A kind of recycled plastic particles and its preparation method

A technology for recycled plastic particles and plastics, which is applied in the field of recycled plastic particles and their preparation, can solve the problems of limited scope and field of reuse, lack of toughness, low gloss, etc., and achieves increased interface compatibility and improved flame retardancy. Excellent performance and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Crushing waste plastic raw materials; using detergent to wash, and then rinsing with water; using electromagnetic iron remover to remove iron; using an extruder to heat, extrude and cool plastic raw materials to obtain recycled plastics; the recycled plastics include The following components: acrylonitrile-butadiene-styrene copolymer (ABS), polyethylene terephthalate (PET), polycarbonate (PC), polystyrene (PS), polypropylene (PP) ).

[0028] The recycled plastic is modified by a compatibilizer, a toughening agent, and a chain extender to obtain a modified recycled plastic; wherein, the specific process of modification is to put the recycled plastic into a compatibilizer, a toughening agent After mixing with the chain extender, knead in a continuous mixer for 15 minutes; the quality of the compatibilizer, toughening agent, and chain extender is respectively 3.2%, 2.5%, and 0.1% of the recycled plastic.

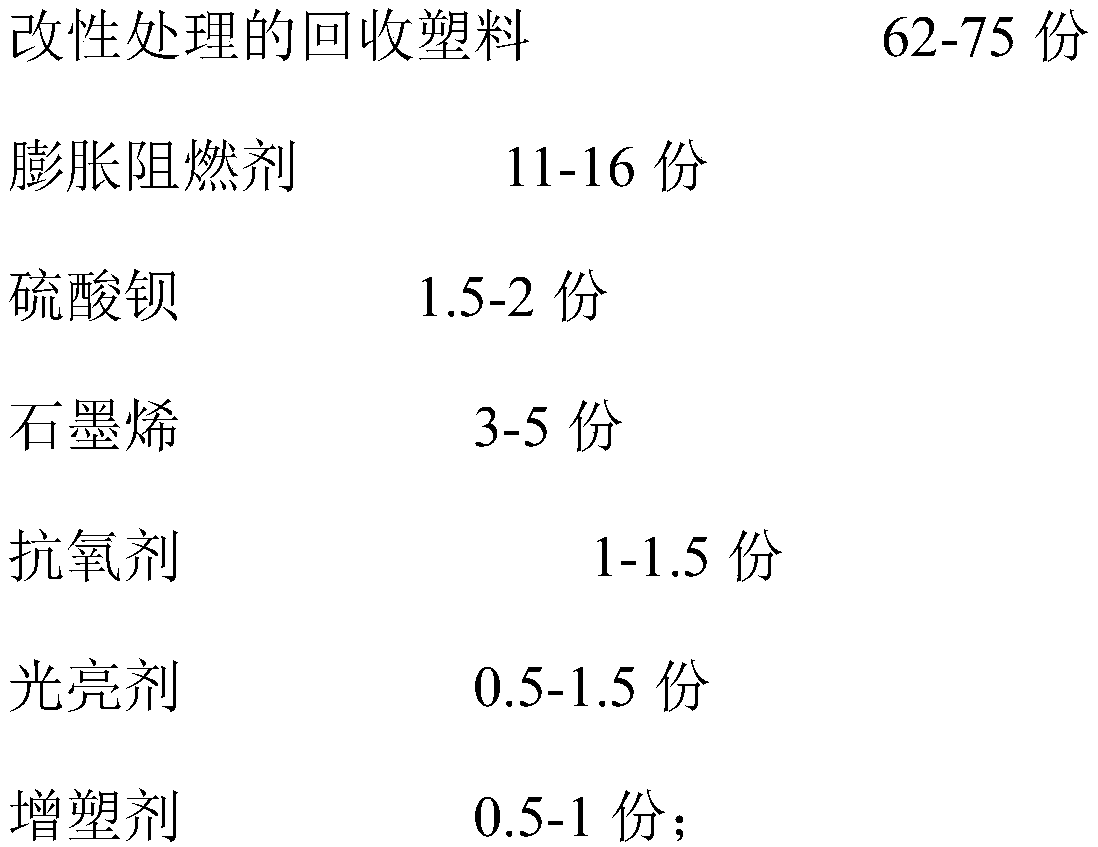

[0029] Ingredients according to the following parts by weight:

...

