Intelligent hydroxybutyl chitosan hydrogel stent based on 3D printing technology and preparation method thereof

A technology for printing hydroxybutyl chitosan water and hydroxybutyl chitosan, which is used in medical science, prosthesis, additive processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Take hydroxybutyl chitosan with a hydroxybutyl substitution degree of 1.8, dissolve it in pure water to form a sol of 8.0 mg / mL, load it in a 3D printing cylinder, and let it stand at 4°C for defoaming, and then Place it in a water bath at 30°C and raise the temperature for 15 minutes to make it undergo a gelation transition to obtain a hydrogel that can be used for 3D printing.

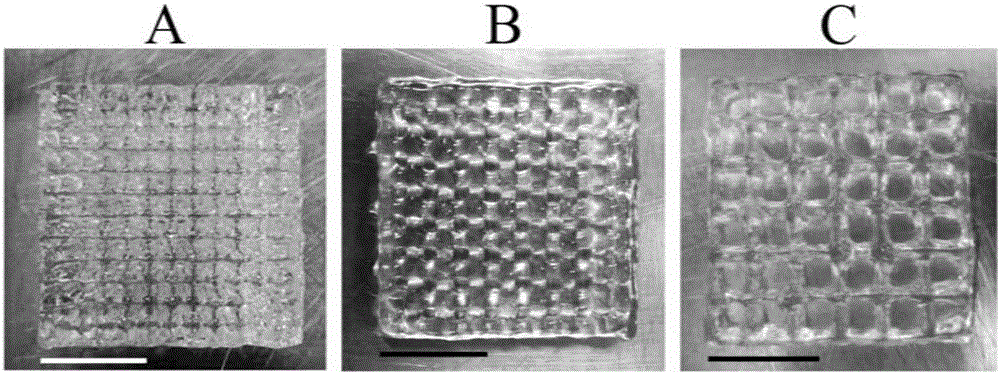

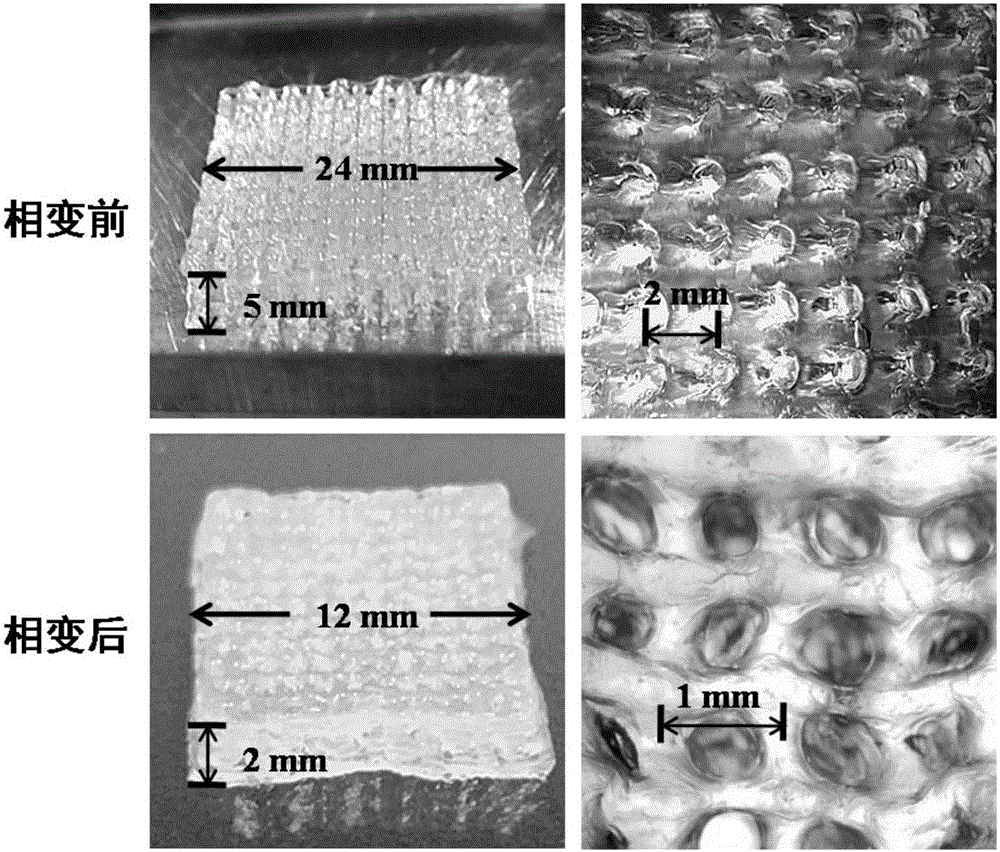

[0023] (2) Use the 3D bioprinter to adjust the 3D printing parameters, which are: the temperature of the barrel is 30°C, the inner diameter of the needle is 0.20mm, the printing speed is 5mm / s, the distance between the XY axes is 2, 3, 4mm, and the lines between layers The rotation angle is 90°, the Z-axis step height is 0.2mm, the Z-axis layer height is 25 layers, the extrusion pressure is 2.5Bar, and the printing platform temperature is 35°C. Finally, a preliminarily formed grid-like 3D printed hydroxybutyl chitosan hydrogel scaffold was obtained.

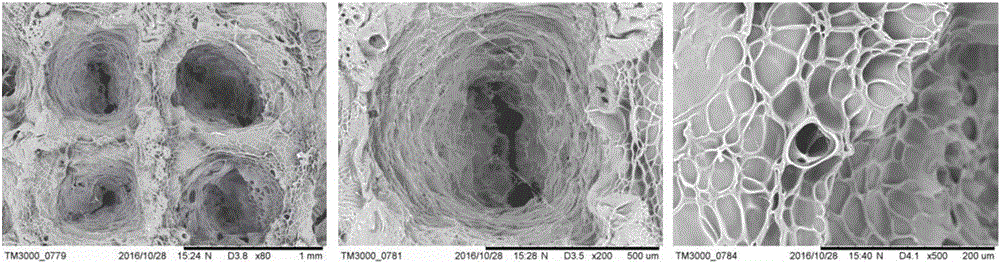

[0024] (3) Soak the preliminarily for...

Embodiment 2

[0027] (1) Take hydroxybutyl chitosan with a hydroxybutyl substitution degree of 1.1, dissolve it in pure water to form a sol of 10.0 mg / mL, load it in a 3D printing cylinder, and let it stand at 4°C for defoaming, and then Place it in a water bath at 28°C and raise the temperature for 20 minutes to cause a gelation transition to obtain a hydrogel that can be used for 3D printing.

