Preparation method and application of nano material CuS/Ni

A technology of nanomaterials and application methods, which is applied in the field of preparation and application of nanomaterial CuS/Ni, can solve the problems of low cost, non-regular shape of copper sulfide particles, weak controllability, etc., and achieve low cost and increased The ability to capture electrons, the effect of strong controllability of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

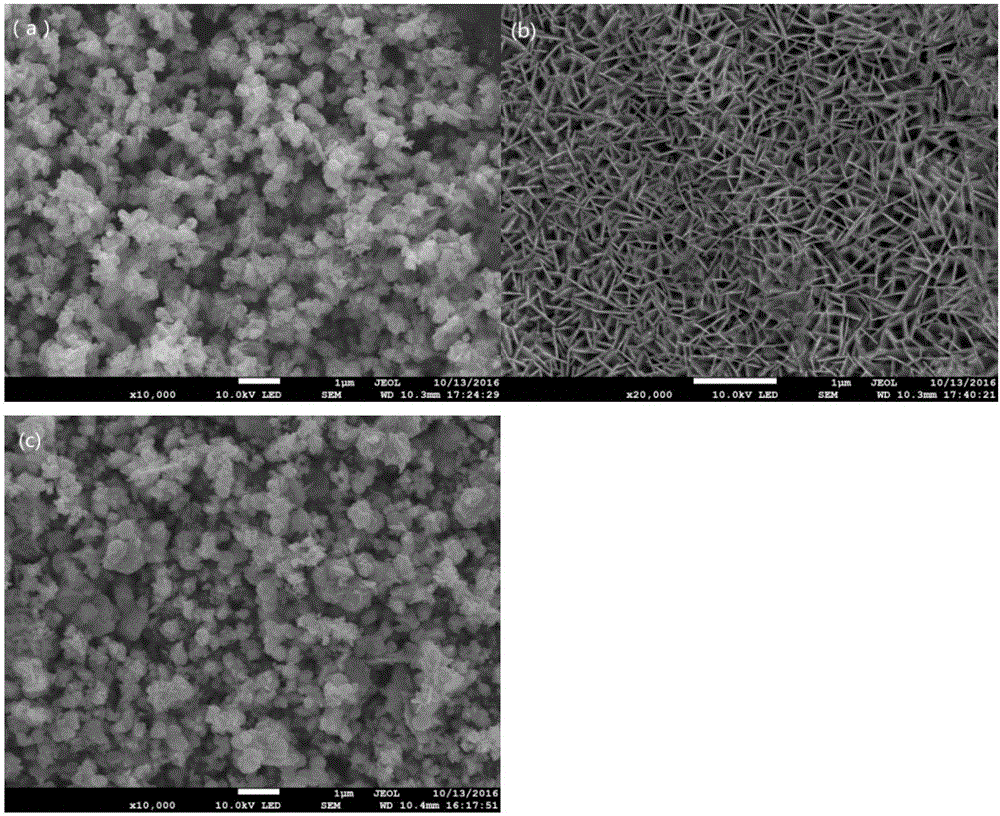

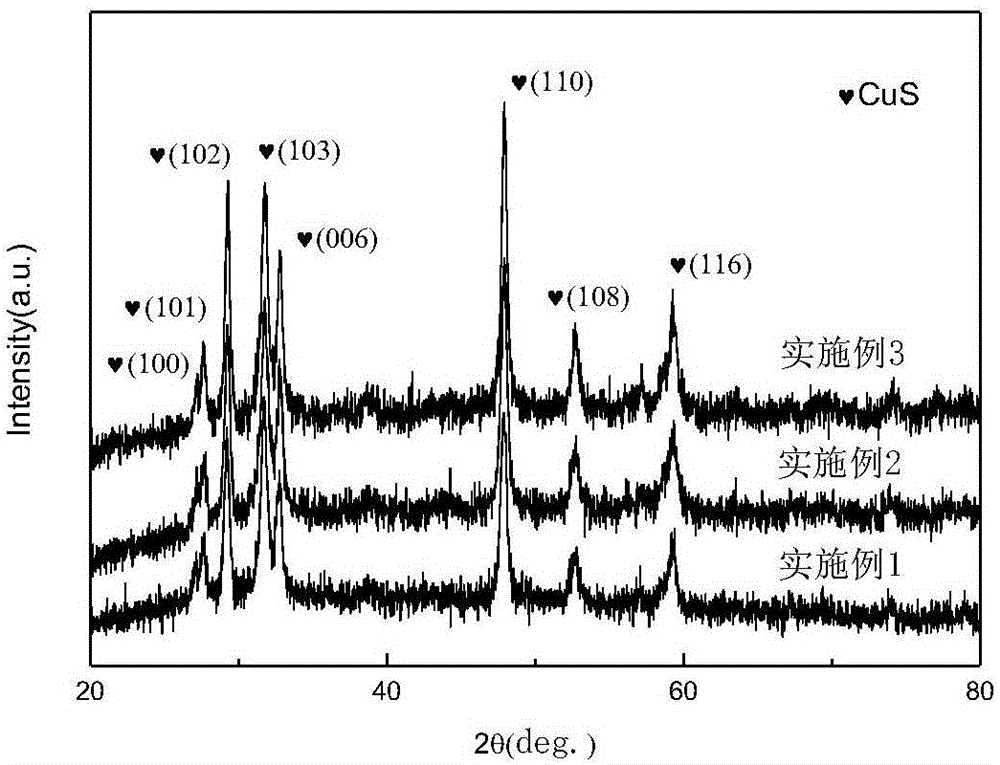

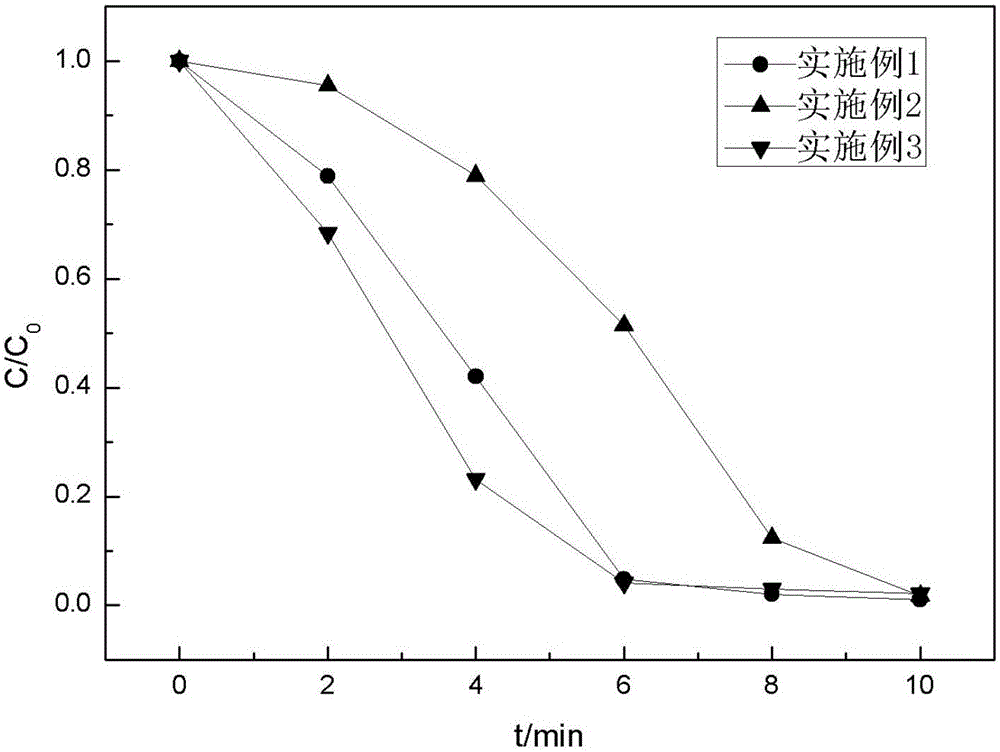

Embodiment 1

[0021] Copper / nickel sulfide catalysts with nanoscale cluster structure were prepared by chemical dealloying method on Ti-Cu-Ni amorphous alloy strips. Its preparation steps are as follows:

[0022] Step 1. Prepare Ti-Cu-Ni amorphous alloy strip according to the following atomic percentage content: the content of Ti is 50%, the content of Cu is 45%, and the content of Ni is 5%. Crystal alloy strips.

[0023] Step 2, the thickness obtained in step 1 is 20μm, the width is 6mm Ti 50 Cu 45 Ni 5 Amorphous alloy strips were cut into strips with a length of 2 cm; the strips were ultrasonically cleaned in absolute ethanol for 10 minutes, then cleaned with deionized water, then placed in air, and the alloy strips were dried for later use;

[0024] Step 3, the Ti prepared in step 2 50 Cu 45 Ni 5 Weigh 0.2g of the amorphous alloy strip and place it in a closed container together with 27.5ml of sulfuric acid aqueous solution with a molar concentration of 15M, and put it in a 90°C d...

Embodiment 2

[0032] Copper / nickel sulfide catalysts with nanoscale cluster structure were prepared by chemical dealloying method on Ti-Cu-Ni amorphous alloy strips. Its preparation steps are as follows:

