Polymer elastic particle reservoir protection agent and its preparation method and application

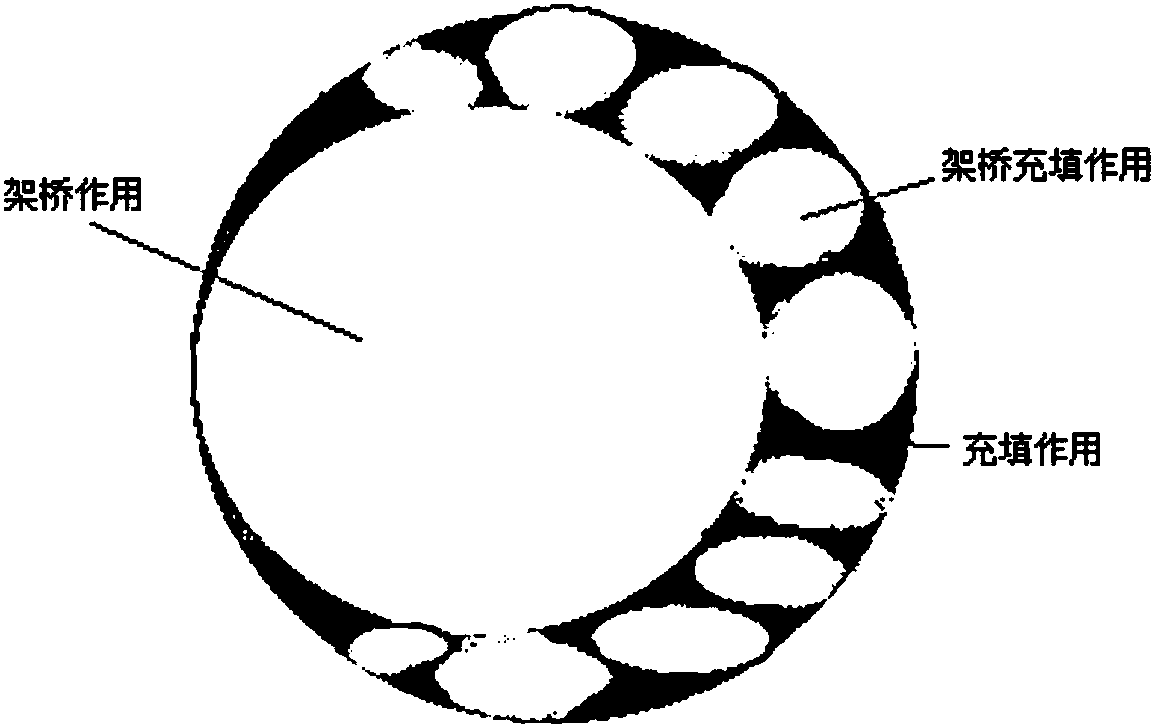

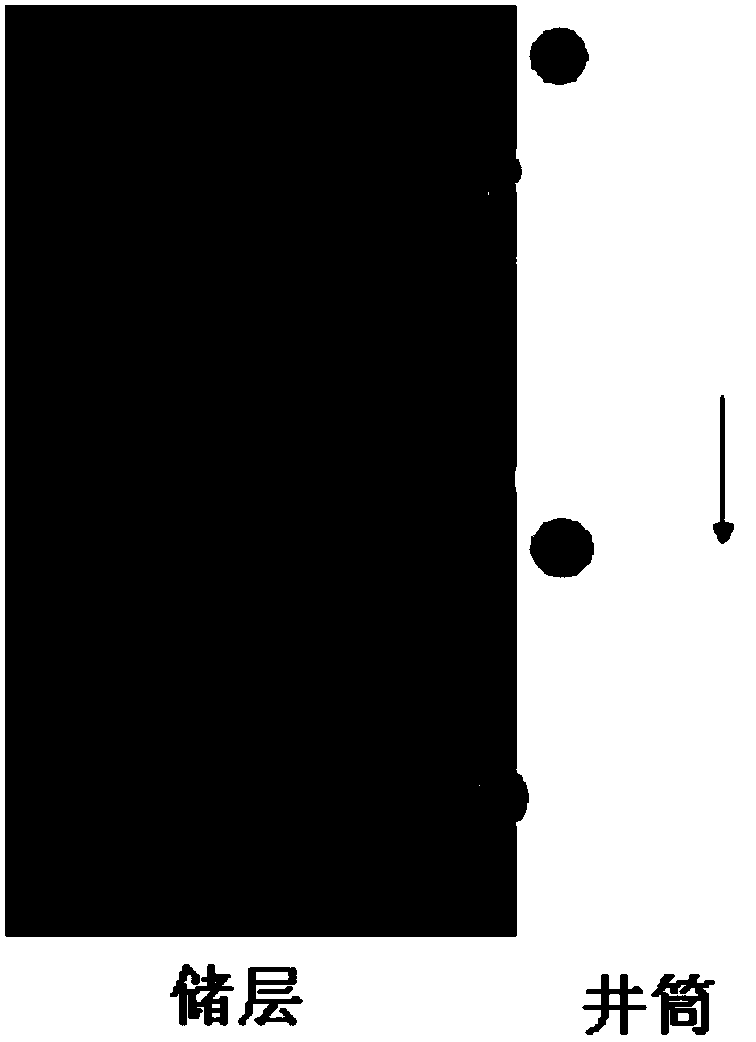

A reservoir protective agent and reservoir technology are applied in the field of reservoir protective agent intermediate products, reservoir protective agent and its preparation, and drilling fluid fields, which can solve the problems of poor plugging effect and unsatisfactory plugging effect, and achieve Excellent reservoir protection performance, improving reservoir protection ability and overcoming poor adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] In the second aspect, the present invention provides a method for preparing the intermediate product of the reservoir protective agent, the method comprising: mixing acrylamide, cationic monomer, crosslinking agent, toughening material and water, and adding to the resulting mixture The initiator reacts, and then the reaction product is dried and crushed.

[0030] Preferably, the method of mixing acrylamide, cationic monomer, crosslinking agent, toughening material, and water includes: (1) adding acrylamide, cationic monomer and crosslinking agent to water to dissolve, and stirring uniformly; (2) (1) Add the toughening material to the mixture of step (1) and stir it evenly; (3) stir the mixture of step (2) under a protective atmosphere. Wherein, the protective atmosphere may be nitrogen and / or inert gas, and the stirring time in step (3) may be 20-30 min.

[0031] Preferably, the reaction conditions include: a temperature of 30-60° C. and a time of 3-5 h. After the reaction...

Embodiment 1

