Liquid crystal alignment agent, liquid crystal alignment film, and liquid crystal display

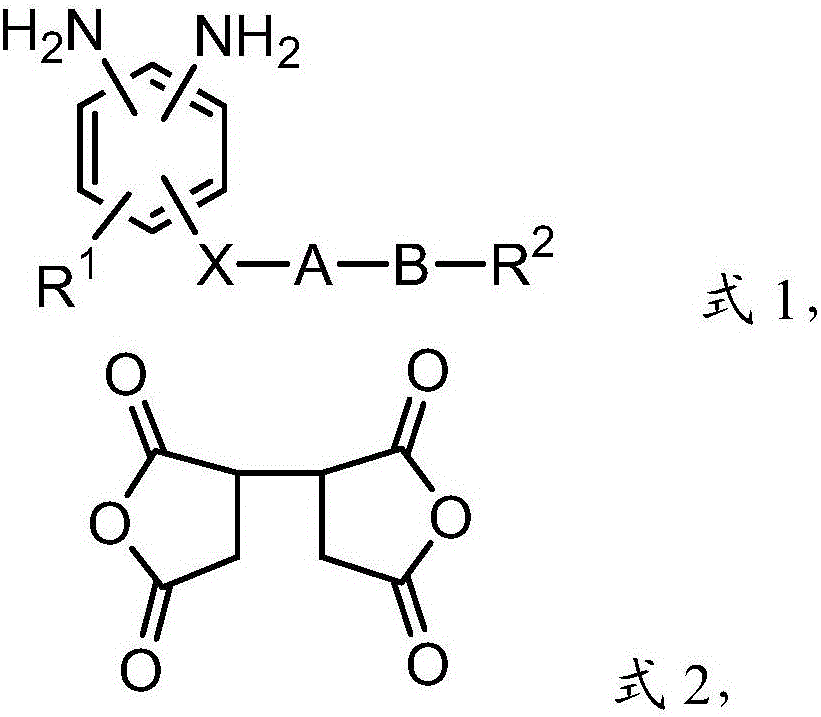

A liquid crystal alignment agent and a technology for liquid crystal alignment, which are applied in the directions of liquid crystal materials, instruments, chemical instruments and methods, etc., can solve the problems of liquid crystal displays such as uneven dot-like hue, uneven alignment of drip marks, and inability to uniformly disperse monomers. , to achieve good display quality, avoid uneven diffusion, and fast response.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

[0069] The synthesis method of the compound represented by the aforementioned formula 6 is as follows.

[0070] 1-fluoro-2,4-dinitrobenzene (1-fluoro-2,4-dinitrobenzene, DNFB) (102.36g) and tetrahydrofuran (tetrahydrofuran, THF) (500ml) were mixed in a 1000ml round bottom bottle, at this time Appears as a yellow clear liquid. Next, under continuous stirring with a magnet, slowly add 1-phenylpiperazine (1-phenylpiperazine, PP) (81.12 g) using an addition funnel, at this time, the yellow clear liquid gradually turns into an orange-red liquid and is accompanied by the precipitation of an orange-yellow solid . After the feeding was completed, the external temperature was raised to 80° C. using an oil bath, and the internal temperature was 65° C. and reflux was carried out for 6 hours while stirring continuously. After returning to temperature, the orange liquid was slowly dropped into isopropanol (IPA) (1500ml) to precipitate and wash off excess starting material and impurities....

Synthetic example 2

[0075] The synthesis method of the compound represented by the aforementioned formula 7 is as follows.

[0076]

[0077] Synthesis of compound (b):

[0078] Methyl 3,5-dinitrobenzoate (MDNBA) (1.1eq, 248.75g) and compound (a) (1.0eq, 244.38g) were put into a 3L reactor. Next, under a nitrogen atmosphere, THF (1038.02 g) was added to dissolve MDNBA and compound (a), and then mechanically stirred for 10 minutes at a stirring speed of 200 rpm. After that, N,N'-dicyclohexylcarbodiimide (N,N'-Dicyclohexylcarbodiimide, DCC, CAS=538-75-0) (1.1eq, 226.96g) was added, and the reaction kettle was washed with THF (129.75g) wall. At this point, the solution gradually turned from a clear state to a white turbid state. Next, stirring was carried out for 10 minutes, so that the solution was uniformly white and turbid. After the uniform white turbidity appeared, 4-dimethylaminopyridine (4-dimethylaminopyridine, DMAP, CAS=1122-58-3) (0.1eq, 12.22g) was dissolved in THF (129.75g), and th...

Synthetic example 3

[0083] The synthesis method of the compound represented by the aforementioned formula 8 is as follows.

[0084]

[0085] Synthesis of compound (d):

[0086] Compound (d) was synthesized in the same steps as compound (b), and compound (c) was used instead of compound (a) as a synthetic raw material to obtain white compound (d) (yield: 96%).

[0087] The synthesis of the compound shown in formula 8:

[0088] In a 3L reactor, compound (d) (259.51g) was dissolved in THF (1341.14g), and 5% palladium-carbon catalyst (Pd / C) (12.98g) was added. Next, under the continuous stirring of the obtained mixture by a mechanical stirrer (stirring speed is 200rpm), hydrazine (hydrazine, N 2 h 4 ) (259.51g) was slowly dripped at a rate of about 0.05g / s, and the temperature was raised to about 60 degrees. After the dropwise addition of hydrazine was completed, the stirring reaction was continued for 8 hours. At this point, the solution will turn from a light yellow clear solution to a colo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com