Antireflective organic glass and preparation method thereof

A technology of plexiglass and organic solvent, which is applied in the field of anti-reflection plexiglass and its preparation, which can solve the problems of limited application and low ultraviolet light transmittance, and achieve the effects of improving uniformity, reducing agglomeration, and improving dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

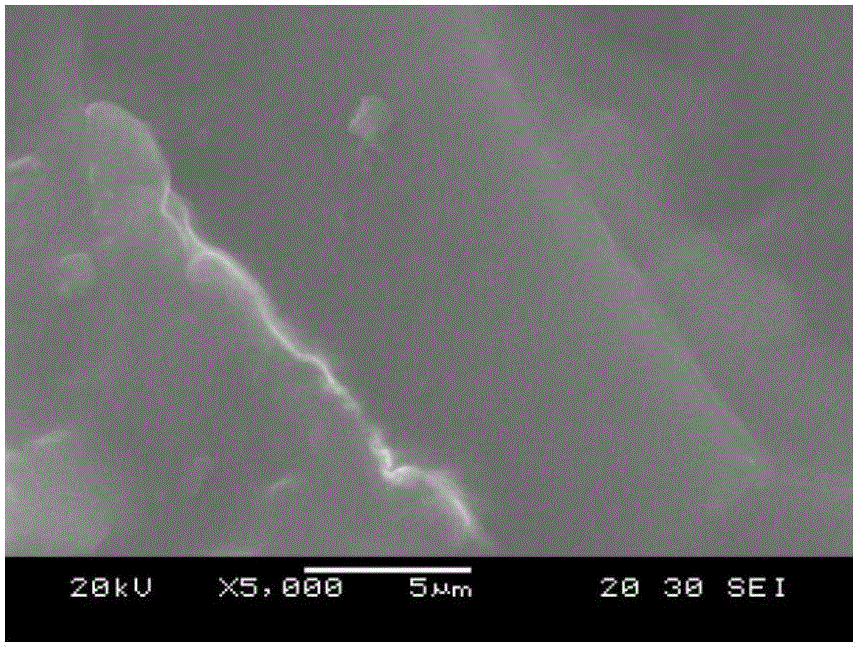

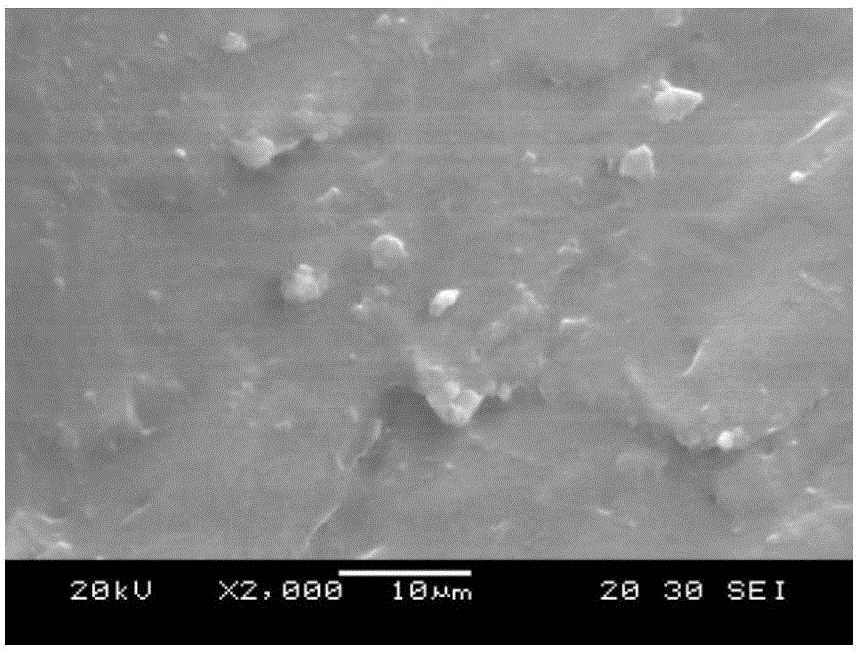

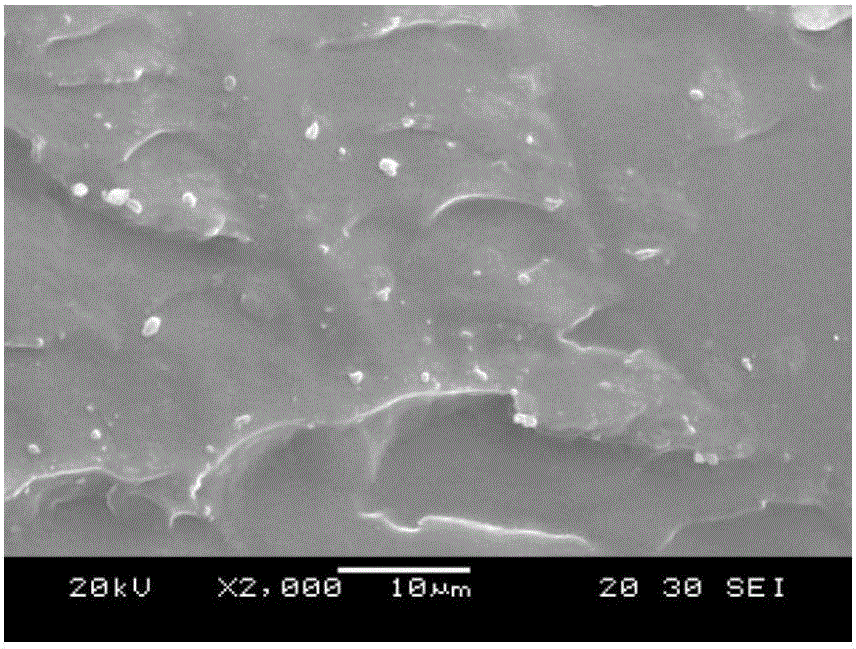

Image

Examples

Embodiment 1

[0035] (1) Preparation of mixed solution: at room temperature, 0.5g methyl methacrylate, 2g acrylic acid, 0.02g azobisisobutylcyanide, 1g nano-SiO 2 Dissolve in 40g of acetone, and mix uniformly to obtain a mixed solution.

[0036] (2) The mixed solution and the plexiglass substrate are sprayed and mixed: 15g of the plexiglass substrate is put into a high-speed mixer, and the mixed solution prepared in (1) is sprayed on the plexiglass substrate at intervals, spraying once every 5 minutes, every Spray for 30 seconds for the first time, and then mix for another 30 minutes after all the mixed solution is sprayed to ensure that the mixed solution is evenly mixed with the plexiglass substrate, and plexiglass A is finally obtained.

[0037] (3) Dry the plexiglass to remove the solvent: Dry the plexiglass A prepared in (2) with an electric blast drying oven to remove the organic solvent. The drying temperature is 80° C. and the drying time is 4 hours to obtain the plexiglass B. .

...

Embodiment 2

[0043] (1) Preparation of mixed solution: at room temperature, 1g methyl methacrylate, 1.2g KH570, 0.04g azobisisobutylcyanide, 2g nano-SiO 2 Dissolve in 80g of acetone, and mix uniformly to obtain a mixed solution.

