Sea urchin-shaped niobium pentoxide electrode material and preparation method thereof

A technology of niobium pentoxide and electrode materials, which is applied in chemical instruments and methods, inorganic chemistry, niobium compounds, etc., can solve the problems of irregular shape and poor dispersion of sea urchin-like niobium pentoxide microspheres, and achieve excellent electrochemical performance Performance, good dispersibility, uniform and regular shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Step 1), niobium pentachloride was dissolved in deionized water, stirred for 2 hours, wherein the concentration of niobium ions was 0.032mol / L;

[0034] Step 2), hydrofluoric acid is added dropwise to the above solution, wherein the molar ratio of niobium pentachloride to hydrofluoric acid is 1:1, and stirring is continued for 6 hours;

[0035] Step 3), transfer the solution obtained in step 2) to a stainless steel reaction kettle lined with polytetrafluoroethylene, place it in a constant temperature drying oven, and heat and react at 170°C for 24 hours;

[0036] Step 4), the reaction precipitate obtained in step 3) was washed several times with ethanol and deionized water, respectively, until the solution was neutral, and then dried in a vacuum oven at a temperature of 80°C;

[0037] Step 5), the powder obtained in step 4) is placed in a tube furnace, and roasted at 550° C. for 2 hours to obtain the sea urchin-shaped niobium pentoxide.

