A kind of method for the production of liprestatin by multi-stage fermentation

A multi-stage, liposic technology, applied in the field of fermentation engineering, can solve the problems of long fermentation period, low yield, complicated extraction and separation steps, etc., and achieve the effects of low cost, high titer, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

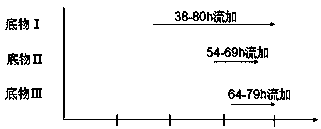

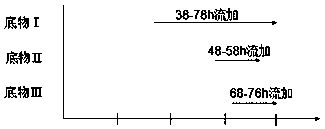

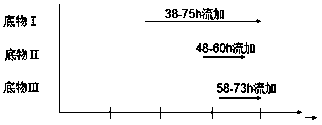

Image

Examples

Embodiment 1

[0026] ①Cultivation of seeds

[0027] The slant activation culture is to inoculate sandy soil spores on PDA slant medium (200g of potatoes, 20g of glucose, 20g of agar, 1000mL of water, natural pH), and cultivate them in an incubator at a temperature of 24°C for 7 days to obtain spores. .

[0028] Wash the slant of Stretomyces toxytricini NRRL 15443 spores with 10 mL of sterile saline, inoculate 2 mL into a 500 mL Erlenmeyer flask containing seed medium (filling volume 75 mL), at a temperature of 27 °C and a pH of 8.0, Cultivate for 24 h in a shaker with a rotating speed of 200 rpm to obtain a fermented seed culture medium; the composition of the fermented seed medium is (g / L): corn starch 3.5, fish peptone 5.0, yeast extract 3.0, NaCl 2.0, glucose 5.0, pressed soybean oil 3.0, K 2 HPO 4 1.5, pH 7.2.

[0029] ② Preparation before inoculation

[0030] Clean the fermenter with a volume of 5L, sterilize the empty tank with high pressure steam at 121°C for 20 minutes, cool t...

Embodiment 2

[0044] 1. Seed cultivation

[0045] The slant activation culture is to inoculate the sand spores on the PDA slant medium, and cultivate them in an incubator at a temperature of 26°C for 7 days to obtain the spore slant.

[0046] Wash the slant surface of Stretomyces toxytricini NRRL 15443 spores with 10 mL of sterile saline, inoculate 2 mL into a 500 mL Erlenmeyer flask containing seed medium (filling volume: 50 mL), at a temperature of 26°C and a pH of 8.5, Cultivate for 30 h in a shaker with a rotating speed of 200 rpm to obtain a fermented seed culture medium; the composition of the fermented seed medium is (g / L): corn starch 4.5, fish peptone 4.5, yeast extract 4.0, NaCl 3.0, glucose 4.5, pressed soybean oil 5.0, K 2 HPO 4 2.5, pH 7.2.

[0047] 2. Preparation before inoculation

[0048] Clean the fermenter with a volume of 5L, sterilize the empty tank with high pressure steam at 121°C for 20 minutes, cool to room temperature, assemble the thermometer, pH meter (correc...

Embodiment 3

[0061] 1. Seed cultivation

[0062] The slant activation culture is to inoculate the sand spores on the PDA slant medium, and cultivate them in an incubator at a temperature of 27°C for 6 days to obtain the spore slant.

[0063] Wash the slant surface of Stretomyces toxytricini NRRL 15443 spores with 10 mL of sterile saline, inoculate 2 mL into a 500 mL Erlenmeyer flask containing seed medium (filling volume 75 mL), at a temperature of 24 °C and a pH of 6.5, Cultivate for 48 h in a shaker with a rotating speed of 150 rpm to obtain a fermented seed culture medium; the composition of the fermented seed medium is (g / L): corn starch 5.0, fish peptone 3.0, yeast extract 1.0, NaCl 1.5, glucose 2.0, pressed soybean oil 3.5, K 2 HPO 4 3.0, pH 7.0.

[0064] 2. Preparation before inoculation

[0065] Clean the fermenter with a volume of 5L, sterilize the empty tank with high pressure steam at 121°C for 20 minutes, cool to room temperature, assemble the thermometer, pH meter (correc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com