Encapsulating material of capacitor

A technology for potting materials and capacitors, applied in the field of capacitors, can solve the problems affecting the service life of capacitors, not cold-resistant, inelastic, etc., and achieve the effect of improving adhesion, increasing elasticity and recovery, and high expansion capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

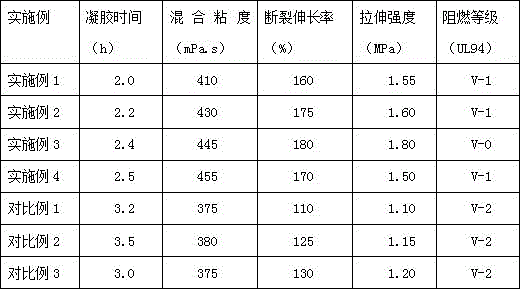

Examples

Embodiment 1

[0010] A capacitor potting material, the preparation method of which is as follows:

[0011] (1) Take 3.0 parts of attapulgite and put it into a high-energy ball mill, and grind it into fine powder;

[0012] (2) Take ethylene glycol and cyanate, add them to the mechanical stirring tank in turn, stir at a constant speed, the stirring speed is 3000r / min, the temperature of the reaction tank is 65°C, after stirring for 30min, add attapulgite ground into powder, continue Stir for 1h, and the stirring temperature is 70~80°C to obtain modified polyurethane;

[0013] (3) Take 8.0 parts of modified polyurethane, put it in a reaction kettle, add 3.0 parts of silicone flame retardant, 1.0 parts of asphalt, 1.5 parts of silicone gel in sequence, stir for 30 minutes, the stirring speed is 1500r / min, and the temperature is 70℃ , that is, the potting material.

Embodiment 2

[0015] A capacitor potting material, the preparation method of which is as follows:

[0016] (1) Take 3.5 parts of attapulgite and put it into a high-energy ball mill, and grind it into fine powder;

[0017] (2) Take ethylene glycol and cyanate, add them to the mechanical stirring tank in turn, stir at a constant speed, the stirring speed is 3000r / min, the temperature of the reaction tank is 65°C, after stirring for 30min, add attapulgite ground into powder, continue Stir for 1h, and the stirring temperature is 70~80°C to obtain modified polyurethane;

[0018] (3) Take 9.0 parts of modified polyurethane, put it in the reaction kettle, add 3.5 parts of silicone flame retardant, 1.5 parts of asphalt, 2.0 parts of silicone gel, 3.2 parts of silicone flame retardant, stir for 30 minutes, and the stirring speed is 1500r / min, the temperature is 70°C, and the potting material is obtained.

Embodiment 3

[0020] A capacitor potting material, the preparation method of which is as follows:

[0021] (1) Take 4.5 parts of attapulgite and put it into a high-energy ball mill, and grind it into fine powder;

[0022] (2) Take ethylene glycol and cyanate, add them to the mechanical stirring tank in turn, stir at a constant speed, the stirring speed is 3000r / min, the temperature of the reaction tank is 65°C, after stirring for 30min, add attapulgite ground into powder, continue Stir for 1h, and the stirring temperature is 70~80°C to obtain modified polyurethane;

[0023] (3) Take 9.5 parts of modified polyurethane, put it in the reaction kettle, add 3.5 parts of silicone flame retardant, 1.8 parts of asphalt, 2.8 parts of silicone gel, 3.5 parts of silicone flame retardant, stir for 30 minutes, and the stirring speed is 1500r / min, the temperature is 70°C, and the potting material is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com