Device and method for peeling graphene slurry by utilizing fluid accelerated stirring

A technology for exfoliating graphene and fluids, applied in the field of graphene, can solve problems such as inability to stably disperse, be difficult to open, and difficult to mass-produce, and achieve the effects of increasing exfoliation efficiency, increasing shearing effect, and high exfoliation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) Dissolving sodium dodecyl sulfonate into pure water, the concentration of the sodium dodecyl sulfonate aqueous solution is 0.5mg / L;

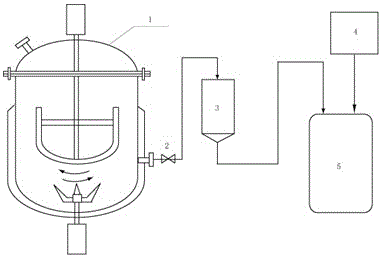

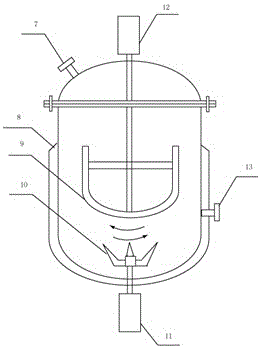

[0044] (2) Add the graphite powder and the above-mentioned surfactant solution into the aforementioned reaction kettle 1, close the valve 2, and run the U-shaped stirring paddle 9 and the turbine 10 in the reaction kettle 1. The rotation direction of the two is opposite, and the speed is 8000r / min , the graphite powder is exfoliated by the strong shear force generated by the accelerated stirring of the fluid, the weight ratio of the graphite powder to the surfactant is 1:10, and the exfoliation time is 5 hours to obtain a slurry mixed with graphene and graphite particles;

[0045] (3) Open the valve 2, filter the obtained graphene slurry in a slurry filter, remove the unstripped graphite powder, and obtain the graphene slurry;

[0046] (4) Dissolving the shell material in water, the concentration of the aqueous solution of the shell m...

Embodiment 2

[0048] (1) Sodium dodecylbenzenesulfonate was dissolved in pure water, and the concentration of the sodium dodecylbenzenesulfonate aqueous solution was 2 mg / L;

[0049] (2) Add the graphite powder and the above-mentioned surfactant solution into the aforementioned reaction kettle 1, close the valve 2, and run the U-shaped stirring paddle 9 and the turbine 10 in the reaction kettle 1. The rotation direction of the two is opposite, and the speed is 5000r / min , the graphite powder is exfoliated by the strong shear force generated by the accelerated stirring of the fluid, the weight ratio of the graphite powder to the surfactant is 1:1, and the exfoliation time is 5 hours to obtain a slurry mixed with graphene and graphite particles;

[0050] (3) Open the valve 2, filter the obtained graphene slurry in a slurry filter, remove the unstripped graphite powder, and obtain the graphene slurry;

[0051] (4) Dissolving the shell material in water, the concentration of the aqueous solutio...

Embodiment 3

[0053] (1) Sodium dodecylbenzenesulfonate was dissolved in pure water, and the concentration of the sodium dodecylbenzenesulfonate aqueous solution was 5 mg / L;

[0054] (2) Add the graphite powder and the above-mentioned surfactant solution into the aforementioned reaction kettle 1, close the valve 2, and run the U-shaped stirring paddle 9 and the turbine 10 in the reaction kettle 1. The rotation direction of the two is opposite, and the speed is 8000r / min , the graphite powder is exfoliated by the strong shear force generated by the accelerated stirring of the fluid, the weight ratio of the graphite powder to the surfactant is 1:0.2, and the exfoliation time is 5 hours to obtain a slurry mixed with graphene and graphite particles;

[0055] (3) Open the valve 2, filter the obtained graphene slurry in a slurry filter, remove the unstripped graphite powder, and obtain the graphene slurry;

[0056] (4) Dissolving the shell material in water, the concentration of the shell materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com