Paper-based degradable nutrition bowl and preparation method

A nutrient bowl and paper-based technology, applied in botany equipment and methods, culture medium, planting substrate, etc., can solve the problems of complex nutrient bowl preparation, waste environmental pollution, high cost of raw materials, etc., and achieve easy industrial production and large-scale The effects of popularization and application, increasing straw plasticity and shortening processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Crush the rice straw to 60 mesh and set aside; mix 10kg of paper and 190kg of water, the pulp concentration is 5%, stir for 10min at room temperature, the speed is 40 / min, and then stand for 60min; add 1.1g of rice straw powder, no binder , stirred at room temperature for 5 minutes, and the rotation speed was 40 / min; the raw material slurry was sucked into a pulp molding machine and pressed into shape; demolded and naturally dried for 2 days, the paper-based degradable nutritional bowl was obtained.

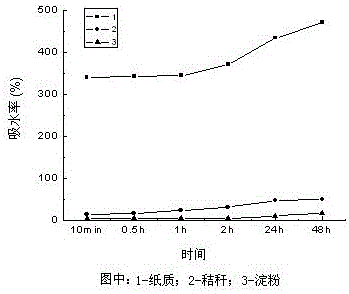

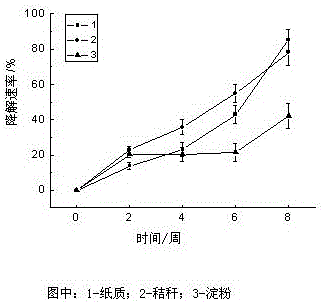

[0041] After testing, the paper-based degradable nutrition bowl has a tensile strength of 2.856MPa, an elongation at break of 4.176%, a water absorption rate of 280%, and a degradation rate of 100% within 126 days.

Embodiment 2

[0043] Crush the corn stalks to 70 mesh and set aside; mix 8 kg of paper and 135 kg of water, the pulp concentration is 5.6%, stir for 10 minutes at room temperature, rotate at a speed of 50 r / min, then let stand for 65 minutes; add 2.1 kg of corn stalk powder, 0.01 kg of starch, Stir at room temperature for 6 minutes at a speed of 50 r / min; suck the raw material slurry into a pulp molding machine and press it into a molding machine; remove the mold and place it in a blast oven, and dry it at 20°C for 180 minutes to obtain a paper-based degradable nutritional bowl.

[0044] After testing, the paper-based degradable nutrition bowl has a tensile strength of 5.863 MPa, an elongation at break of 3.225%, a water absorption rate of 285%, and a degradation rate of 100% in 119 days.

Embodiment 3

[0046] Crush the corn stalks to 80 mesh and set aside; mix 12kg of paper and 181kg of water, the pulp concentration is 6.2%, stir for 12min at room temperature, the speed is 50r / min, and then stand for 70min; add 5.2kg of corn stalk powder, 0.03kg of gelatin, Stir at room temperature for 6 minutes at a speed of 50 r / min; suck the raw material slurry into a pulp molding machine and press it into a molding machine; demold it and place it in a blast oven, and dry it at 30°C for 160 minutes to obtain a paper-based degradable nutritional bowl.

[0047] After testing, the paper-based degradable nutrition bowl has a tensile strength of 7.303 MPa, an elongation at break of 5.083%, a water absorption rate of 310%, and a degradation rate of 100% within 98 days.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com