Preparation method of spray type chitosan aqueous solution wound dressing

A wound dressing and chitosan technology, applied in medical science, bandages, etc., can solve the problems of chemical residues, long film formation time, poor water resistance, etc., and achieve the effect of reducing water content, promoting dissolution, and maintaining fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Using 0.5% acetic acid aqueous solution as a solvent, deacetylation degree of 95%, and chitosan with a viscosity average molecular weight of 100,000 as a raw material, stirring and dissolving to obtain a chitosan solution with a mass percentage concentration of 1%, while using a rotating speed of 10,000rpm The prepared chitosan solution was stirred by a homogenizer, and the sodium hydroxide aqueous solution with a concentration of 1g / L was added dropwise until the pH value of the solution was 7, and the addition of the sodium hydroxide aqueous solution was stopped to obtain a turbid solution of chitosan. The chitosan turbid solution obtained by centrifugation of a high-speed centrifuge with a rotating speed of 10000rpm is used to obtain a chitosan precipitate, and the precipitate is washed with distilled water until the pH value of the washing solution is 7 to obtain a chitosan gel .

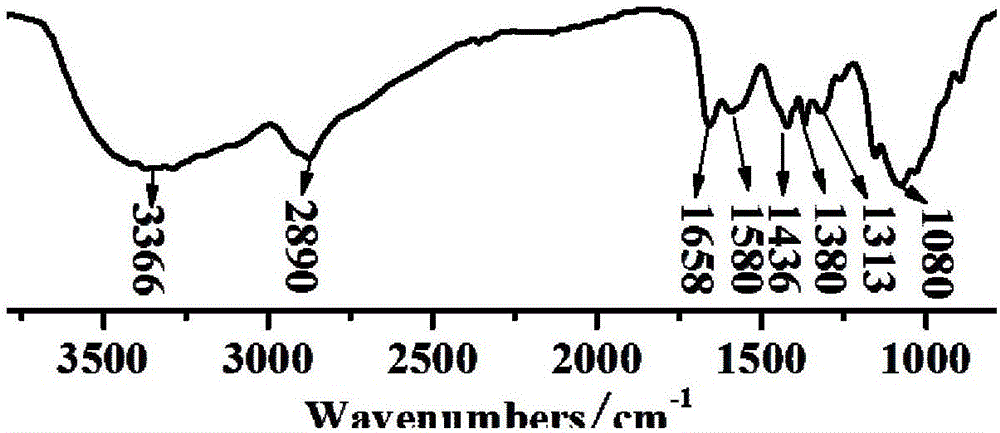

[0043] Get the gel body prepared in Example 1 and dry a little, use infrared spectrom...

Embodiment 2

[0048] Using 0.5% acetic acid aqueous solution as solvent, deacetylation degree ≥ 90%, and chitosan with viscosity-average molecular weight of 100,000 as raw material, stirring and dissolving to obtain a chitosan solution with a mass percentage concentration of 1%. 500rpm, 1000rpm, 5000rpm, 10000rpm, 30000rpm homogenizer stirred the obtained chitosan solution, while adding the sodium hydroxide aqueous solution with a concentration of 1g / L dropwise until the pH value of the solution was 7, stop adding sodium hydroxide aqueous solution to obtain a turbid solution of chitosan; the chitosan turbid solution obtained by centrifugal separation of a high-speed centrifuge with a rotating speed of 10000rpm is used to obtain a chitosan precipitate, and the precipitate is washed with distilled water until the pH of the washing solution is 7. Obtain chitosan gel;

