High-temperature high-strength nuclear power nickel-based welding wire free of crack defects and preparation and application thereof

A high-strength, crack-free technology, applied in arc welding equipment, welding equipment, welding equipment, etc., can solve problems such as high temperature performance and crack resistance need to be further improved, nuclear island main equipment safety service hazards, etc., to achieve less defects, The effect of increased development requirements and high temperature strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

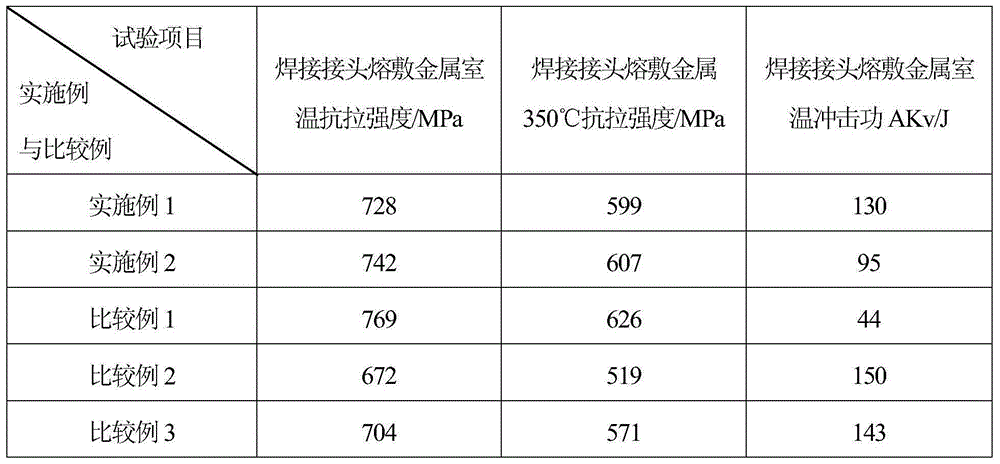

Examples

Embodiment Construction

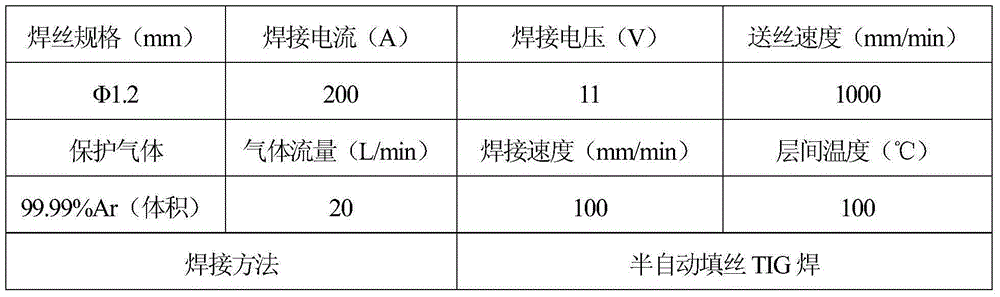

[0027] In a specific embodiment, the preparation method of the high-temperature, high-strength, crack-free nickel-based welding wire for nuclear power of the present invention is to prepare a master alloy steel ingot by vacuum smelting and electroslag remelting, and the master alloy steel ingot is forged into a section of 50 after being kept at 1130°C for 4 hours. ×50mm square billet, and then hot rolling at 1150°C for 1.5h to form a Φ6.5mm wire rod. The wire rod undergoes conventional multi-pass continuous cold drawing and intermediate hydrogen-filled annealing to make finished Φ1.2mm welding wire, and the tensile strength of the welding wire is 1000-1300MPa. In terms of weight percentage, the chemical composition of the nickel-based welding wire for nuclear power is as follows:

[0028] Cr: 28.0~31.0%, Fe: 7.0~11.0%, C: ≤0.04%, Mn: 0.7~0.9%, Si: 0.10~0.15%, Ti: 0.25~0.5%, Al: 0.15~0.4%, Al+ Ti: 0.4~0.8%, Mo: 2.0~4.0%, Nb: 1.5~2.5%, S:<0.005%, P:<0.005%, O≤0.005%, H≤2ppm, N≤...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com