Hydrogen-energy mixed gas production equipment and method

A technology for mixing gas and production equipment, applied in the direction of fuel, gas fuel, climate sustainability, etc., can solve the problems of reduced hydrogen and oxygen electrolysis efficiency, poor stability, large calorific value, etc., to improve heat transfer efficiency, control Convenience and the effect of reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Assembly of hydrogen energy mixed gas production equipment:

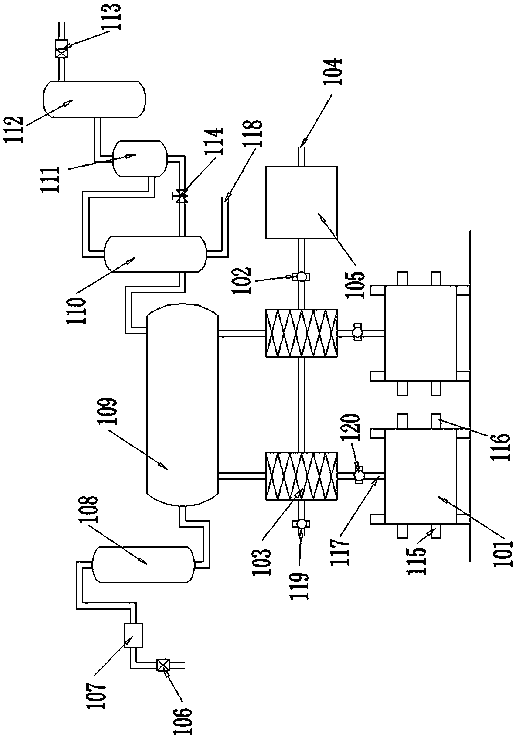

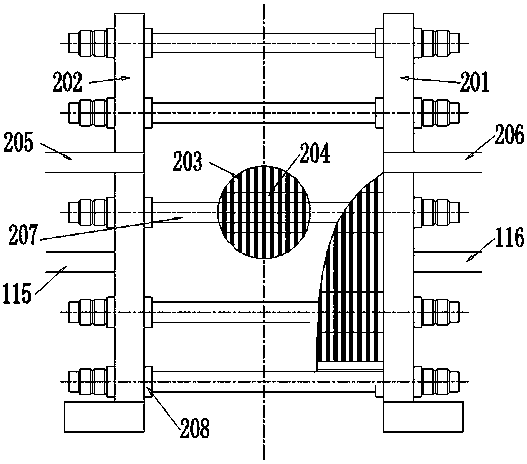

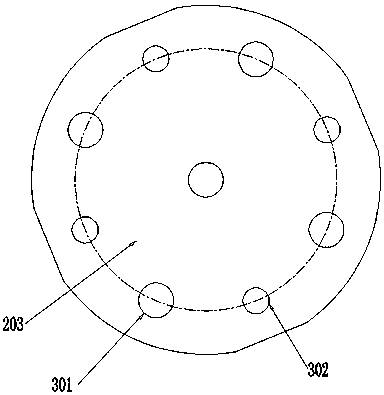

[0030] The hydrogen energy mixed gas production equipment includes an electrolyzer 101, a heat exchanger 103, a primary gas-liquid separation device 109, a catalyst catalytic mixing device 110, a secondary gas-liquid separation device 111, and a gas buffer tank 112. The primary gas The water inlet of the liquid separation device 109 communicates with the water level adjustment water tank 108 through a pipeline, and the water level adjustment controller 106 and the water level adjustment pump 107 are installed on the water inlet pipeline of the water level adjustment water tank 108; The pipeline is communicated with a heat exchanger 103, and the air inlet of the heat exchanger 103 is communicated with the hydrogen-oxygen mixed gas outlet 117 of an electrolytic cell 101 through a pipeline, and an electrolyte circulation is installed on the pipeline that the heat exchanger 103 communicates with the electrolytic c...

Embodiment 2

[0038] Assembly of hydrogen energy mixed gas production equipment:

[0039] The hydrogen energy mixed gas production equipment includes an electrolyzer 101, a heat exchanger 103, a primary gas-liquid separation device 109, a catalyst catalytic mixing device 110, a secondary gas-liquid separation device 111, and a gas buffer tank 112. The primary gas The water inlet of the liquid separation device 109 communicates with the water level adjustment water tank 108 through a pipeline, and the water level adjustment controller 106 and the water level adjustment pump 107 are installed on the water inlet pipeline of the water level adjustment water tank 108; The pipeline is communicated with two heat exchangers 103, and the cooling water outlet and the cooling water inlet between the two heat exchangers 103 are communicated by pipelines, and the air inlet of each heat exchanger 103 is connected with the oxygen hydrogen of an electrolyzer 101 by pipelines. The mixed gas outlet 117 commu...

Embodiment 3

[0047] Assembly of hydrogen energy mixed gas production equipment:

[0048] The hydrogen energy mixed gas production equipment includes an electrolyzer 101, a heat exchanger 103, a primary gas-liquid separation device 109, a catalyst catalytic mixing device 110, a secondary gas-liquid separation device 111, and a gas buffer tank 112. The primary gas The water inlet of the liquid separation device 109 communicates with the water level adjustment water tank 108 through a pipeline, and the water level adjustment controller 106 and the water level adjustment pump 107 are installed on the water inlet pipeline of the water level adjustment water tank 108; The pipeline is communicated with three heat exchangers 103, and the cooling water outlet and the cooling water inlet between the three heat exchangers 103 are communicated by pipelines, and the air inlet of each heat exchanger 103 is connected with the oxygen hydrogen of an electrolyzer 101 by pipelines. The mixed gas outlet 117 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com