilization effect, low raw material cost, and improved Effect of Tensile Strength and Tear Strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] (1) Preparation of hydrogen-containing silicone oil

[0059] 30g D 4 , 48g D 4 H Put into the polymerization reactor for dehydration, the dehydration conditions are -0.01~-0.02MPa, 40~80°C, 2h, dry nitrogen and ventilate, then raise the temperature to the polymerization temperature of 80~120°C, add hexamethyldisiloxane end-capping agent, Potassium hydroxide catalyst, normal pressure reaction for 24 hours, after the polymerization, the temperature was raised to 150°C, and the small molecule low boiling substances in the material were removed at 133-1330Pa, and the time was 4 hours to obtain hydrogen-containing silicone oil, the molecular weight of which was determined by hexamethyl di The amount of siloxane end-capping agent and potassium hydroxide catalyst is controlled, the number average molecular weight is about 7000, and the molar content of Si-H is about 66%.

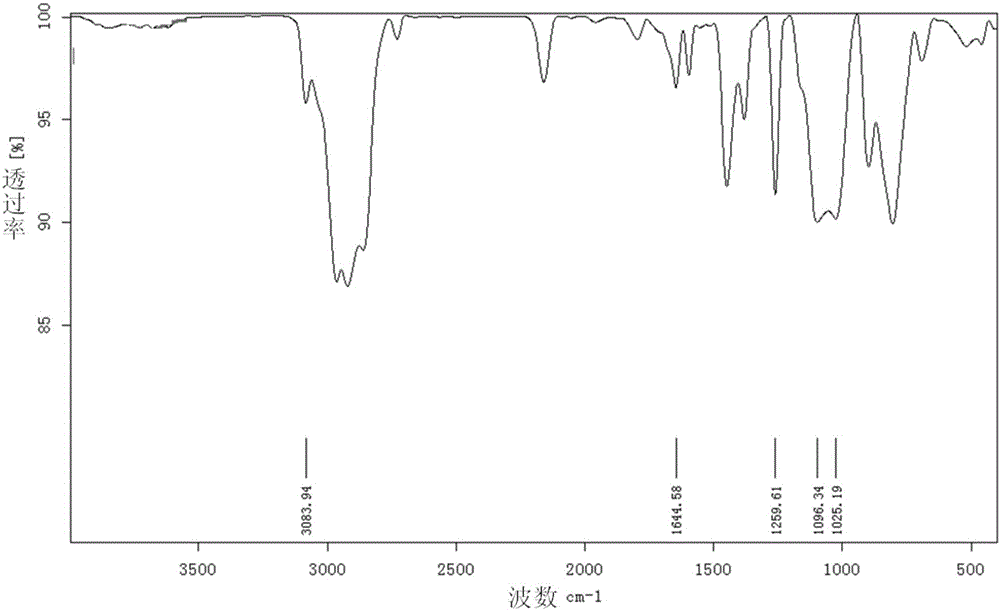

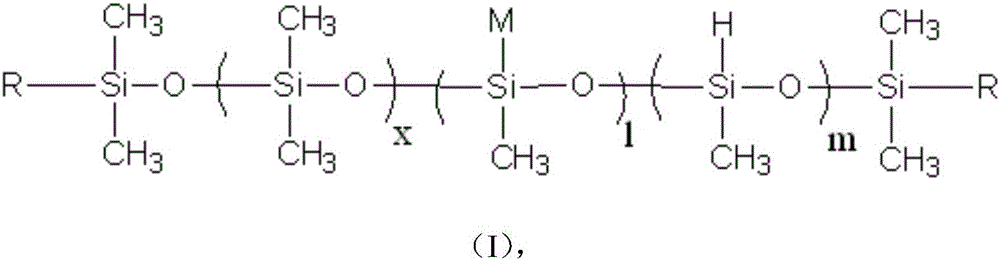

[0060] The structural formula of the obtained hydrogen-containing silicone oil is as follows:

[0061...

Embodiment 2

[0070] (1) Preparation of hydrogen-containing silicone oil

[0071] 30g D 4 , 48g D 4 H Put into the polymerization reactor for dehydration, the dehydration conditions are -0.01~-0.02MPa, 40~80°C, 2h, dry nitrogen and ventilate, then raise the temperature to the polymerization temperature of 80~120°C, add hexamethyldisiloxane end-capping agent, Tetramethylammonium hydroxide catalyst, reaction at normal pressure for 24 hours, after polymerization, raise the temperature to 150°C, and remove small molecular low boiling substances in the material at 133-1330Pa, and the time is 4 hours to obtain hydrogen-containing silicone oil, whose molecular weight passes six The amount of methyldisiloxane end-capping agent and tetramethylammonium hydroxide catalyst is controlled, the number average molecular weight is about 5000, and the Si-H molar content is about 66%.

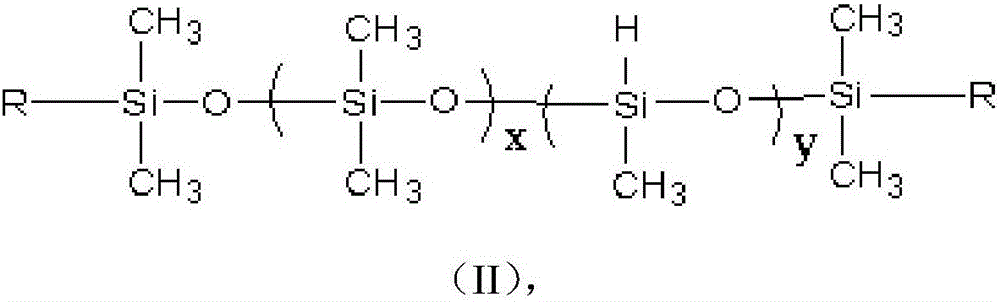

[0072] The structural formula of the obtained hydrogen-containing silicone oil is as follows:

[0073]

[0074] (2) P...

Embodiment 3

[0082] (1) Preparation of hydrogen-containing silicone oil

[0083] 30g D 4 , 24g D 4 H Put into the polymerization reactor for dehydration, the dehydration conditions are -0.01~-0.02MPa, 40~80°C, 2h, dry nitrogen and ventilate, then raise the temperature to the polymerization temperature of 80~120°C, add hexamethyldisiloxane end-capping agent, Concentrated sulfuric acid catalyst, react at normal pressure for 24 hours, after the polymerization, raise the temperature to 150°C, remove small molecular low boiling substances in the material at 133-1330Pa, and get hydrogen-containing silicone oil for 4 hours, the molecular weight of which is passed by hexamethyldisilica The amount of oxane end-capping agent and concentrated sulfuric acid catalyst is controlled, the number average molecular weight is about 5000, and the Si-H molar content is about 50%.

[0084] The structural formula of the obtained hydrogen-containing silicone oil is as follows:

[0085]

[0086] (2) Prepara...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com