Embodiment 2

[0037] Crushing waste plastic raw materials; using detergent for washing, followed by rinsing with water; using electromagnetic iron remover for iron removal treatment; using extruder to heat, extrude and cool plastic raw materials to obtain recycled plastics; the recycled plastics include The following components: polyethylene terephthalate (PET) and polycarbonate (PC).

[0038] The recycled plastic is modified by a compatibilizer, a toughening agent, and a chain extender to obtain a modified recycled plastic; wherein, the specific process of modification is to put the recycled plastic into a compatibilizer, a toughening agent After mixing with the chain extender, knead in a continuous mixer for 20 minutes; the quality of the compatibilizer, toughening agent, and chain extender are respectively 5.5%, 3%, and 0.3% of the recycled plastic.

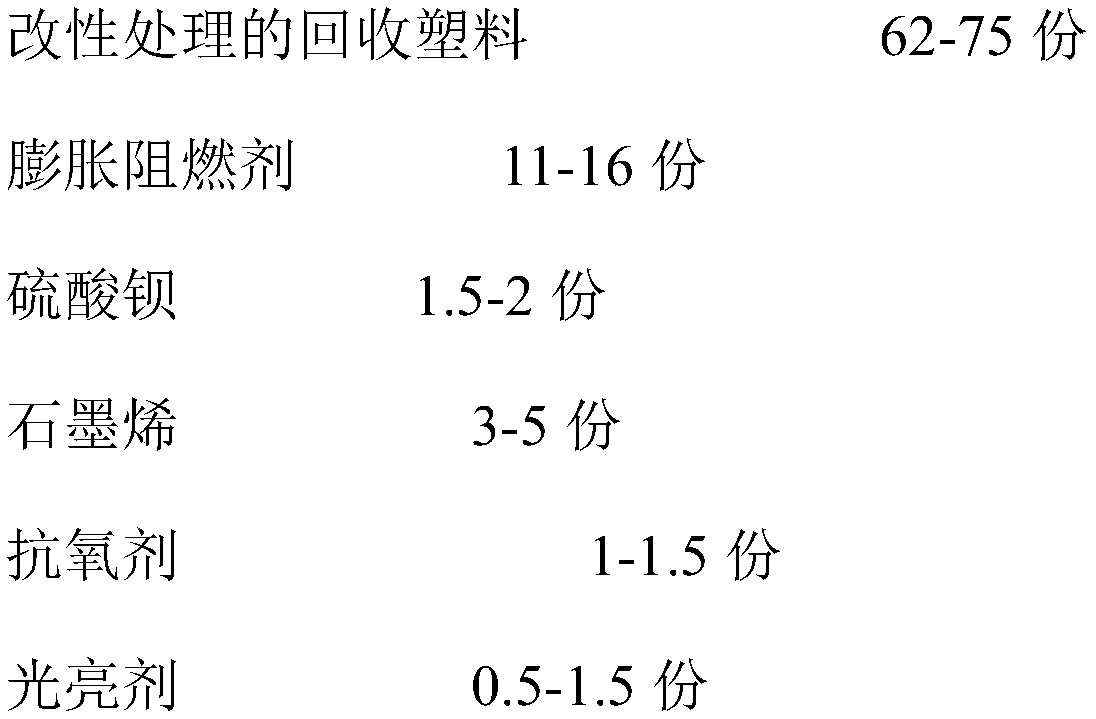

[0039] Ingredients according to the following parts by weight:

[0040]

[0041]

[0042] Stir all the above-mentioned ingredients ...

Embodiment 3

[0048] Crushing waste plastic raw materials; using detergent to wash, and then rinsing with water; using electromagnetic iron remover to remove iron; using an extruder to heat, extrude and cool plastic raw materials to obtain recycled plastics; the recycled plastics include The following components: acrylonitrile-butadiene-styrene copolymer (ABS), polyethylene terephthalate (PET), polycarbonate (PC), polystyrene (PS), polypropylene (PP) ), or have some of the above-mentioned components.

[0049] The recycled plastic is modified by a compatibilizer, a toughening agent, and a chain extender to obtain a modified recycled plastic; wherein, the specific process of modification is to put the recycled plastic into a compatibilizer, a toughening agent After mixing with the chain extender, knead in a continuous mixer for 30 minutes; the quality of the compatibilizer, toughening agent, and chain extender are respectively 8.1%, 3.2%, and 0.5% of the recycled plastic.

[0050] Ingredient...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com