A kind of high-efficiency photoautotrophic culture method of Chlorella

A technology for photoautotrophic culture and chlorella, applied in the direction of microorganism-based methods, biochemical equipment and methods, single-cell algae, etc., can solve problems such as energy consumption, consumption, and discomfort of algae, and achieve vitality and improve Growth rate, the effect of prolonging the continuous culture period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

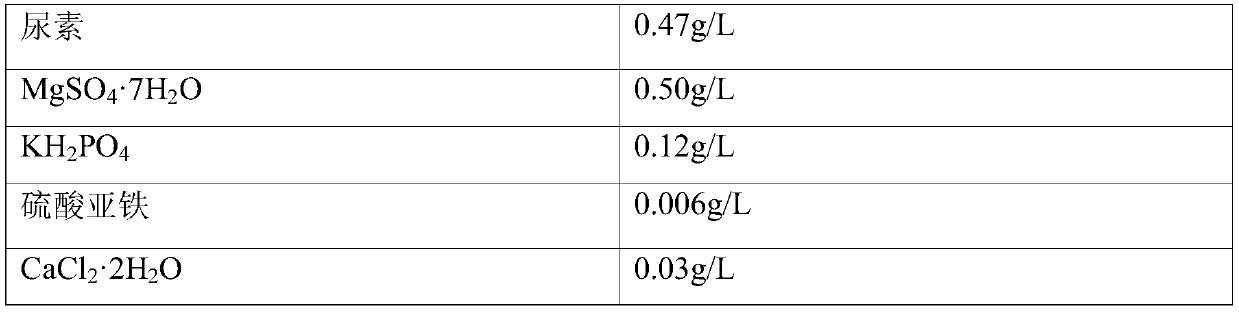

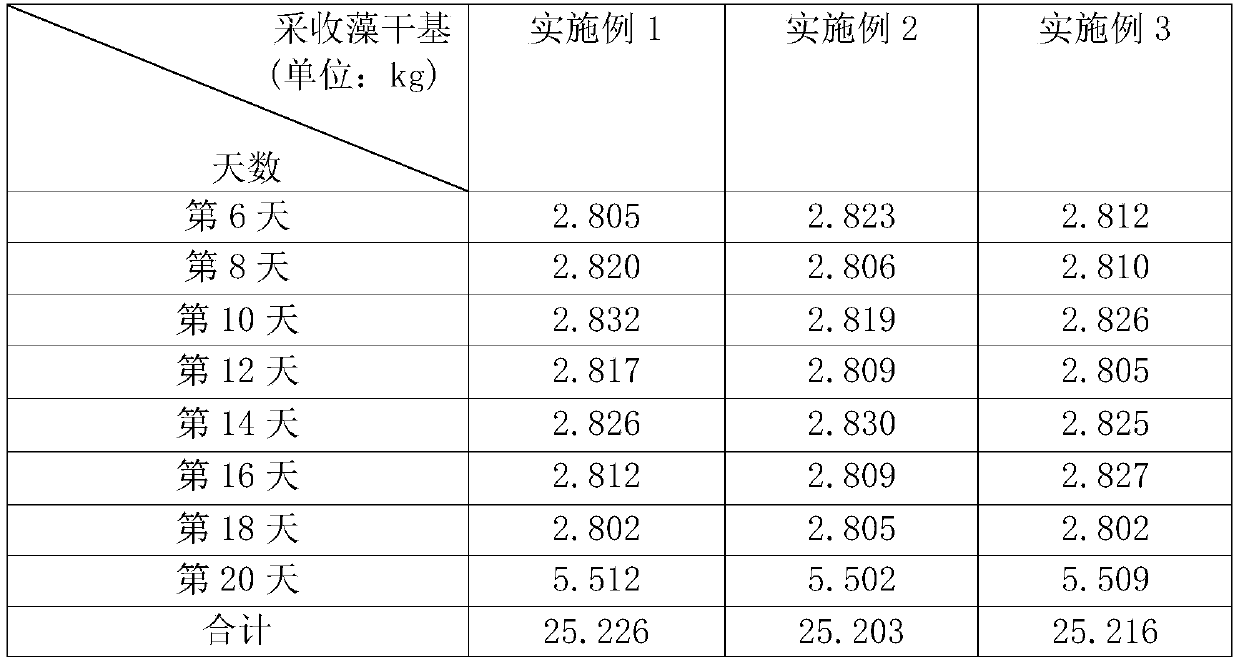

[0016] First, add the nutrient salts in the following table 1 into the tap water. After the components are fully dissolved, they are sterilized by ultraviolet light and added to a 5-ton photobioreactor to inoculate Chlorella, and ensure that the algae cell density is 1 million / milliliters, start chlorella photoautotrophy; autotrophic culture conditions are: use natural light, daytime light intensity is 10-130Klx, photoperiod 12 / 12, air flow rate 1.0L / min, carbon dioxide gas flow rate 0.05L / min, the temperature of the algae liquid is 26-33°C, and the pH is maintained at 7.0-9.0; from the 6th day of cultivation, harvest once every other day, harvest 50% of the algae liquid each time, and then add fresh culture liquid to continue the cultivation , until the 20th day, the culture ended. The harvested chlorella was centrifuged, cleaned, and dried to obtain dry algae powder, and the dry base of the algae and the protein content in the algae were measured. During the entire cultur...

Embodiment 2

[0021] First, add the nutrient salts in the following table 2 components into the tap water. After the components are fully dissolved, they are sterilized by ultraviolet light and added to a 5-ton photobioreactor to inoculate chlorella, and ensure that the algae cell density is 1.2 million / milliliters, start chlorella photoautotrophy; autotrophic culture conditions are: use natural light, daytime light intensity is 10-130Klx, photoperiod 12 / 12, air flow rate 10.0L / min, carbon dioxide gas flow rate 0.5L / min, the temperature of the algae liquid is 26-33°C, and the pH is maintained at 7.0-9.0; from the 6th day of cultivation, harvest once every other day, harvest 50% of the algae liquid each time, and then add fresh culture liquid to continue the cultivation , until the 20th day, the culture ended. The harvested chlorella was centrifuged, cleaned, and dried to obtain dry algae powder, and the dry base of the algae and the protein content in the algae were measured. During the ...

Embodiment 3

[0026] First, add the nutrient salts of the following table 3 components into the tap water. After the components are fully dissolved, they are sterilized by ultraviolet light and added to a 5-ton photobioreactor to inoculate Chlorella, and ensure that the algae cell density is 1.4 million / milliliters, start chlorella photoautotrophy; autotrophic culture conditions are: use natural light, daytime light intensity is 10-130Klx, photoperiod 12 / 12, air volume 5.0L / min, carbon dioxide gas inflow 0.2L / min, the temperature of the algae liquid is 26-33°C, and the pH is maintained at 7.0-9.0; from the 6th day of cultivation, harvest once every other day, harvest 50% of the algae liquid each time, and then add fresh culture liquid to continue the cultivation , until the 20th day, the culture ended. The harvested chlorella was centrifuged, cleaned, and dried to obtain dry algae powder, and the dry base of the algae and the protein content in the algae were measured. During the entire ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com