A kind of preparation method of grease-based dual curing resin monomer

A technology for curing resins and monomers, applied in the field of dual-curing resin monomers, can solve problems such as difficult application, achieve energy saving, wide source of raw materials, and ensure reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

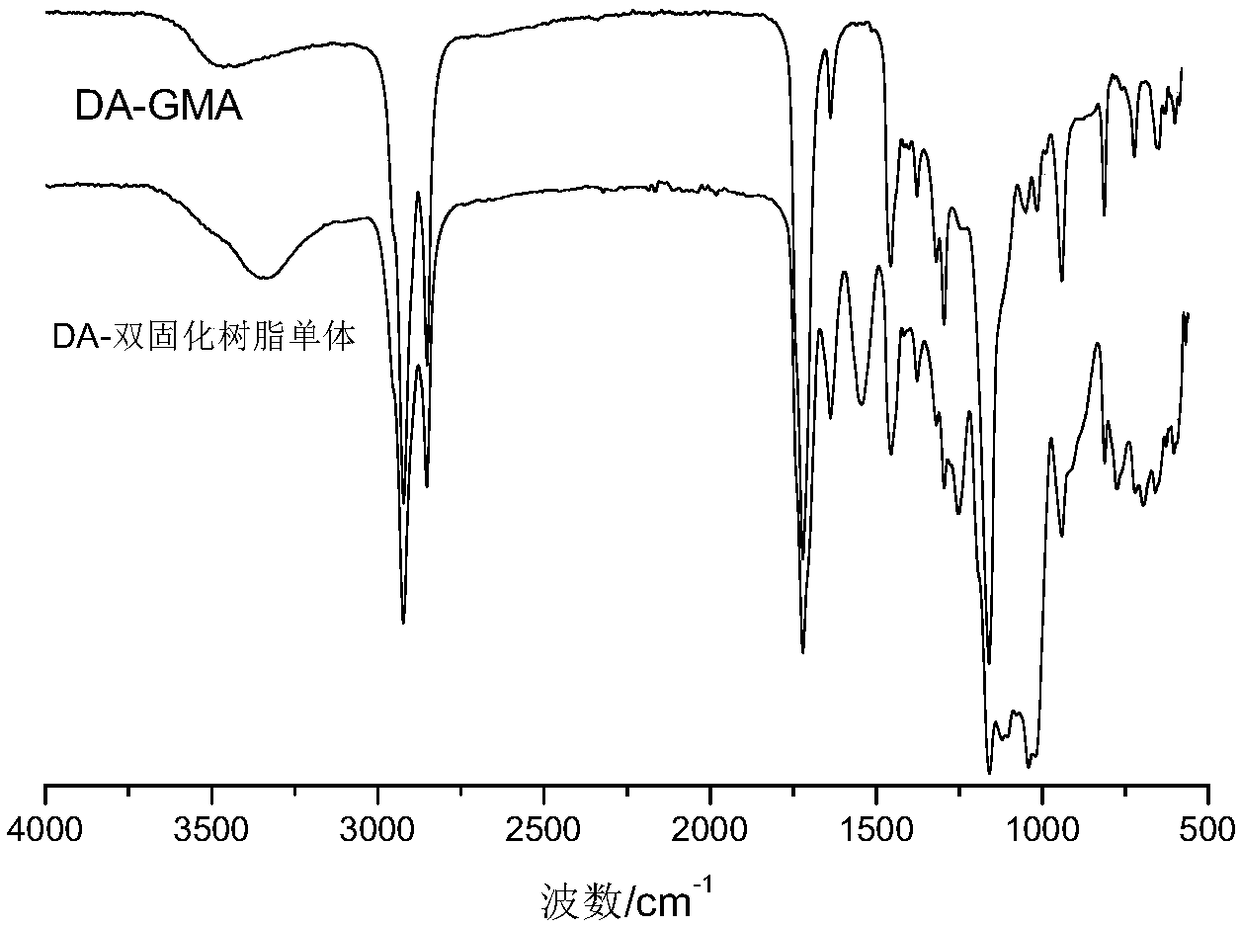

Image

Examples

Embodiment 1

[0019] Add the dimerized fatty acid into the reactor, raise the temperature to 70°C, then add glycidyl methacrylate into the reaction vessel according to the molar ratio of dimerized fatty acid to glycidyl methacrylate 1:2, and then add the Add 0.5% dodecyltrimethoxyammonium chloride and 0.1% 2,5-di-tert-butylhydroquinone to the total mass of the mixture, raise the temperature to 120° C. and keep stirring for 2.5 hours to obtain intermediate product A. Then, the intermediate product A and propyltrimethoxysilane isocyanate were added into the reactor at a molar ratio of 1:2, and reacted at 25° C. for 4 hours to obtain a UV-moisture dual-curable resin monomer.

Embodiment 2

[0021] Add citronic acid dibasic acid to the reactor, heat up to 80°C, then add glycidyl methacrylate into the reaction vessel according to the molar ratio of citric acid dibasic acid to glycidyl methacrylate 1:2 , and then add 0.1% octadecyldimethylbenzyl ammonium chloride and 0.5% hydroquinone, which account for the total mass of the above reactants, and heat up to 115° C. and continue to stir for 1.5 h to obtain intermediate product A. Then, the intermediate product A and propyltriethoxysilane isocyanate were added into the reactor at a molar ratio of 1:4, and reacted at 60°C for 2 hours to obtain a UV-moisture dual-curable resin monomer.

Embodiment 3

[0023] Add tung oil maleic acid into the reactor, heat up to 75°C, then add glycidyl methacrylate into the reaction vessel according to the molar ratio of tung oil maleic acid to glycidyl methacrylate 1:3, and then Add 1.0% octadecyl dimethyl hydroxyethyl ammonium perchlorate and 0.3% 2,5-di-tert-butylhydroquinone, which account for the total mass of the above reactants, heat up to 120°C and continue to stir for 2.0 hours , to obtain the intermediate product A. Then, the intermediate product A and propyltrimethoxysilane isocyanate were added into the reactor at a molar ratio of 1:3, and reacted at 30°C for 3.5 hours to obtain a UV-moisture dual-curable resin monomer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com