Preparation method for three-dimensional network structure flocculation material structured by bacterial cellulose

A bacterial cellulose, three-dimensional network technology, applied in the field of environmental engineering, to achieve the effect of expanding the scope of application, wide sources of materials, and important economic and social environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

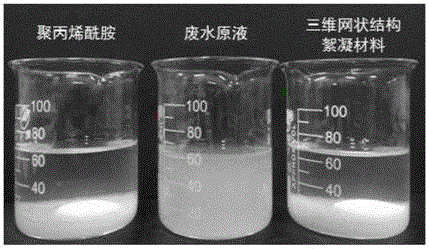

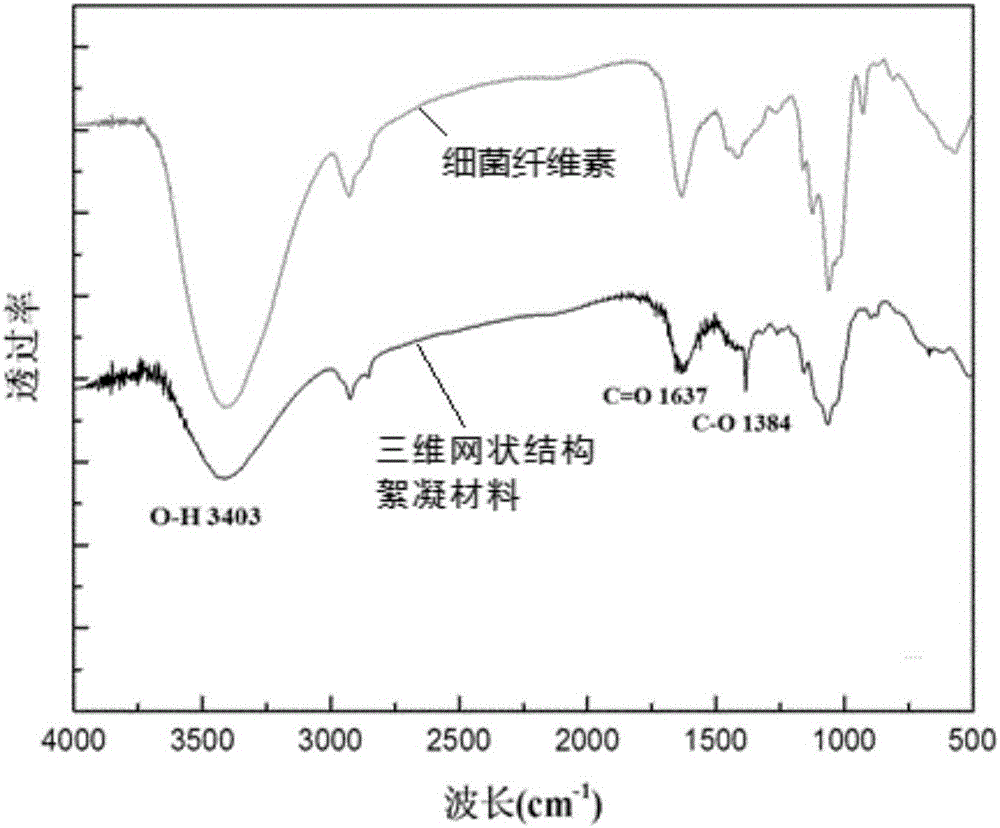

Image

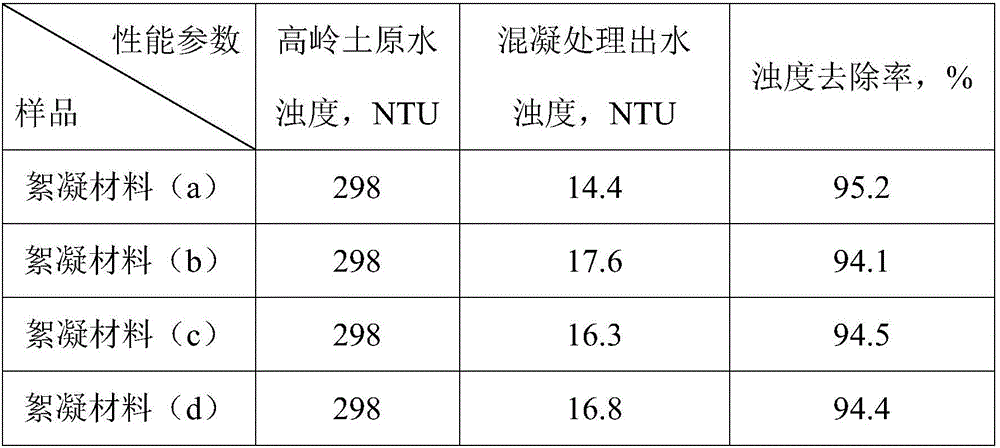

Examples

Embodiment 1

[0022] 1) Add the bacterial cellulose material produced by Sarcina to the mixed solution of 8wt% sodium hydroxide and 10wt% urea at a mass ratio of 15:1 between the mixed solution of sodium hydroxide and urea and the mixed solution of bacterial cellulose material, and place it after fully stirring- Freeze at 10°C for 80 minutes, take out to obtain bacterial cellulose solution;

[0023] 2) Stir the bacterial cellulose solution obtained in step 1) at 35°C under light-shielding conditions at a mass ratio of sodium periodate to cellulose material of 0.2:1, add sodium periodate to oxidize for 110 minutes, and then The mass ratio of alcohol and bacterial cellulose material is 2:1, adding ethylene glycol and reacting for 60 minutes to remove residual sodium periodate; removing the shading device and stirring and reacting for 6 hours at room temperature to obtain carboxycellulose solution;

[0024] 3) Centrifuge the carboxycellulose solution obtained from the reaction in step 2), wash...

Embodiment 2

[0026] 1) The bacterial cellulose material produced by rhizobia is added to the mixed solution of 8wt% sodium hydroxide and 10wt% urea according to the mass ratio of sodium hydroxide and urea mixed solution to bacterial cellulose material 20:1, fully stirred and placed -10 Freeze at ℃ for 70 minutes, take out to obtain bacterial cellulose solution;

