High-resolution crystal orientation acquisition method based on scanning electron microscope

A technology of crystal orientation and scanning electron microscopy, which is applied in the field of characterization, can solve problems such as difficult to achieve accurate calibration of nanoscale fine structures, and achieve the effects of convenient operation, reliable technology, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

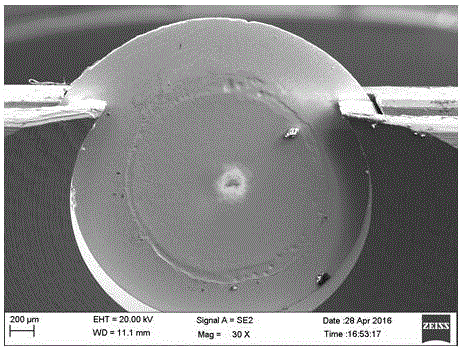

[0022] 1) Preparation of metal samples for detection

[0023] A metal sample with a thickness of 300 μm was prepared by wire electric discharge cutting; then, the metallographic sandpaper of 200#, 400#, 800#, 1000#, 1500#, 2000# and 2500# was used to grind and thin it step by step to below 90 μm; then Then, at a temperature of -15 °C, in the electrolyte, a double-jet electrolytic instrument was used to perform double-jet thinning electrochemical polishing at a voltage of 10 V for 40 s to prepare a metal sample suitable for detection. Electrolyte, volume fraction is the concentrated perchloric acid of 10% and volume fraction is the mixed solution of absolute ethanol of 90%.

[0024] After treatment, the thickness of the thin area of the prepared metal sample should be 70nm.

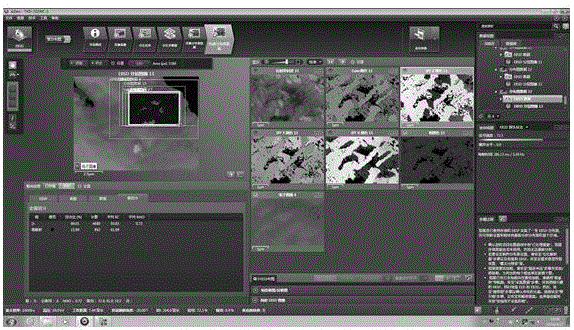

[0025] 2) Place the prepared metal sample on the pre-tilted sample stage of the scanning electron microscope and fix it, adjust the inclination angle between the sample and the electron beam to -18°, th...

Embodiment 2

[0027] 1) Preparation of metal samples for detection

[0028] A metal sample with a thickness of 400 μm was prepared by wire electric discharge cutting; then the metallographic sandpaper of 200#, 400#, 800#, 1000#, 1500#, 2000# and 2500# was used to grind and thin it to below 70 μm step by step; then Then, at a temperature of -20 °C, in the electrolyte, a double-jet electrolytic instrument was used to perform double-jet thinning electrochemical polishing at a voltage of 15 V for 60 s to prepare a metal sample suitable for detection. Electrolyte, volume fraction is the concentrated perchloric acid of 12% and volume fraction is the absolute ethanol mixed solution of 88%.

[0029] After treatment, the thin area thickness of the prepared metal sample should be 80nm.

[0030] 2) Place the prepared metal sample on the pre-tilted sample stage of the scanning electron microscope to clamp and fix it, adjust the inclination angle between the sample and the electron beam to -10°, the ac...

Embodiment 3

[0032] 1) Preparation of metal samples for detection

[0033] A metal sample with a thickness of 450 μm was prepared by wire electric discharge cutting; then, the metallographic sandpaper of 200#, 400#, 800#, 1000#, 1500#, 2000# and 2500# was used to grind and thin it step by step to below 70 μm; then Then, at a temperature of -30 °C, in the electrolyte, a double-jet electrolytic instrument was used to perform double-jet thinning electrochemical polishing at a voltage of 20 V for 100 s to prepare a metal sample suitable for detection. Electrolyte, volume fraction is the concentrated perchloric acid of 8% and volume fraction is the absolute ethanol mixed solution of 92%.

[0034] After treatment, the thickness of the thin area of the prepared metal sample should be 60nm.

[0035] 2) Place the prepared metal sample on the pre-tilted sample stage of the scanning electron microscope to clamp and fix it, adjust the inclination angle between the sample and the electron beam to -4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com