Preparation method of highly dispersed superfine powder particles

A fine powder, high dispersion technology, applied in the field of powder particle preparation, can solve problems such as poor dispersion performance and easy adhesion, and achieve the effects of improving the quality of dry powder inhalants, increasing the inhalable dose, and improving the dispersibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

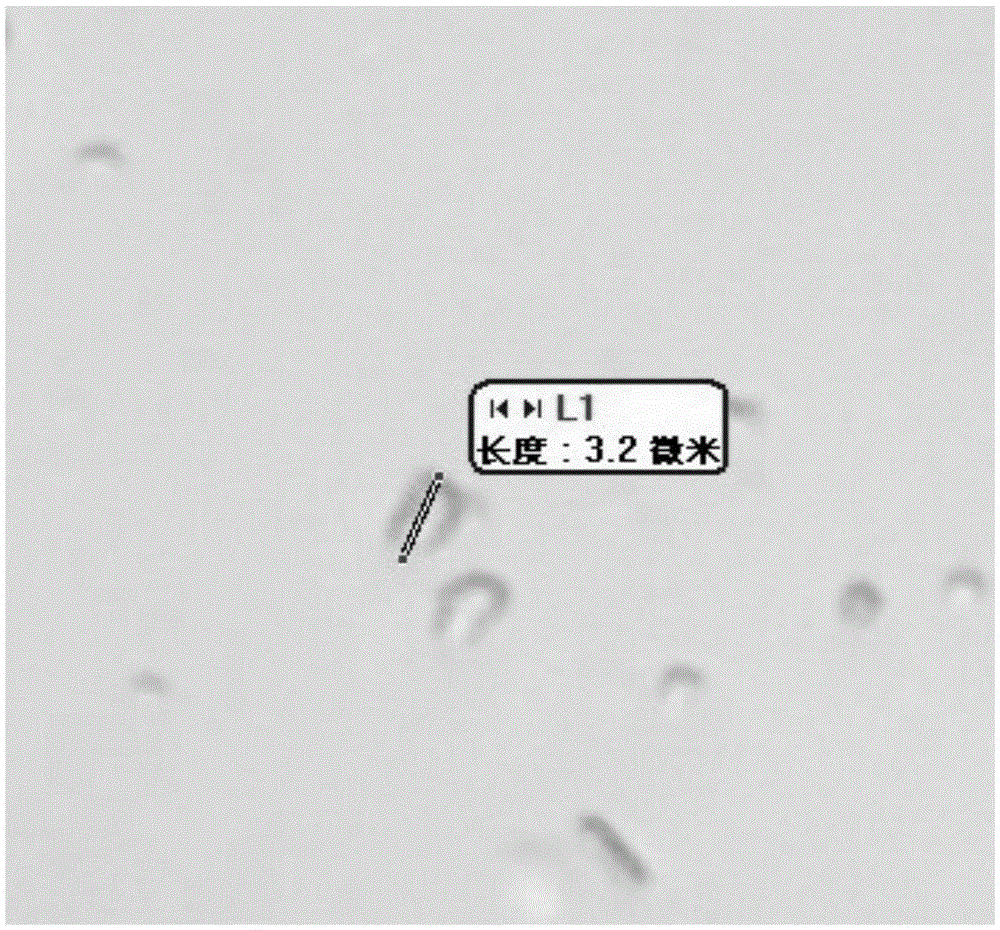

Image

Examples

Embodiment 1

[0067] The preparation of embodiment 1 salbutamol sulfate suspension type aerosol (vacuum drying method)

[0068] The active ingredient is the water-soluble active ingredient salbutamol sulfate, the additive is povidone k25, and the propellant is tetrafluoroethane (HFA134a). The preparation process of the aerosol sample is as follows:

[0069] (1) The pretreatment of active ingredient: get above-mentioned active ingredient salbutamol sulfate, through micronization process, obtain fine powder particle;

[0070] (2) Treatment of additives: take the above-mentioned additive povidone k25, add it to dehydrated ethanol, make completely dissolved, and obtain povidone k25 dehydrated alcohol solution;

[0071] (3) Preparation of the sample to be vacuum-dried: adding the water-soluble active ingredient salbutamol sulfate to the povidone k25 absolute ethanol solution, and dispersing evenly with a disperser to obtain a dispersion suspension;

[0072] (4) Sample drying treatment: the disp...