[0033]Step 1. Prepare Ti-Cu-Ni amorphous alloy strip according to the following atomic percentage content: the content of Ti is 50%, the content of Cu is 42%, and the content of Ni is 8%. Crystal alloy strips.

[0034] Step 2, the thickness obtained in step 1 is 20 μm, the Ti with a width of 6 mm 50 Cu 42 Ni 8 Amorphous alloy strips were cut into strips with a length of 2 cm; the strips were ultrasonicated in absolute ethanol for 10 minutes, cleaned with deionized water, then placed in air, and the alloy strips were dried for later use;

[0035] Step 3, the Ti prepared in step 2 50 Cu 42 Ni 8 Weigh 0.2g of the amorphous alloy strip and place it in a closed container together with 27.5ml of sulfuric acid aqueous solution with a molar concentration of 15M, and put it in a 90°C drying...

Embodiment 3

[0043] Copper / nickel sulfide catalysts with nanoscale cluster structure were prepared by chemical dealloying method on Ti-Cu-Ni amorphous alloy strips. Its preparation steps are as follows:

[0044] Step 1. Prepare Ti-Cu-Ni amorphous alloy strip according to the following atomic percentage content: the content of Ti is 50%, the content of Cu is 39%, and the content of Ni is 11%. Crystal alloy strips.

[0045] Step 2, the thickness obtained in step 1 is 20 μm, the Ti with a width of 6 mm 50 Cu 39 Ni 11 Amorphous alloy strips were cut into strips with a length of 2 cm; the strips were ultrasonically cleaned in absolute ethanol for 10 minutes, then cleaned with deionized water, then placed in air, and the alloy strips were dried for later use;

[0046] Step 3, the Ti prepared in step 2 50 Cu 39 Ni 11 Weigh 0.2g of the amorphous alloy strip and place it in a closed container together with 27.5ml of sulfuric acid aqueous solution with a molar concentration of 15M, and put it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length dimension | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com