[0049] Add 20kg of acrylamide, 4kg of dimethyldiallylammonium chloride and 0.01kg of N,N'-methylenebisacrylamide into 67.96kg of water to fully dissolve, then add 8kg of bentonite and stir well. The above reaction liquid was added to a reactor equipped with a stirrer, condenser, and thermometer, protected by nitrogen, stirred for 20 minutes, then adjusted the temperature to 60°C, added 0.03kg of ammonium persulfate, stopped nitrogen flow and stirring, and reacted 3h; Take out the reaction product, dry it at 105°C for 15h, and pulverize to obtain a granular intermediate product of the reservoir protective agent.

[0050] Take 10kg of intermediate product and 5kg of sodium carbonate, add 79.95kg of water and stir continuously for 10h, then add 5kg of sodium chloride and 0.05kg of octadecyltrimethylammonium chloride, continue to stir for 0.5h to obtain polymer elastic particle reservoir protection Agent.

[0051] The drilling fluid was prepared according to the following formula: 2% ...

Embodiment 2

[0053] Add 25kg of acrylamide, 5kg of methacryloyloxyethyl trimethylammonium chloride and 0.02kg of glutaraldehyde into 59.93kg of water to fully dissolve, then add 10kg of starch and stir well. The above reaction liquid was added to a reactor equipped with a stirrer, condenser, and thermometer, protected by nitrogen, stirred for 30 minutes, then adjusted the temperature to 50°C, added 0.05kg potassium persulfate, stopped nitrogen flow and stirring, and reacted 4h: Take out the reaction product, dry it at 110°C for 12h, and pulverize to obtain a granular intermediate product of the reservoir protective agent.

[0054] Take 20 kg of the intermediate product, 3 kg of potassium hydroxide and 0.3 kg of cetyl pyridinium chloride, add 69.7 kg of water and continue stirring for 10 hours, then add 7 kg of potassium chloride and continue stirring for 1 hour to obtain a polymer elastic particle reservoir protective agent.

[0055] The drilling fluid was prepared according to the method of Ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com