Preparation method of conductive paste

A conductive paste, the technology of the second step, applied in the field of preparation of non-metallic conductive paste, can solve the problems of low-temperature storage of conductive paste, difficult to clean, toxic and harmful substances, etc., and achieve the effects of not easy to deteriorate, easy to clean, and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

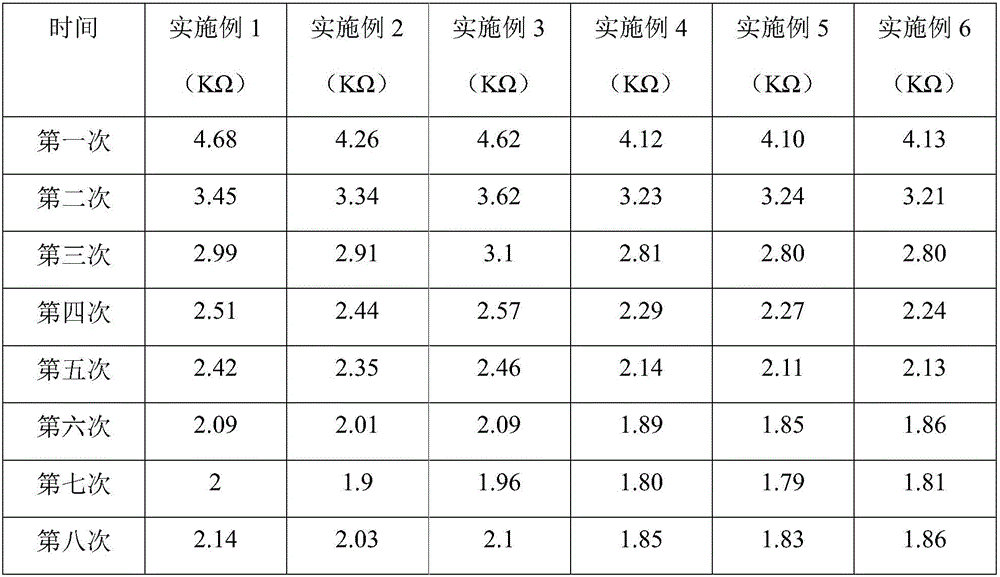

Examples

Embodiment 1

[0026] A preparation method of conductive paste, comprising the steps of:

[0027] Step 1, take 5 parts by weight of glycerin and 15 parts by weight of sodium chloride and dissolve them in 50 parts by weight of water, and adjust the pH value of the solution to 5-6 with hydrochloric acid;

[0028] Step 2: Take 28.5 parts by weight of chitosan and add it to the solution in Step 1, then heat it in a water bath to 95°C while stirring, keep stirring at this temperature for 30min, and the stirring speed is 1000r / min;

[0029] Step 3: Add 1.5 parts by weight of carrageenan to Step 2, stir until it is completely dissolved, and then start to cool down at a cooling rate of 5°C / min, drop the temperature to 70°C, and then heat and stir for 3 minutes;

[0030] Step 4, cooling the product obtained in Step 3 to room temperature to obtain the conductive paste.

Embodiment 2

[0032] A preparation method of conductive paste, comprising the steps of:

[0033] Step 1. Dissolve 8.5 parts by weight of glycerin and 10 parts by weight of sodium chloride with 50 parts by weight of water, and adjust the pH value of the solution to 5-6 with hydrochloric acid;

[0034] Step 2: Take 29.5 parts by weight of carboxymethyl cellulose and add it to the solution in Step 1, then heat it in a water bath to 100°C while stirring, keep stirring at this temperature for 45 minutes, and the stirring speed is 800r / min;

[0035] Step 3: Add 2 parts by weight of konjac gum to step 2, stir until it is completely dissolved, and start to cool down at a cooling rate of 5°C / min, then cool down to 60°C, then heat and stir for 6 minutes;

[0036] Step 4, cooling the product obtained in Step 3 to room temperature to obtain the conductive paste.

Embodiment 3

[0038] A preparation method of conductive paste, comprising the steps of:

[0039] Step 1. Dissolve 10 parts by weight of glycerin and 11.5 parts by weight of sodium chloride with 50 parts by weight of water, and adjust the pH value of the solution to 5-6 with hydrochloric acid;

[0040] Step 2: Take 28 parts by weight of chitosan and add it to the solution in Step 1, then heat it in a water bath to 95°C while stirring, keep stirring at this temperature for 60min, and the stirring speed is 500r / min;

[0041] Step 3: Add 0.5 parts by weight of xanthan gum to step 2, stir until it is completely dissolved, and then start to cool down at a cooling rate of 5°C / min, drop the temperature to 65°C, and then heat and stir for 5 minutes;

[0042] Step 4, cooling the product obtained in Step 3 to room temperature to obtain the conductive paste.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com