Methanol fuel composite additive favorable for cold boot of compressing ignition engine

A compound additive and methanol fuel technology, applied in the field of fuel additives, to achieve the effect of increasing gasification degree and evaporation rate, simple compounding process, and no three wastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A kind of methanol fuel compound additive that helps compression ignition engine cold start, it is composed of the following components by mass percentage: acetone 8%, methyl acetate 7%, cyclopentane 8.5%, ethylene glycol diethyl ether 11.5% %, 1,1-dimethoxyethane 12%, bromoethane 5%, 2-methyl-2-butene 4.5%, isobutanol 17%, isoamyl alcohol 13%, octanol 7.5%, 4.5% of tert-butyl acetate, 0.75% of 2,6-di-tert-butyl mixed phenol, and 0.75% of N,N'-disalicylidenediamine.

[0029] In this embodiment, the amount of the additive added to the methanol fuel is 2% of the weight of the methanol fuel, which is suitable for the situation where the ambient temperature is above 0°C.

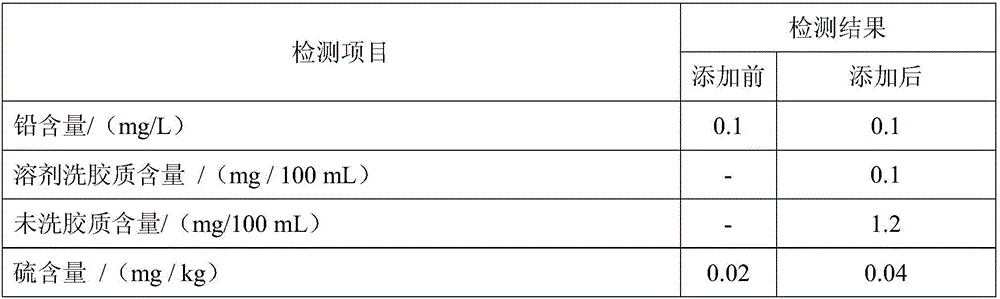

[0030] Table 1. Comparison of methanol fuel performance before and after adding the composite additive of this example

[0031]

[0032]

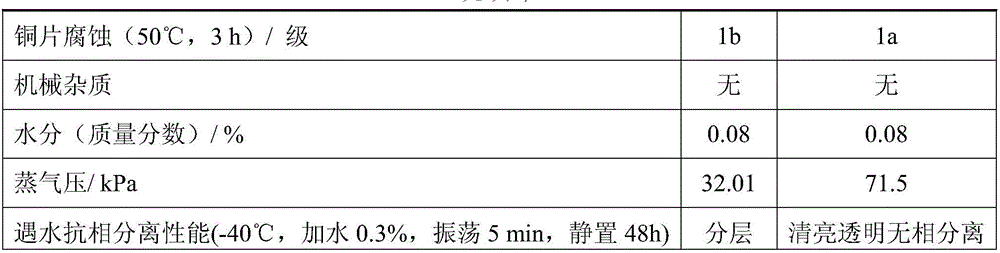

[0033] Table 2. Test results of methanol fuel anti-phase separation performance in water before and after adding the composite additive of this example

[0034...

Embodiment 2

[0039] A kind of methanol fuel compound additive that helps compression ignition engine cold start, it is composed of the following components in terms of mass percentage: acetone 16.6%, methyl acetate 6%, cyclopentane 8%, ethylene glycol diethyl ether 11 %, 1,1-dimethoxyethane 10%, bromoethane 4%, 2-methyl-2-butene 4%, isobutanol 16%, isoamyl alcohol 12%, octanol 7%, 4% tert-butyl acetate, 0.7% 2,6-di-tert-butyl mixed phenol, 0.7% N,N'-disalicylidenediamine.

[0040] In this embodiment, the amount of the additive added to the methanol fuel is 4% of the weight of the methanol fuel, which is applicable to the situation where the external ambient temperature is above -20°C.

[0041] Table 4. Comparison of methanol fuel performance before and after adding the composite additive of this example

[0042]

[0043] Table 5. Test results of methanol fuel anti-phase separation performance in water before and after adding the composite additive of this example

[0044]

[0045] ...

Embodiment 3

[0049] A kind of methanol fuel compound additive that helps compression ignition engine cold start, it is composed of the following components by mass percentage: acetone 30%, methyl acetate 5%, cyclopentane 7%, ethylene glycol diethyl ether 10% %, 1,1-dimethoxyethane 8%, bromoethane 2%, 2-methyl-2-butene 3%, isobutanol 15%, isoamyl alcohol 10%, octanol 6%, 3% tert-butyl acetate, 0.5% 2,6-di-tert-butyl mixed phenol, 0.5% N,N'-disalicylidenediamine.

[0050] In this embodiment, the amount of the additive added to the methanol fuel is 6% of the weight of the methanol fuel, which is applicable to the situation where the external ambient temperature is above -40°C.

[0051] Table 7. Comparison of methanol fuel performance before and after adding the composite additive of this example

[0052]

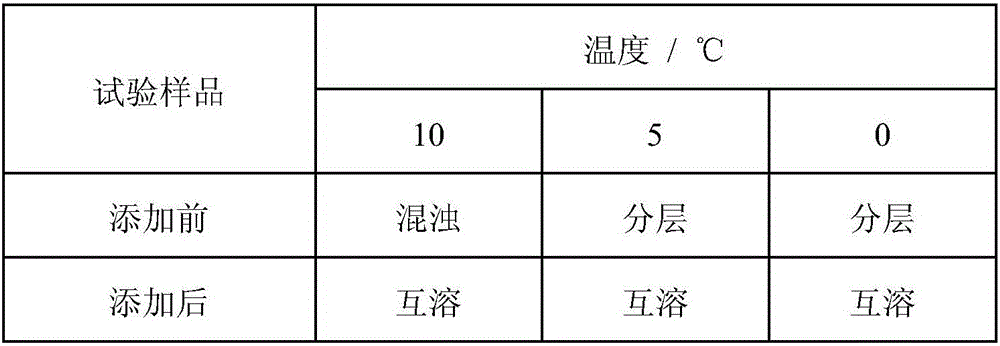

[0053]Table 8. Test results of methanol fuel anti-phase separation performance in water before and after adding the composite additive of this example

[0054]

[0055] Note: Add 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com