Preparing method of microporous carbon fiber with high specific surface area

A high specific surface area, microporous carbon technology, applied in the field of porous materials, can solve the problems of long activation step time, complex preparation process, high energy consumption, etc., and achieve the effect of abundant micropores and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

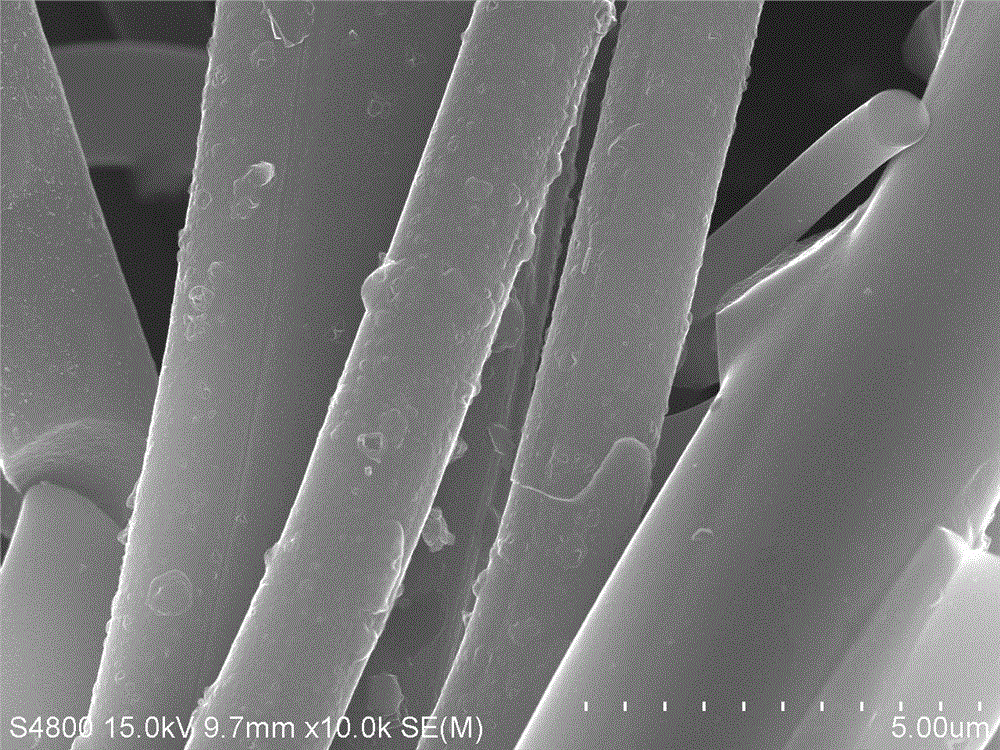

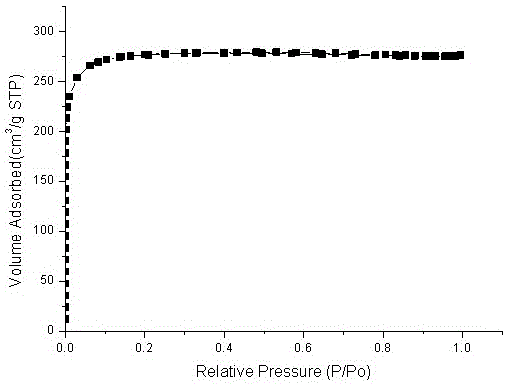

Image

Examples

Embodiment 1

[0019] Embodiment 1: join the thermosetting phenolic resin of 1 weight part, the polyvinyl butyral (PVB) of 0.6 weight part, the pore-forming agent of 0.05 weight part in the ethanol solvent of 10 weight parts, fully stir and disperse to obtain electrospinning silk stock solution;

[0020] The electrospinning stock solution was spun on an electrospinning equipment to obtain fibers (precursor fibers). The electrospinning parameters were: spinning needle G30, spinning voltage 18kV, and spinning distance 20cm; the fibers were cured at 70°C for 8 1 hour, 80°C for 4 hours, 90°C to 110°C for 2 hours per liter of 10°C, 120°C to 150°C for each liter of 10°C for 1 hour, and 160°C for another 2 hours. ; Afterwards, put the cured fiber glue in a tubular carbonization furnace, under the protection of nitrogen, the temperature is raised from room temperature to 700°C at a heating rate of 5°C / min, carbonized at a constant temperature for 180 minutes, and cooled naturally to obtain micropore...

Embodiment 2

[0021] Embodiment 2: join the thermosetting phenolic resin of 1 weight part, the polyvinyl butyral (PVB) of 0.5 weight part, the pore-forming agent of 0.1 weight part in the ethanol solvent of 8 weight parts, fully stir and disperse to obtain electrospun silk stock solution;

[0022] The electrospinning stock solution was spun on an electrospinning equipment to obtain fibers (precursor fibers). The electrospinning parameters were: spinning needle G30, spinning voltage 18kV, and spinning distance 20cm; the fibers were cured at 70°C for 8 1 hour, 80°C for 4 hours, 90°C to 110°C for 2 hours per liter of 10°C, 120°C to 150°C for each liter of 10°C for 1 hour, and 160°C for another 2 hours. ; Afterwards, put the cured fiber glue in a tubular carbonization furnace, under the protection of nitrogen, the temperature is raised from room temperature to 900°C at a heating rate of 5°C / min, carbonized at a constant temperature for 60 minutes, and cooled naturally to obtain micropores with ...

Embodiment 3

[0023] Embodiment 3: join the thermosetting phenolic resin of 1 weight part, the polyvinyl butyral (PVB) of 0.8 weight part, the pore-forming agent of 0.2 weight part in the ethanol solvent of 15 weight parts, fully stir and disperse to obtain electrospinning silk stock solution;

[0024] The electrospinning stock solution was spun on an electrospinning equipment to obtain fibers (precursor fibers). The electrospinning parameters were: spinning needle G30, spinning voltage 18kV, and spinning distance 20cm; the fibers were cured at 70°C for 8 1 hour, 80°C for 4 hours, 90°C to 110°C for 2 hours per liter of 10°C, 120°C to 150°C for each liter of 10°C for 1 hour, and 160°C for another 2 hours. ; Afterwards, put the cured fiber glue in a tubular carbonization furnace, under the protection of nitrogen, the temperature is raised from room temperature to 800°C at a heating rate of 5°C / min, carbonized at a constant temperature for 120 minutes, and cooled naturally to obtain micropores...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com