Method for manufacturing embossed solvent-free polyurethane synthetic leather

The technology of a solvent-free polyurethane and a manufacturing method is applied in the manufacture of polyurethane synthetic leather and the manufacture of embossed solvent-free polyurethane synthetic leather. The effect of simplicity, low labor cost, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] 1. Ingredients and preparation of component A

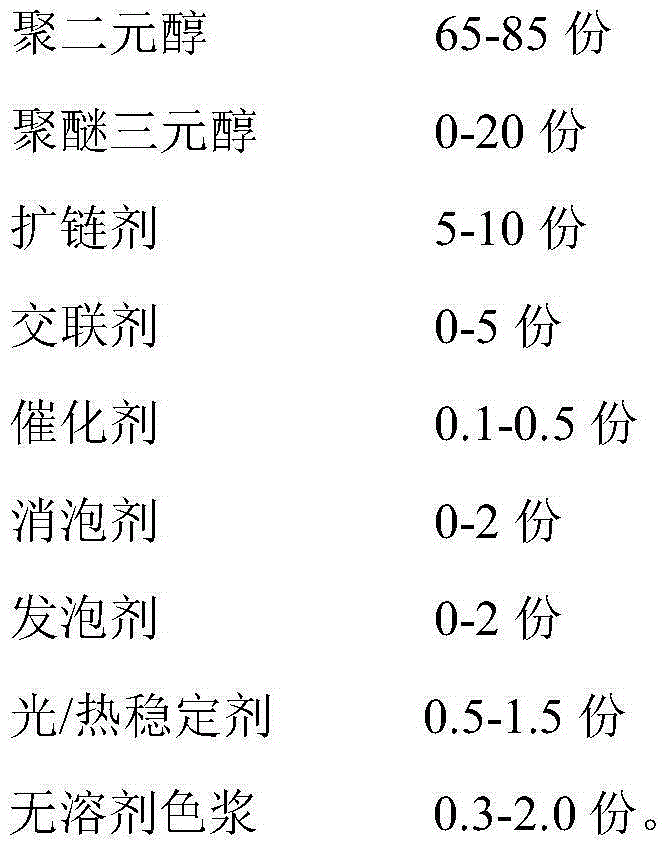

[0062] The batching of component A is constituted as follows by mass parts:

[0063]

[0064] SP-2013 is a polyester diol with a number average molecular weight of 2000 produced by Hefei Amway Polyurethane New Material Co., Ltd. GY-5000E is a polyoxypropylene triol with a number average molecular weight of 5000 produced by Kunshan Guodu Chemical Co., Ltd., EG, BDO and Glycerol is commercially available, BiCAT 8108 is an organic bismuth catalyst from a leading chemical company in the United States, BYK-060N is a high-efficiency silicone defoamer from BYK Chemical Company in Germany, and UV-1 is produced by Kunshan Zhongxing Dyestuff Chemical Co., Ltd. Chisorb 292 is the light stabilizer of Taiwan Double Bond Chemical Co., Ltd., Chinox 1010 is the antioxidant of Taiwan Double Bond Chemical Co., Ltd., and BLPT 3751 is the solvent-free black pulp of Zhejiang Deep Blue Textile Technology Co., Ltd.;

[0065] The preparation ...

Embodiment 2

[0087] 1. Ingredients and preparation of component A

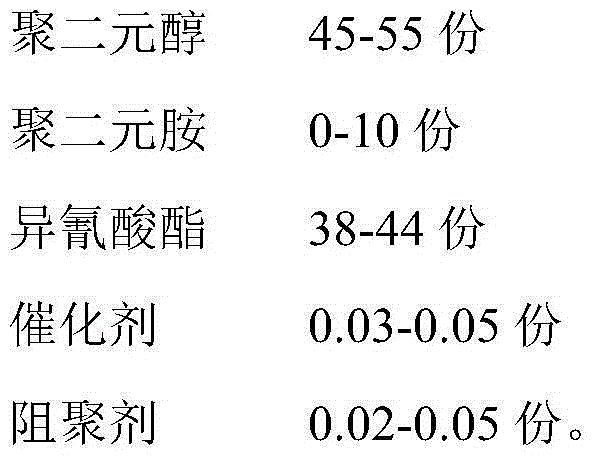

[0088] The batching of component A is constituted as follows by mass parts:

