A kind of cleaning antifouling type amphiphilic copolymer network and preparation method thereof

An amphiphilic copolymer, anti-fouling technology, applied in the direction of pharmaceutical formulations, medical preparations of non-active ingredients, prostheses, etc., can solve the problem of reducing the mechanical properties of the network, achieve chemical modification methods clean, good swelling performance , causing a variety of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] A clean antifouling type amphiphilic copolymer network, the preparation method of which is:

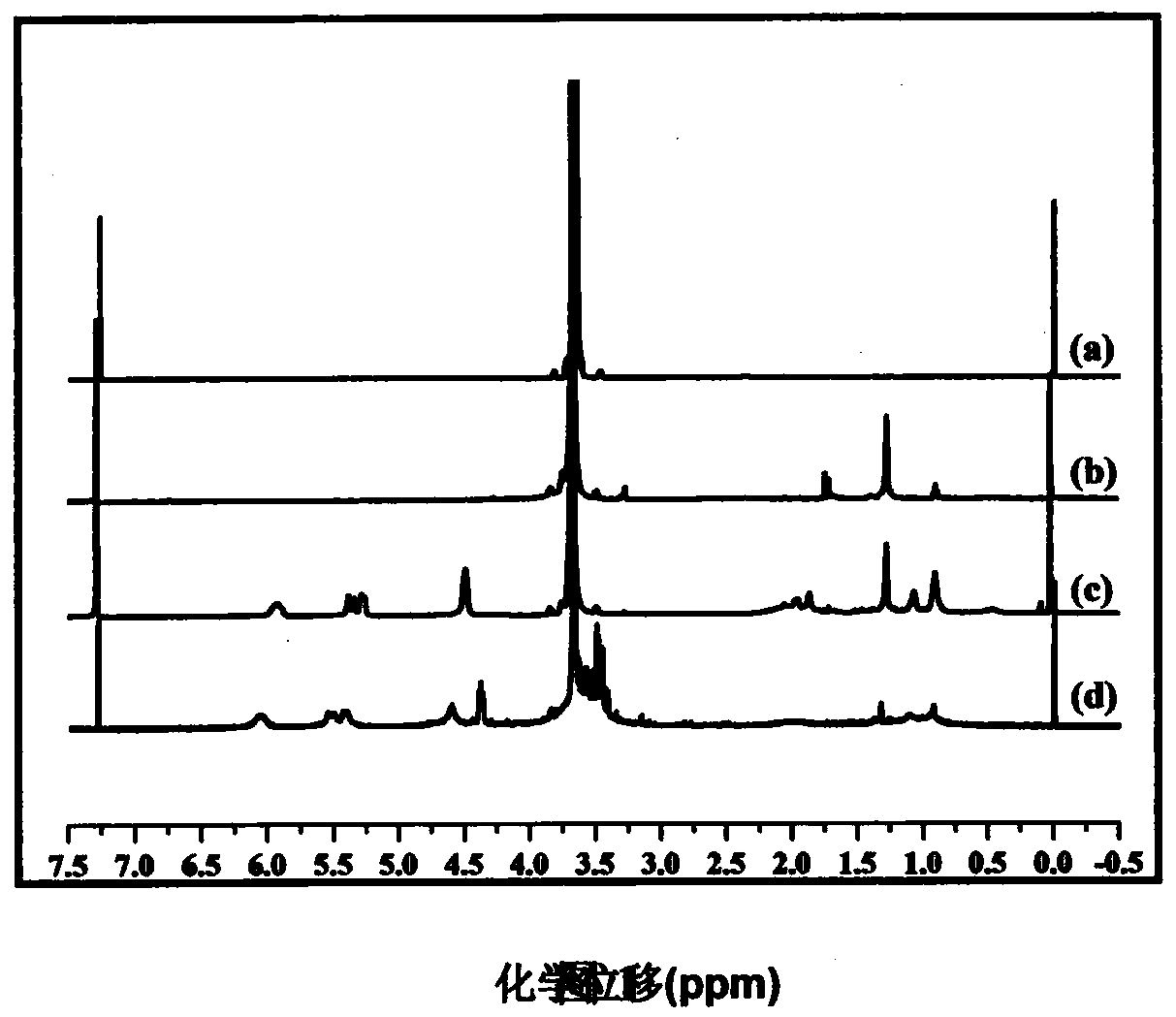

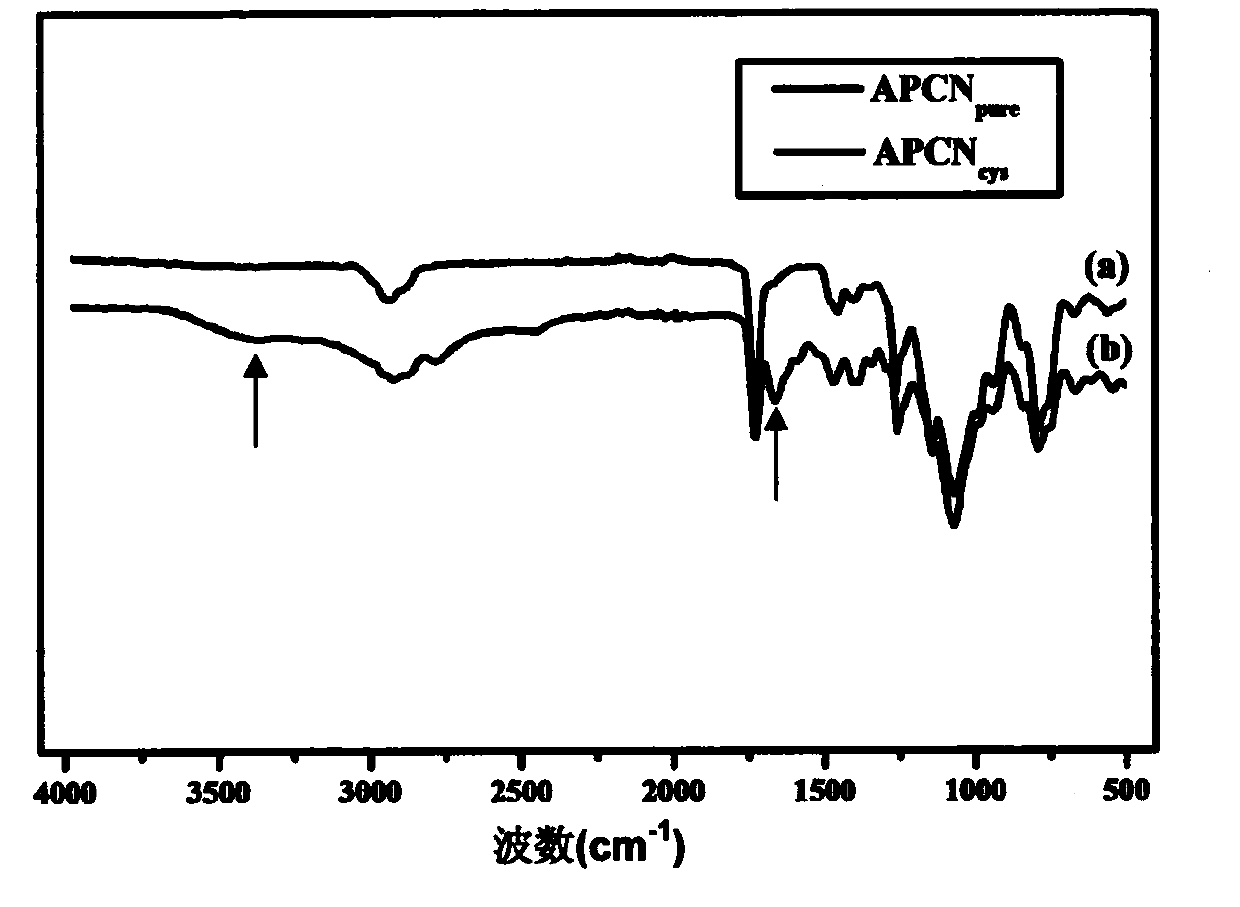

[0068] The first step: 3.2wt% RAFT reagent [2-(dodecyl trithiocarbonate group)-2-methylpropionic acid], 0.3wt% DMAP (4-dimethylaminopyridine), 2.6 wt% of DCC (N, N'-dicyclohexylcarbodiimide), 5.8wt% of PEG (polyethylene glycol, Mw=2k) and 88.1wt% of anhydrous dichloromethane were mixed, and put into four Fluorine stirring magnet, at room temperature (25 ° C) magnetic stirring reaction for 48 hours, the mixture was passed through a neutral alumina chromatography column (eluent is dichloromethane), the obtained filtrate was concentrated by rotary evaporation in vacuo, and washed with 10 Extract, wash and purify with ice n-hexane at 0°C, which is twice the amount of the product, and re-dissolve with dichloromethane after cold suction filtration. After several times of extraction and dissolution, the product was dried in a vacuum oven at 60°C to constant weight to obtain a light y...

Embodiment 2

[0075] A clean antifouling type amphiphilic copolymer network, the preparation method of which is:

