Multi-wavelength tunable micro-interference measuring method and device thereof

A technology of microscopic interference and measuring device, which is applied to measuring devices, optical devices, instruments, etc., can solve problems to be developed, and achieve the effects of suppressing measurement errors, phase unwrapping errors, and reducing precision requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

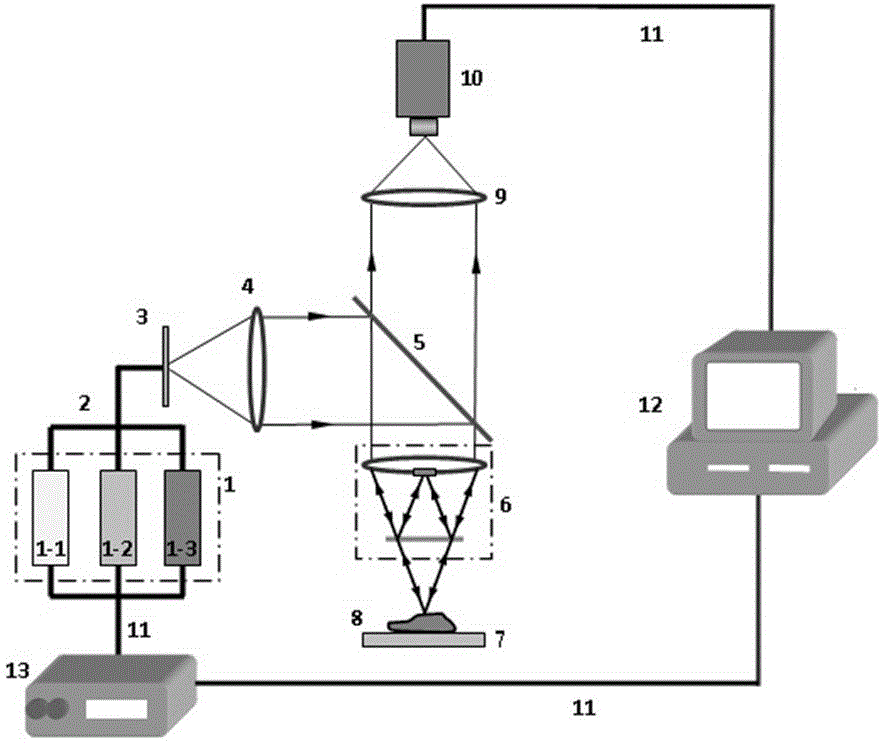

[0031] See attached figure 1, which is a structural schematic diagram of the multi-wavelength tunable microscopic interference measurement device provided in this embodiment. The measurement device includes a multi-wavelength tunable laser 1, a beam combining fiber 2, a ground glass plate 3, a collimating beam expander 4, a beam splitter 5, an interference microscope objective lens 6, a stage 7, an imaging lens 9, a color camera 10, Data transmission control line 11, computer 12, wavelength tuning controller 13. The multi-wavelength tunable laser 1 is regulated by the wavelength tuning controller 13, synchronously or time-sharingly outputs three channels of red, green and blue wavelength tunable laser signals, and combines them into one optical signal through the bundled optical fiber 2, which is focused and coupled to the uniform rotation The surface of the ground glass sheet 3; the ground glass sheet 3 is located at the front focus position of the collimating beam expander ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com