Lubricating hydrogel material, and preparation method and application thereof

A gel material, lubricating water technology, used in prosthesis, tissue regeneration, medical science, etc., can solve the problem of difficult to achieve balance between high strength and water content of synthetic cartilage, poor biocompatibility, limited self-healing ability, etc. problem, to achieve the effect of high strength, simple operation and wide pH response range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

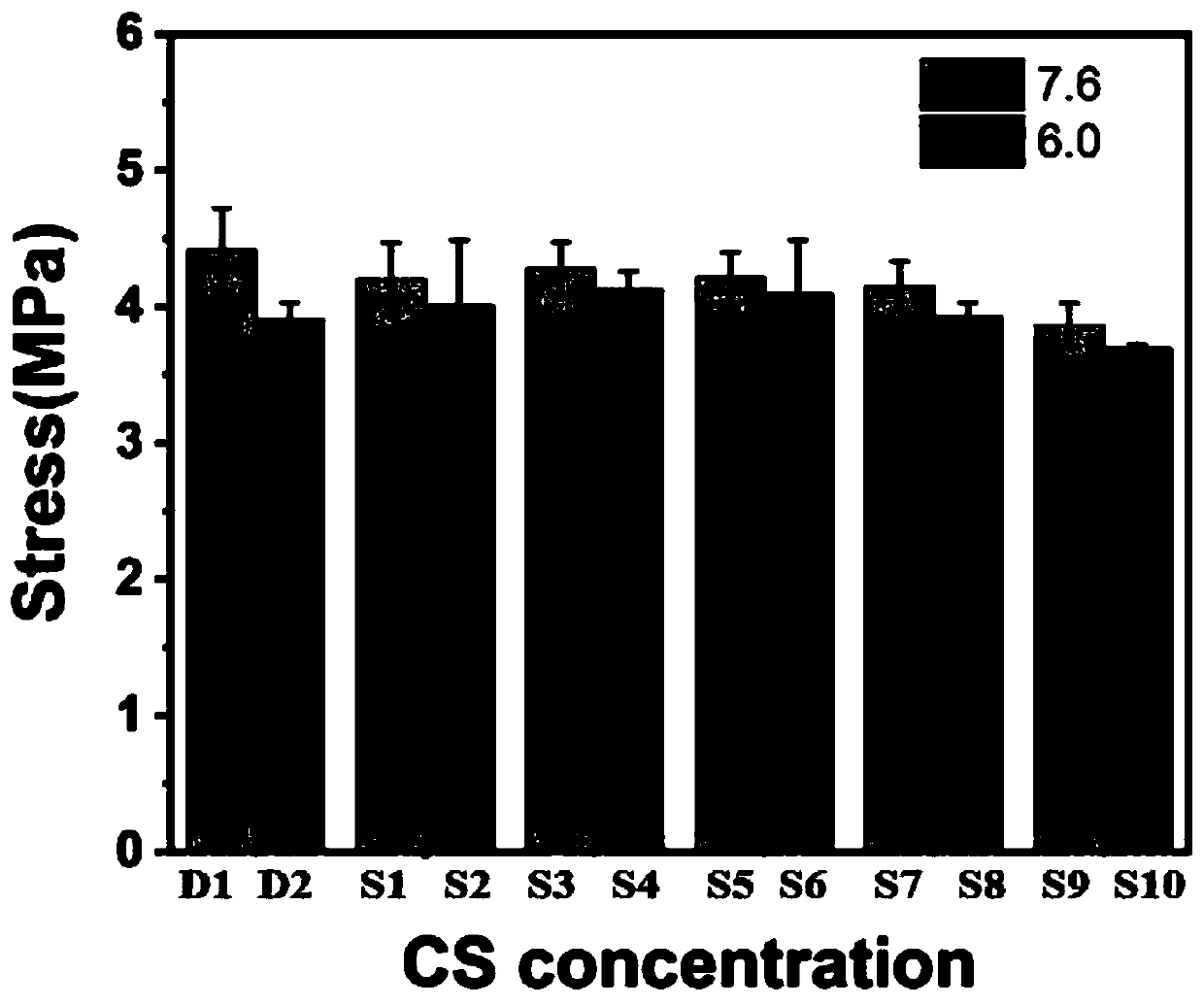

Examples

preparation example Construction

[0033] The invention provides a preparation method of a lubricating hydrogel material, comprising the following steps:

[0034] (1) mixing the first monomer, photoinitiator, crosslinking agent and solvent, and performing the first ultraviolet irradiation treatment to obtain a single network hydrogel;

[0035] (2) mixing the second monomer, supramolecular monomer, photoinitiator, crosslinking agent and solvent to obtain a reaction solution;

[0036] (3) soaking the single-network hydrogel into the reaction solution, and performing a second ultraviolet irradiation treatment to obtain an interpenetrating network hydrogel;

[0037] (4) mixing the interpenetrating network hydrogel material and a pH regulator to swell to obtain a lubricating hydrogel material;

[0038] The step (1) and step (2) have no temporal sequence;

[0039] The first monomer and the second monomer independently include amide monomers, acrylic monomers, [2-(acryloyloxy) ethyl] trimethylammonium chloride, poly...

Embodiment 1

[0072] (1) At room temperature, 20.725g of 2-acrylamide-2-methylpropanesulfonate sodium solid powder and 50mL of deionized water were added to a 100mL Erlenmeyer flask, and magnetically stirred at a speed of 600r / min for 3h. Dissolve the solid powder; add 0.07305g ketoglutaric acid solid powder and 0.30834g N,N-dimethylacrylamide solid powder, stir magnetically at a speed of 600r / min for 2h to dissolve the solid; add the resulting mixed solution into the mold, Irradiate for 20 minutes under ultraviolet light with a wavelength of 365nm to obtain a single-network hydrogel;

[0073] (2) At room temperature, add 85.296g of acrylamide solid powder and 300mL of deionized water into a 500mL Erlenmeyer flask, stir magnetically at a speed of 600r / min for 2h to dissolve the solid powder; add 1.532g of ketoglutaric acid Solid powder and 0.1850g N,N-dimethylacrylamide solid powder were magnetically stirred for 2h to dissolve the solid; 1.8g chitosan solid powder was added, 3mL acetic acid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com