[0076] The first step: utilize polyethylene glycol to prepare hydrophilic macromolecular chain transfer agent: 3.2wt% RAFT reagent [2-(dodecyl trithiocarbonate group)-2-methyl propionic acid], 0.4wt% of DMAP (4-dimethylaminopyridine), 2.6wt% of DCC (N, N'-dicyclohexylcarbodiimide), 5.8wt% of PEG (polyethylene glycol, Mw=4k) and The anhydrous dichloromethane of 88wt% is mixed, and put into tetrafluoro stirring magnet, at room temperature (25 ℃) after magnetic stirring reaction 48 hours, make mixture pass through neutral alumina chromatography column (eluent is dichloro Methane), the obtained filtrate was concentrated by rotary evaporation in vacuum, and extracted, washed and purified with 0°C ice n-hexane 10 times the amount of the product, and re-dissolved with dichloromethane after cold suction filtration. After several times of extraction and dissolution, the product was dri...

Embodiment 3

[0088] A clean antifouling type amphiphilic copolymer network, the preparation method of which is:

[0089] The first step: 3.2wt% RAFT reagent [2-(dodecyl trithiocarbonate group)-2-methylpropionic acid], 0.4wt% DMAP (4-dimethylaminopyridine), 3.3 wt% of DCC (N, N'-dicyclohexylcarbodiimide), 11.2wt% of PEG (polyethylene glycol, Mw=6k) and 81.9wt% of anhydrous dichloromethane were mixed, and put into four Fluorine stirring magnet, at room temperature (25 ° C) magnetic stirring reaction for 48 hours, the mixture was passed through a neutral alumina chromatography column (eluent is dichloromethane), the obtained filtrate was concentrated by rotary evaporation in vacuo, and washed with 10 Extract, wash and purify with ice n-hexane at 0°C that is twice the amount of the product, and re-dissolve with dichloromethane after cold suction filtration. After several times of extraction and dissolution, the product was dried in a vacuum oven at 60°C to constant weight to obtain a light ye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com