[0028] (2) Use the 3D bioprinter to adjust the 3D printing parameters, which are: the temperature of the barrel is 28°C, the inner diameter of the needle is 0.20mm, the printing speed is 8mm / s, the distance between the XY axes is 1.0mm, and the step height of the Z axis is 0.3 mm, the extrusion pressure is 2.1Bar, and the temperature of the printing platform is 35°C. The interlayer angle of the lines from the first layer to the third layer is 90°, and the interlayer angle of the lines from the third layer to the fifth layer is 0°. Finally, a preliminary formed 3D printed hydroxybutyl chitosan hydr...

Embodiment 3

[0032] (1) Take hydroxybutyl chitosan with a hydroxybutyl substitution degree of 2.8, dissolve it in pure water to form a sol of 9.0 mg / mL, load it in a 3D printing cylinder, and let it stand at 3°C for defoaming, and then Place it in a water bath at 25°C and raise the temperature for 20 minutes to make it undergo a gelation transition to obtain a hydrogel that can be used for 3D printing.

[0033] (2) Use the 3D bioprinter to adjust the 3D printing parameters, which are: the temperature of the barrel is 25°C, the inner diameter of the needle is 0.13mm, the printing speed is 3mm / s, the distance between the XY axes is 1.0mm, and the step height of the Z axis is 0.2 mm, the extrusion pressure is 3.1Bar, and the temperature of the printing platform is 30°C. The interlayer angle of the lines from the first layer to the third layer is 90°, and the interlayer angle of the lines from the third layer to the fifth layer is 0°. Finally, a preliminary formed 3D printed hydroxybutyl ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Storage modulus | aaaaa | aaaaa |

| Loss modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com