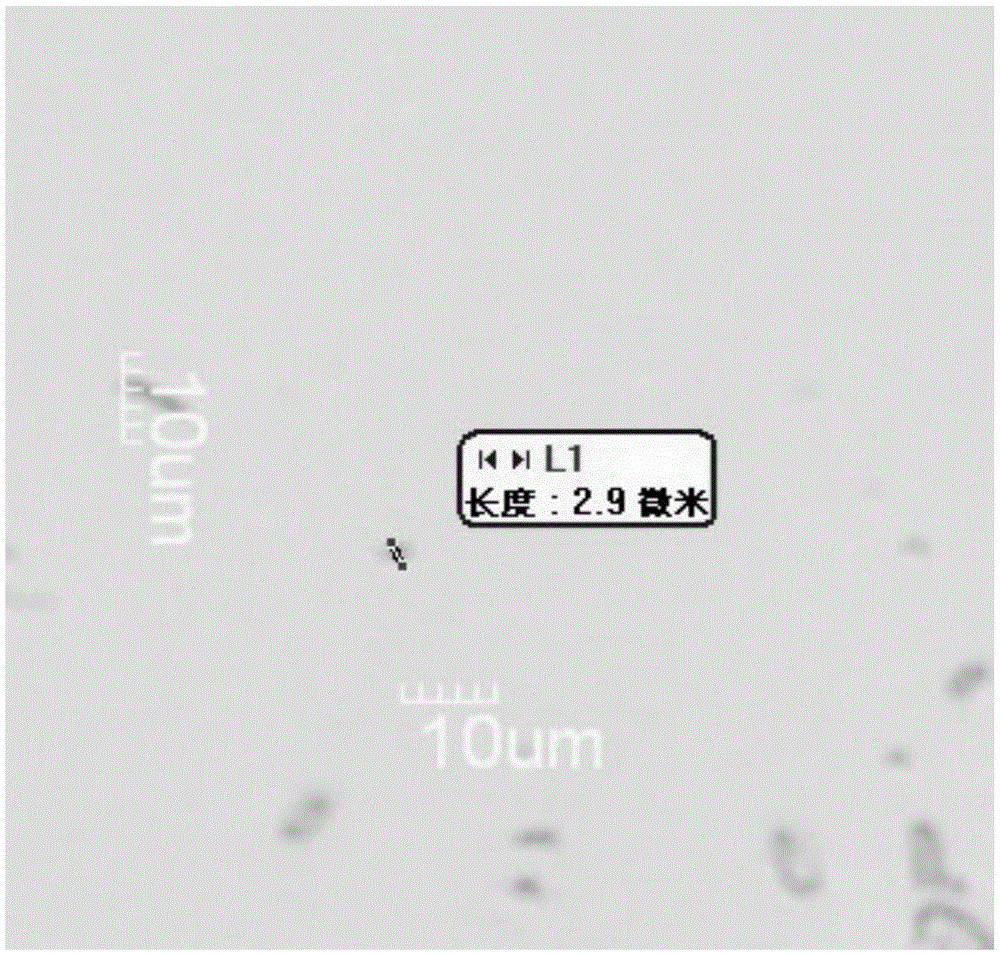

Embodiment 2

[0078] Embodiment 2: the preparation of salbutamol sulfate suspension type aerosol (spray drying method)

[0079] (1) The pretreatment of active ingredient: get above-mentioned active ingredient salbutamol sulfate, through micronization process, obtain fine powder particle;

[0080](2) Treatment of additives: take the above-mentioned additive povidone k25, add it to dehydrated ethanol, make completely dissolved, and obtain povidone k25 dehydrated alcohol solution;

[0081] (3) Preparation of the vacuum-dried sample: the water-soluble active ingredient salbutamol sulfate is added to the povidone k25 absolute ethanol solution, and the disperser is used to disperse evenly to obtain a dispersion suspension;

[0082] (4) Sample spray drying treatment: the dispersion suspension obtained above is subjected to spray drying treatment to obtain dry fine powder particles;

[0083] (5) Sample filling: the active ingredient salbutamol sulfate and the fine powder particles of the above-men...