[0027] 2) Stir the bacterial cellulose solution obtained in step 1) at 40°C under light-shielding conditions at a mass ratio of sodium periodate to cellulose material of 0.1:1, add sodium periodate to oxidize for 90 minutes, and then press ethylene di The mass ratio of alcohol and bacterial cellulose material is 1:1, adding ethylene glycol and reacting for 30 minutes to remove residual sodium periodate; removing the shading device and stirring and reacting at room temperature for 7 hours to obtain carboxycellulose solution;

[0028] 3) Centrifuge the carboxycellulose solution obtained from the reaction in step 2), wash until neutr...

Embodiment 3

[0030] 1) Add the bacterial cellulose material produced by Sarcina to the mixed solution of 8wt% sodium hydroxide and 10wt% urea at a mass ratio of 18:1 between the mixed solution of sodium hydroxide and urea and the mixed solution of bacterial cellulose material, and place it after fully stirring- Freeze at 10°C for 65 minutes, take out to obtain bacterial cellulose solution;

[0031] 2) Stir the bacterial cellulose solution obtained in step 1) at 40°C under light-shielding conditions at a mass ratio of sodium periodate to bacterial cellulose material of 0.18:1 and add sodium periodate to oxidize it for 105 minutes, then press B The mass ratio of diol to cellulose material is 1.5:1, adding ethylene glycol and reacting for 70 minutes to remove residual sodium periodate; removing the shading device and stirring and reacting for 7 hours at room temperature to obtain carboxycellulose solution;

[0032] 3) Centrifuge the carboxycellulose solution obtained from the reaction in step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com