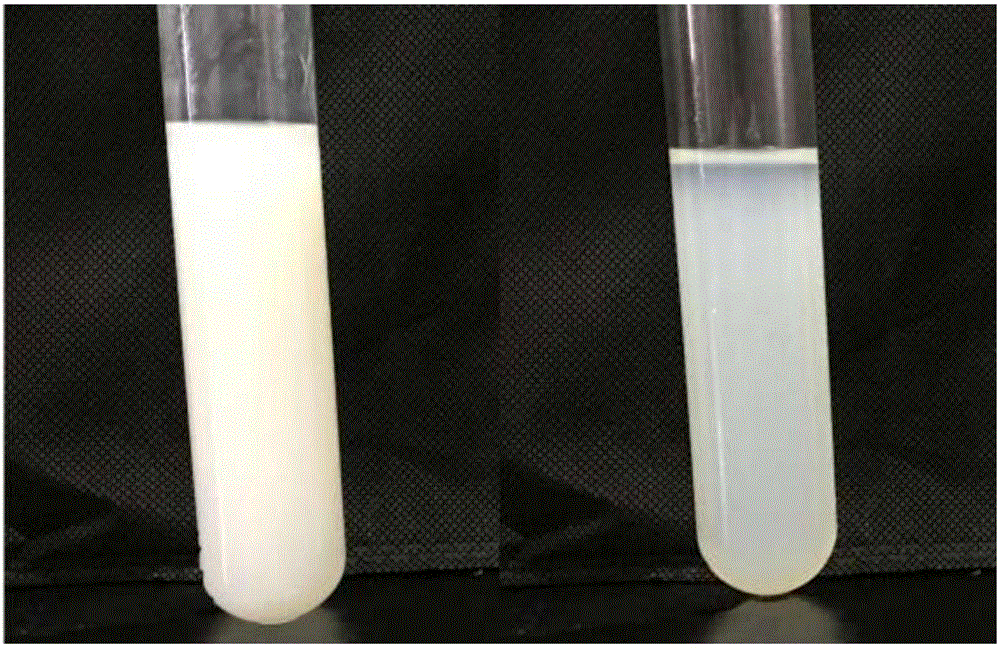

[0049] The particle size of the chitosan condensate cloudy solution that adopts laser particle size analyzer test to obtain, i...

Embodiment 3

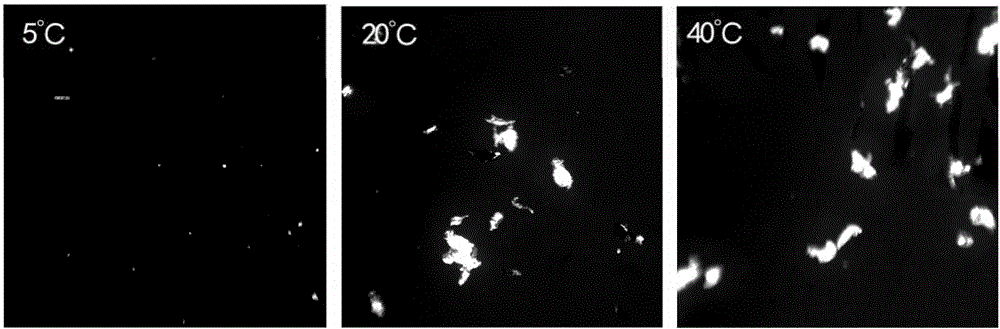

[0053] Using 0.5% acetic acid aqueous solution as a solvent, deacetylation degree ≥ 90%, and chitosan with a viscosity-average molecular weight of 50,000 as a raw material, stirring and dissolving to obtain a chitosan solution with a mass percentage concentration of 3%, while using a rotating speed of The chitosan solution that the homogenizer of 30000rpm stirs makes, while adding concentration dropwise is the sodium hydroxide aqueous solution of 3g / L, until the pH value of solution is 8, stops adding sodium hydroxide aqueous solution, obtains the turbidity of chitosan solution; the chitosan turbid solution obtained by centrifugation of a high-speed centrifuge with a rotating speed of 10000rpm is used to obtain a chitosan precipitate, and the precipitate is washed with distilled water until the pH of the washing solution is 7 to obtain a chitosan gel body; using a mass percent concentration of 3% glycerol aqueous solution as a solvent, and then using a rotating speed of 30000rp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com