[0044] (2) The mixed solution and the plexiglass substrate are sprayed and mixed: 30g of the plexiglass substrate is put into a high-speed mixer, and the mixed solution prepared in (1) is sprayed on the plexiglass substrate at intervals, spraying once every 5min, every Spray for 30 seconds for the first time, and then mix for another 30 minutes after all the mixed solution is sprayed to ensure that the mixed solution is evenly mixed with the plexiglass substrate, and plexiglass A is finally obtained.

[0045] (3) Dry the plexiglass to remove the solvent: Dry the plexiglass A prepared in (2) with an electric blast drying oven to remove the organic solvent. The drying temperature is 80° C. and the drying time is 5 hours to obtain the plexiglass B. .

[0046] (4) ...

Embodiment 3

[0051] (1) Preparation of mixed solution: at room temperature, 1.5g methyl methacrylate, 6g maleic anhydride, 0.06g azobisisobutylcyanide, 3g nanometer SiO 2 Dissolve in 160g of acetone, and mix uniformly to obtain a mixed solution.

[0052] (2) The mixed solution and the plexiglass substrate are sprayed and mixed: 45g of the plexiglass substrate is put into a high-speed mixer, and the mixed solution prepared in (1) is sprayed on the plexiglass substrate at intervals, spraying once every 5 minutes, every Spray for 30 seconds for the first time, and then mix for another 30 minutes after all the mixed solution is sprayed to ensure that the mixed solution is evenly mixed with the plexiglass substrate, and plexiglass A is finally obtained.

[0053] (3) Dry the organic glass to remove the solvent: Dry the organic glass A prepared in (2) with an electric blast drying oven to remove the organic solvent at a drying temperature of 80° C. to obtain the organic glass B.

[0054] (4) Pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com