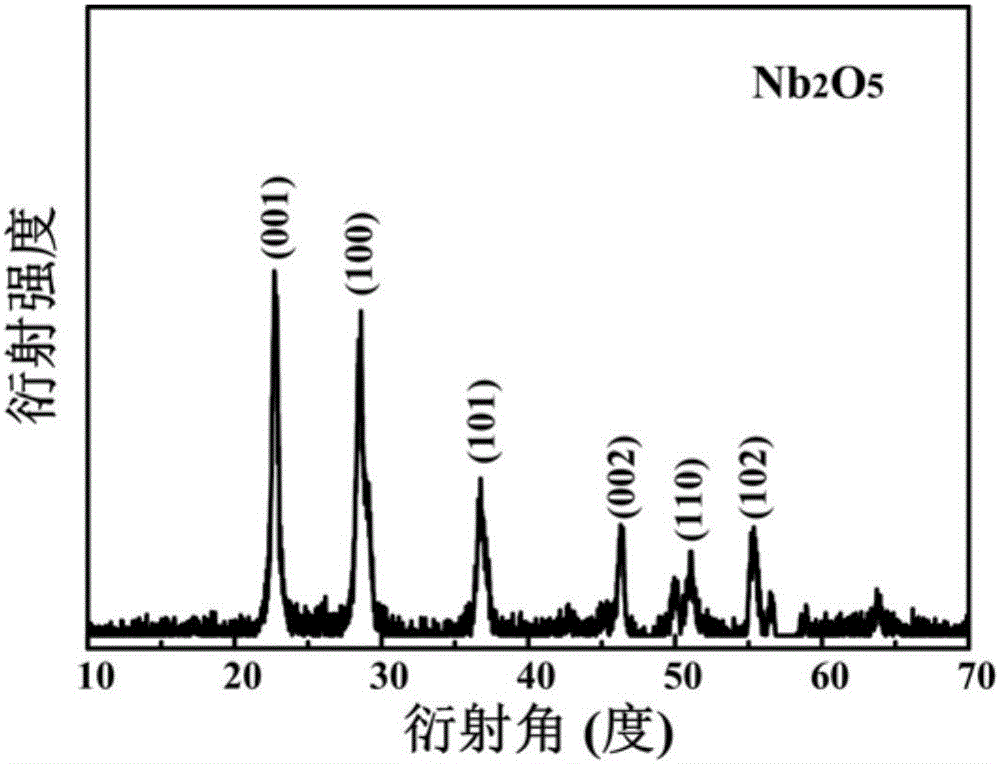

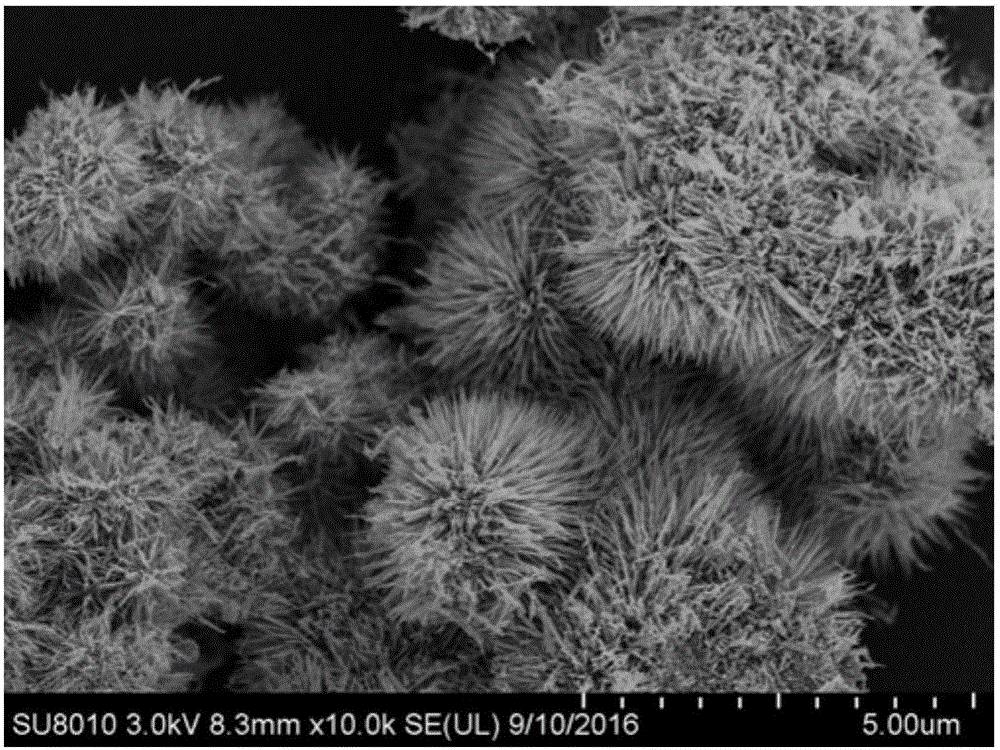

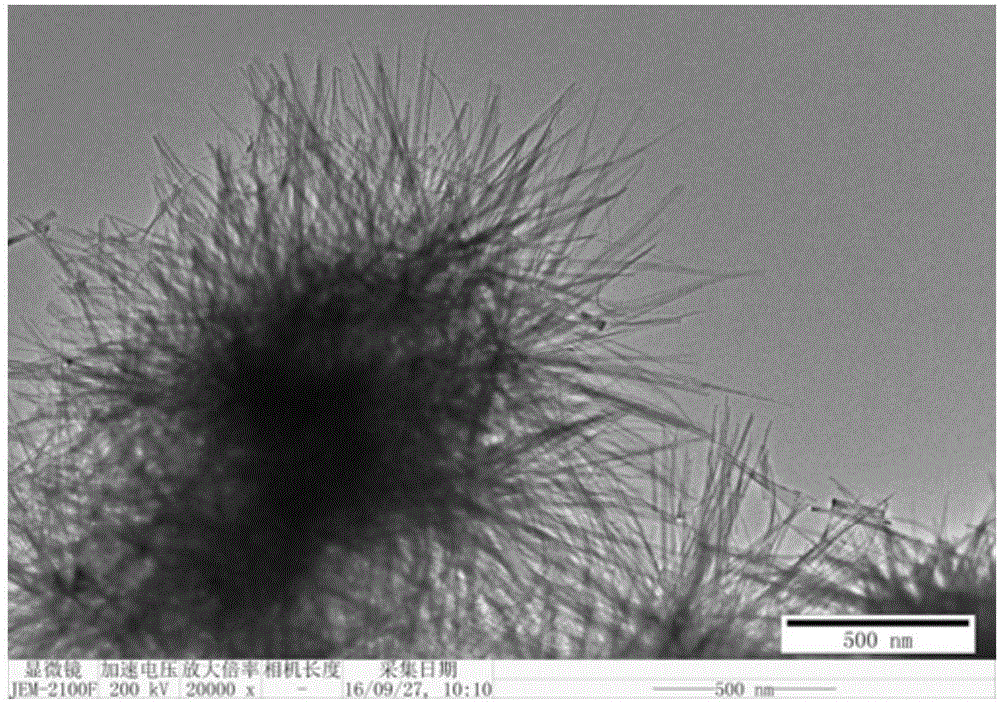

[0038] like figure 1 As shown...

Embodiment 2

[0040] Step 1), niobium pentachloride was dissolved in deionized water, stirred for 12 hours, wherein the concentration of niobium ions was 0.030mol / L;

[0041] Step 2), hydrofluoric acid is added dropwise to the above solution, wherein the molar ratio of niobium pentachloride to hydrofluoric acid is 1:0.8, and stirring is continued for 15 hours;

[0042] Step 3), the solution obtained in step 2) was transferred to a stainless steel reaction kettle lined with polytetrafluoroethylene, placed in a constant temperature drying oven, and heated and reacted at 165°C for 30 hours;

[0043] Step 4), the reaction precipitate obtained in step 3) was washed several times with ethanol and deionized water, until the solution was neutral, and then dried in a vacuum oven at a temperature of 110°C;

[0044] Step 5), the powder obtained in step 4) is placed in a tube furnace, and roasted at 500° C. for 3 hours to obtain the sea urchin-shaped niobium pentoxide.

Embodiment 3

[0046] Step 1), dissolving ammonium niobium pentachloride in deionized water, stirring for 0.1 hour, wherein the concentration of niobium ions is 0.034mol / L;

[0047] Step 2), adding hydrofluoric acid dropwise to the above solution, wherein the molar ratio of niobium pentachloride to hydrofluoric acid is 1:1.2, and continue stirring for 12 hours;

[0048] Step 3), transfer the solution obtained in step 2) to a stainless steel reaction kettle lined with polytetrafluoroethylene, place it in a constant temperature drying oven, and heat and react at 172°C for 20 hours;

[0049] Step 4), the reaction precipitate obtained in step 3) was washed several times with ethanol and deionized water, respectively, until the solution was neutral, and then dried in a vacuum oven at a temperature of 100°C;

[0050] Step 5), the powder obtained in step 4) is placed in a tube furnace, and roasted at 580° C. for 1.8 hours to obtain the sea urchin-shaped niobium pentoxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com