Aerogel ball and preparation method thereof

An aerogel pellet and aerogel technology, which is applied in the field of nanoporous materials, can solve the problems of difficult to control the size of aerogel pellets, low strength, complicated operation, etc. simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

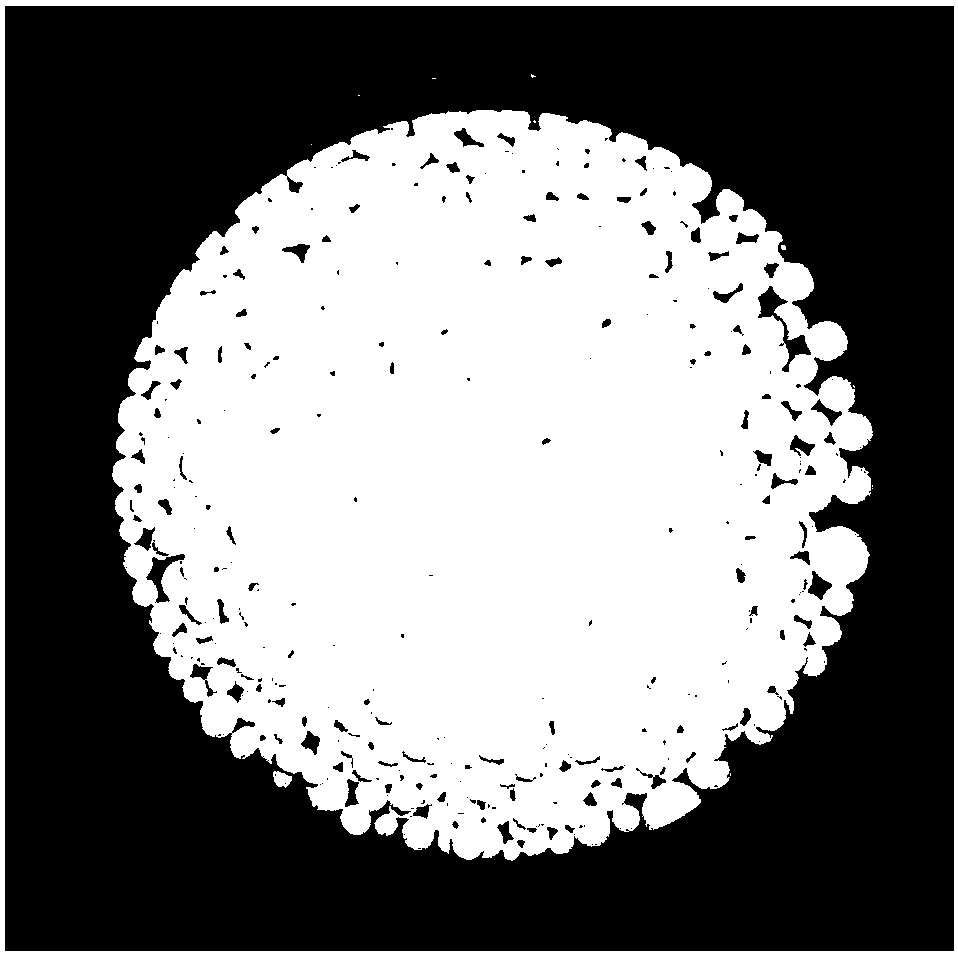

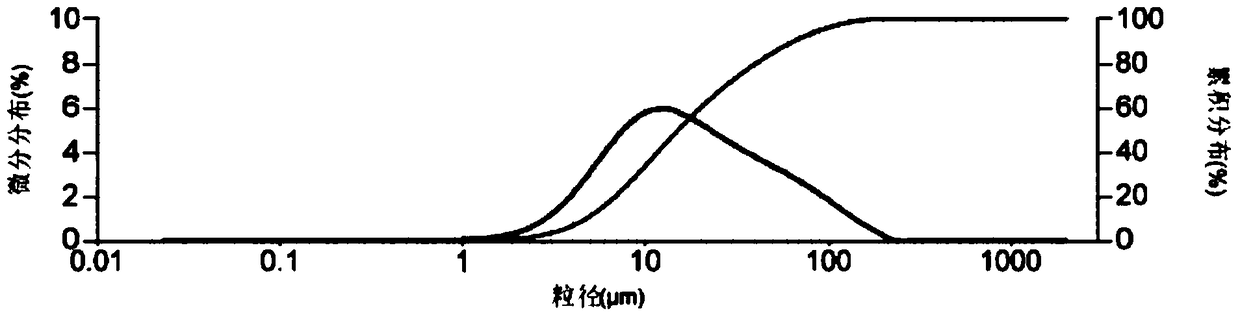

[0041] 1) Silica airgel powder (its particle size distribution and morphology can be referred to Figure 3-Figure 4 ) and water-based polyurethane are mixed at a mass ratio of 1:3, and about 0.1wt% of hydroxyethyl cellulose is added to prepare water-based slurry;

[0042] 2) Add the water-based slurry into a container that can squeeze and drip the slurry, and the diameter of the container is about 2mm;

[0043] 3) Spread the silica powder on a flat plate to form a platform, and the thickness of the airgel powder on the flat plate is about 1 mm;

[0044] 4) Drop the aqueous slurry in the container onto the stage to obtain airgel pellets. The rotation speed of the container is 5r / s (the axis is vertically set and the opening is downward). The particle diameter range of the gel ball is about 2mm.

[0045] 5) Dry the airgel ball prepared in step 4) in an oven at 30-70°C under normal pressure to obtain a dried airgel ball with a specific surface area of 700m 2 / g, with a nanom...

Embodiment 2

[0047] 1) Silica airgel powder and water-based polyurethane are mixed in a mass ratio of 1:4, and 0.5 wt% of hydroxypropyl cellulose is added to prepare water-based slurry;

[0048] 2) Add the aqueous slurry prepared above into a container that can squeeze and drip the slurry, and the diameter of the container is about 3mm;

[0049] 3) Spread the silica powder flat on a carrier platform, the thickness of the airgel powder on the flat plate is 1.5mm;

[0050] 4) Drop the slurry in the container onto the carrier covered with silica powder as described in 3) to obtain airgel pellets. The rotation speed of the container is 7r / s (the axis is vertically set , opening downward), the particle size range of airgel balls is about 3mm;

[0051] 5) Dry the airgel balls prepared in step 4) in an oven at 30-70°C under normal pressure to obtain dried airgel balls with a particle size of about 3 mm and a specific surface area of 800 m 2 / g, with a nano-sized continuous pore structure, the f...

Embodiment 3

[0053] 1) Silica powder and water-based epoxy resin are mixed in a mass ratio of 1:4, and 0.5 wt% of hydroxypropyl cellulose is added to prepare water-based slurry;

[0054] 2) Add the aqueous slurry prepared above into a container that can squeeze and drip the slurry, and the diameter of the container is 5mm;

[0055] 3) Spread the silica powder on a carrier platform, the thickness of the airgel powder on the plate is 1.8mm;

[0056] 4) Drop the slurry in the container onto the stage covered with silica powder as described in 3) to obtain airgel pellets, and the rotation speed of the container is 4r / s (the axis is vertical setting), the particle size of the ball can be controlled by adjusting the slurry outlet of the container, and the particle size range of the airgel ball is about 5mm;

[0057] 5) Dry the prepared airgel balls in an oven at 30-70°C under normal pressure to obtain dried airgel balls with a particle size range of 5 mm and a specific surface area of 100 m ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com