[0089]

[0090] DDL-2000D is the 2000 molecular weight polyoxypropylene diol of Zibo Dexin Federal Chemical Company, GY-5000E is the 5000 molecular weight polyoxypropylene triol of Kunshan Guodu Chemical Co., Ltd., EG, BDO and TMP are commercially available products, BiCAT 8124 is an organic bismuth catalyst from American Leading Chemicals Co., Ltd., BYK-060N is an organic silicon defoamer from BYK, Germany, Chisorb 320 is an ultraviolet absorber from Taiwan Double Bond Chemical Co., Ltd., and Chisorb 770 is a product from Taiwan Double Bond Chemical Co., Ltd. The company's light stabilizer, Chinox 1010 is the antioxidant of Taiwan Double Bond Chemical, Chinox 168 is the auxiliary antioxidant of Taiwan Double Bond Chemical, and BLPT 3751 is the solvent-free black pulp of Zhejiang Deep Blue Textile Technology Co., Ltd.

[0091] The preparation...

Embodiment 3

[0113] 1. Ingredients and preparation of component A

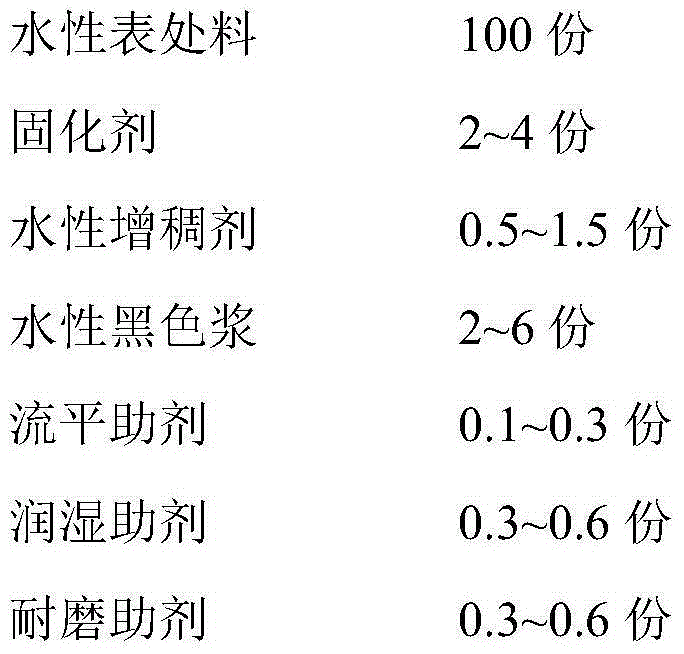

[0114] The batching of component A is constituted as follows by mass parts:

[0115]

[0116] PTMEG-2000 is the polytetrahydrofuran diol of 2000 molecular weight of BASF company, and GY-3000E is the polyoxypropylene triol of 3000 molecular weight of Kunshan Guodu Chemical Company, and EG, HG, diethanolamine are all commercially available products, and Borchi Kat 24 is OMG The metal salt catalyst of Borchers Company, Chisorb P is the ultraviolet absorber of Taiwan Double Bond Chemical Co., Ltd., Tinuvin 5050 is the light stabilizer of BASF Company, Chinox 3114 is the antioxidant of Taiwan Double Bond Chemical, BLPT 3751 is the light Solvent-free black pulp from Spin Technology Co., Ltd.;

[0117] The preparation process of component A is as follows:

[0118] Put polytetrahydrofuran glycol PTMEG-2000, polyoxypropylene triol GY-3000E, ethylene glycol EG, 1,6-hexanediol HG, and diethanolamine into the reaction kettle, sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com