A preparation method of a highly sensitive stretchable biosensor for in situ detection

An in-situ detection and sensitive technology, applied in the direction of instruments, applications, ceramic products, etc., can solve the problems of low sensitivity, difficult stretching, and insufficient stretching stability of biosensors, and achieve simple and controllable methods, low defect peaks, Effect of high chemisorption and physical enhancement mechanisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

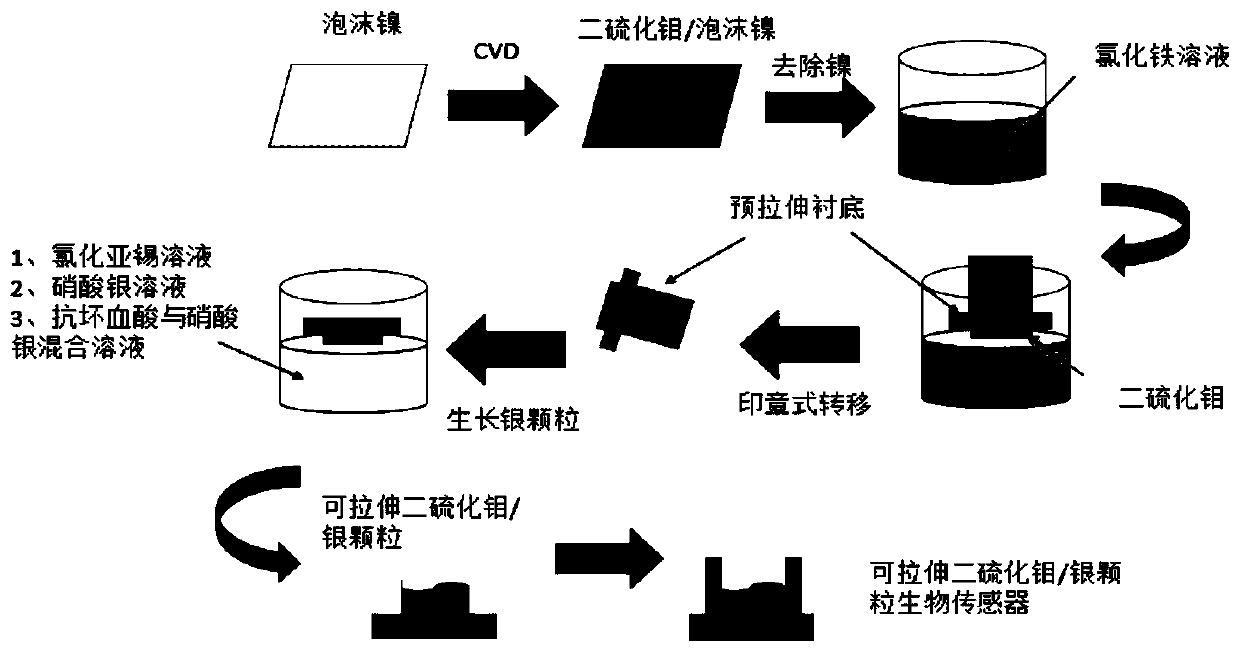

[0055] Three-dimensional molybdenum disulfide is obtained by growing molybdenum disulfide on nickel foam on a three-dimensional three-dimensional substrate, and finally a mixed structure of molybdenum disulfide / silver nanoparticles is obtained, such as figure 1 The preparation roadmap includes the following preparation steps:

[0056] 1. Add 0.25g (NH 4 ) 2 MoS 4 Add to 20ml of dimethylformamide (DMF) to form a concentration of 1.25wt% and sonicate for 20min.

[0057] 2. Take the nickel foam with a size of 8cm×8cm and wash it in acetone.

[0058] 3. Dry at 80°C for 10 minutes.

[0059] 4. Dip the dried nickel foam in (NH 4 ) 2 MoS 4 Formed in solution (NH 4 ) 2 MoS 4 film.

[0060] 5. Dry at 120°C for 30 minutes.

[0061] 6. Place in a tube furnace.

[0062] 7. Turn on the vacuum pump to pump the air pressure of the tube furnace to the ultimate vacuum state of 3×10 -6 Torr;

[0063] 8. Keep vacuum 3×10 -6 After Torr for 15 minutes (the effect of vacuum for 15 m...

Embodiment 2

[0089] The three-dimensional molybdenum disulfide is obtained by growing molybdenum disulfide on the copper foam of the three-dimensional substrate, and finally the mixed structure of molybdenum disulfide / silver nanoparticles is obtained, including the following preparation steps:

[0090] 1. Add 0.25g (NH 4 ) 2 MoS 4 Add to 20ml of dimethylformamide (DMF) to form a concentration of 1.25wt% and sonicate for 20min.

[0091] 2. Take the copper foam with a size of 7cm×8cm and place it in acetone for cleaning.

[0092]3. Dry at 80°C for 10 minutes.

[0093] 4. Dip the dried copper foam in (NH 4 ) 2 MoS 4 Formed in solution (NH 4 ) 2 MoS 4 film.

[0094] 5. Dry at 120°C for 30 minutes.

[0095] 6. Place in a tube furnace.

[0096] 7. Turn on the vacuum pump to pump the air pressure of the tube furnace to the ultimate vacuum state of 3×10 -6 Torr;

[0097] 8. Keep vacuum 3×10 -6 After 15 minutes of Torr (the effect of vacuum for 15 minutes is to remove impurities, air...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com