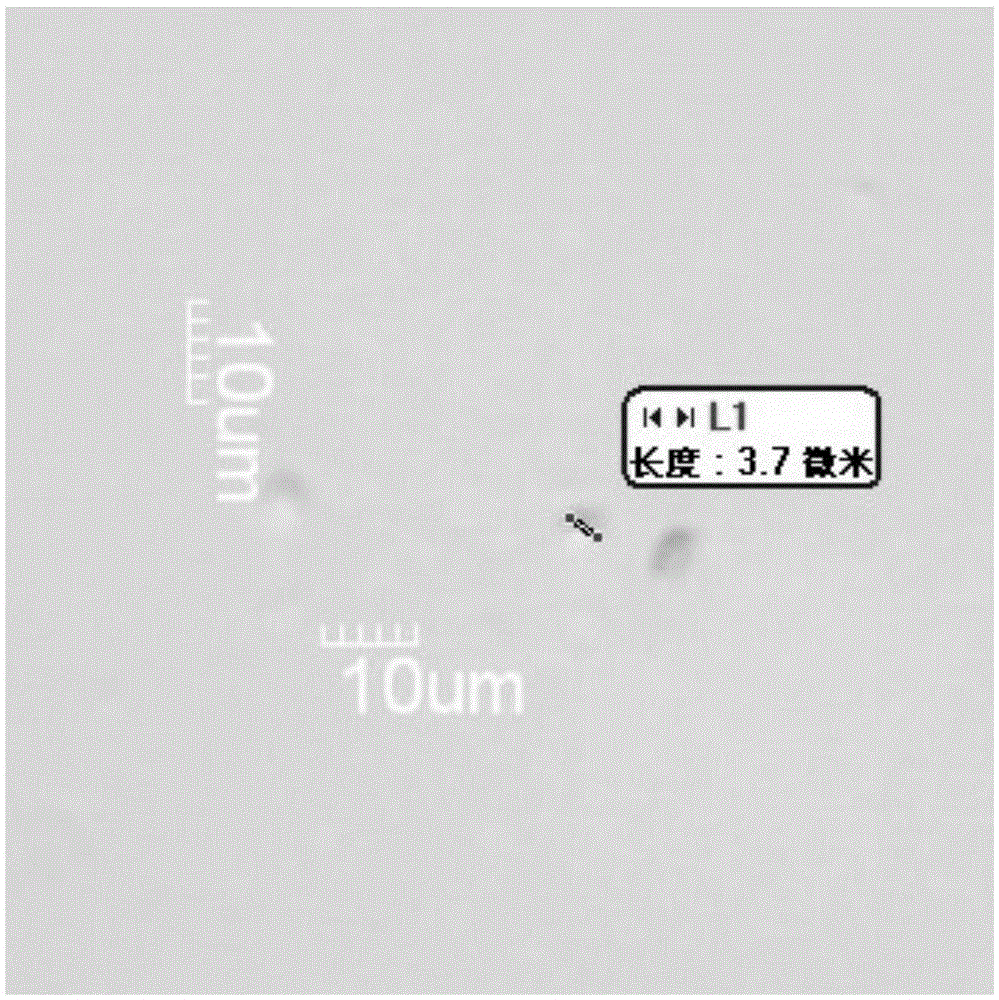

Embodiment 3

[0085] The preparation of embodiment 3 ribavirin suspension type aerosol (vacuum drying method)

[0086] The drug active ingredient is replaced by water-soluble ribavirin, and the operation is carried out according to Example 1, and the relevant test results are shown in surface 2 .

[0087]

[0088]

[0089] surface 2

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com