Manufacturing method of high purity manganese sulphate from manganese sulphate waste liquid

A manganese sulfate, high-purity technology, applied in manganese sulfate, chemical instruments and methods, copper sulfide, etc., can solve problems such as environmental pollution and huge treatment costs, and achieve the effect of preventing secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

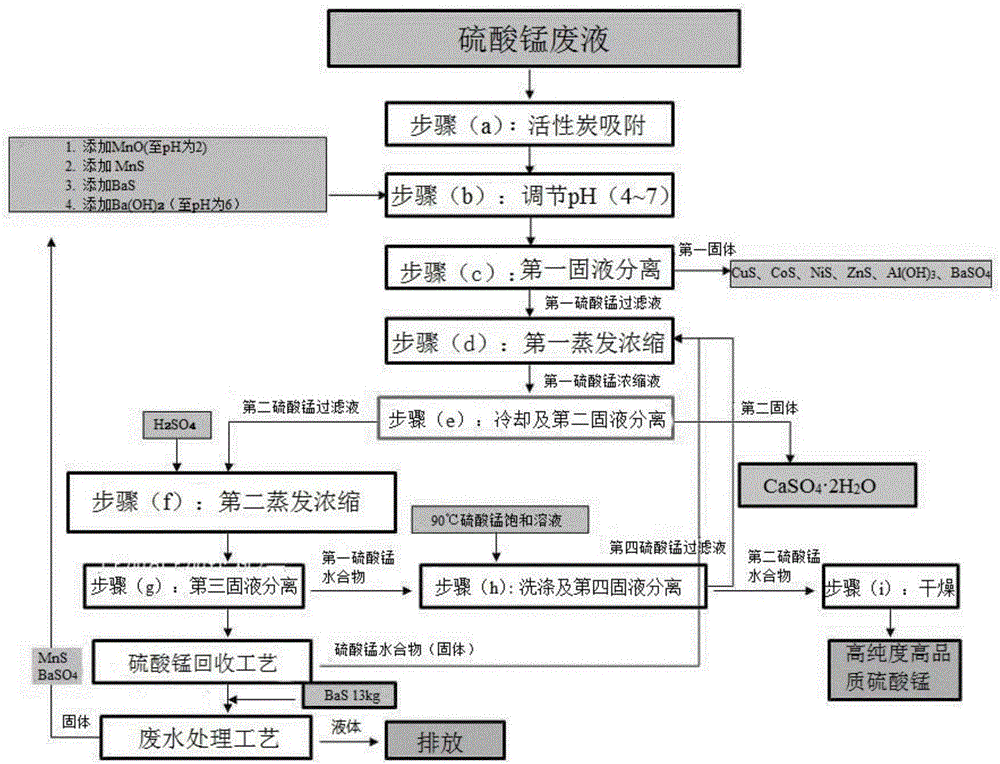

Method used

Image

Examples

Embodiment

[0078] 1. Preparation of high-purity manganese sulfate

[0079] 1) Preparation of manganese sulfate waste liquid for removing organic matter

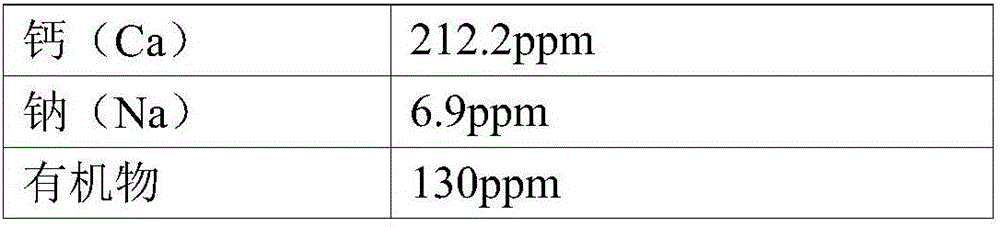

[0080] First, 1 ton of manganese sulfate waste liquid obtained by recycling lithium ion secondary batteries was prepared. The prepared manganese sulfate waste liquid has a pH of 1 and its composition is shown in Table 1. 1 ton of the above-mentioned manganese sulfate waste liquid is passed through an activated carbon adsorption tower to remove organic matter. As shown in Table 1, the organic matter contained in 1 ton of the above-mentioned manganese sulfate waste liquid is 130 ppm in total. After passing 1 ton of manganese sulfate waste liquid through the above-mentioned activated carbon adsorption tower, the total organic carbon (TOC) was measured, and it was found that the content of organic matter was below 20 ppm.

[0081] Table 1

[0082]

[0083]

[0084] 2) Removal of copper (Cu), aluminum (Al), cobalt (Co), nickel (Ni)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com