Irradiation-resistant graphene coatings with enhanced corrosion resistance and thermal conductivity

A graphene and heat conduction technology, applied in the direction of graphene, coating, covering/external coating, etc., can solve problems such as gaps, increase temporary storage, increase temporary storage capacity and safety, increase corrosion resistance and The effect of thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

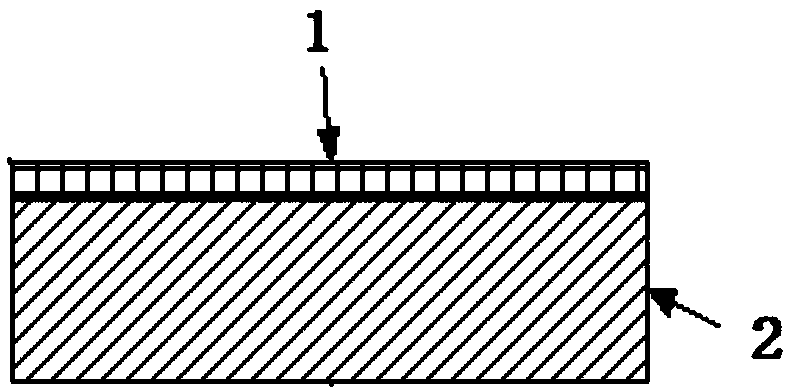

[0034] The radiation-resistant graphene coating with enhanced corrosion resistance and thermal conductivity according to the present invention, such as figure 2 As shown, the graphene coating 1 has a thickness of 1-10 μm (for example, 1 μm, 5 μm, or 10 μm), and is coated on the outer surface of the high-level waste glass solidified body container 2, the high-level waste glass solidified body container It is an austenitic stainless steel material.

[0035] The thickness of the high-level waste glass solidified body container is 2-10mm (for example: 2mm, 6mm or 10mm).

Embodiment 2

[0037] According to the present invention, a high-level radioactive waste glass solidified body container with a radiation-resistant graphene coating that enhances corrosion resistance and thermal conductivity is coated with the outer surface of the high-level waste glass solidified body container 2 Graphene coating 1, the thickness of the graphene coating is 1-10 μm (for example: 1 μm, 5 μm or 10 μm), and the high-level waste glass solidified body container is made of austenitic stainless steel.

[0038] According to the present invention, a high-level radioactive waste glass solidified body container with a radiation-resistant graphene coating that enhances corrosion resistance and thermal conductivity has a thickness of 2~ 10mm (for example: 2mm, 6mm or 10mm).

Embodiment 3

[0040] The method for preparing any radiation-resistant graphene coating with enhanced corrosion resistance and thermal conductivity described in embodiment 1 or embodiment 2 includes the following steps:

[0041] (a) A certain amount of graphene oxide is added to a certain amount of aqueous solution, and the graphene is uniformly dispersed in the aqueous system through radiation oxidation treatment and part of the graphene oxide is reduced to form a graphene dispersion; the radiation oxidation treatment In order to irradiate gamma rays at a dose of 800Gy / h, the irradiation time is 50 hours. The specific mass ratio of the graphene oxide and water is 1:8×10 6 .

[0042] (b) Surface treatment (for example: sanding, sandblasting, or electroplating) on the outer surface of the glass solidified container containing high-level radioactive waste to remove the oxide layer on the surface of austenitic stainless steel;

[0043] (c) coating the graphene oxide obtained in step (a) on the surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| carrier mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com