Polyurethane foam and modified graphene and preparation methods thereof

A technology of polyurethane foam and graphene, which is applied in the field of packaging materials, can solve the problems of poor cushioning capacity, low strength, and easy agglomeration, and achieve the effects of improved mechanical strength, good mechanical properties, and strong buffering capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] This embodiment provides a polyurethane foam with modified graphene. The polyurethane foam is prepared by mixing and foaming white material and black material. The raw material of white material includes modified graphene. The preparation method of modified graphene includes: After the graphene oxide reacts with the foam stabilizer, it reacts with a reducing agent; wherein, the foam stabilizer is a polysiloxane-polyoxyalkylene copolymer.

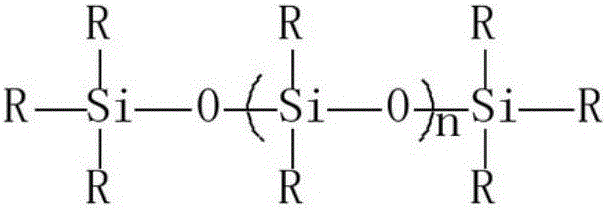

[0022] In a preferred embodiment of the present invention, the basic structural unit of polysiloxane-polyoxyalkylene copolymer is:

[0023]

[0024] Wherein, R is one or more of an alkyl group, an aryl group, hydrogen, a hydroxyl group, an alkoxy group, an acetoxy group, a carbon functional group and a polyether chain.

[0025] Polysiloxane-polyoxyalkylene copolymer is non-hydrolyzable and highly active. The foam stabilizer with this structure has various structures and is often used as a raw material for the production of polyuret...

Embodiment 1

[0053] The present embodiment provides a kind of modified graphene, and the preparation method of this modified graphene is:

[0054] Ultrasonic disperse 3 parts of graphene oxide in a mixed solution of 150 parts of water and ethanol (the volume ratio of water and ethanol is 1:2), then mix with 1 part of foam stabilizer and stir at 50°C for 4 hours, filter and wash The resulting solid was dispersed in 100 parts of water, then mixed with 0.5 parts of sodium borohydride and stirred at 70°C for 8 hours, washed with alcohol and deionized water until the filtrate was neutral, and vacuum-dried to obtain modified graphene.

Embodiment 2

[0056] The present embodiment provides a kind of modified graphene, and the preparation method of this modified graphene is:

[0057] Disperse 4 parts of graphene oxide in a mixed solution of 200 parts of water and methanol (the volume ratio of water to ethanol is 1:1), then mix with 1.5 parts of polysiloxane-polyoxyalkylene copolymer and mix at 30 Stir and react at ℃ for 6h, filter and wash, disperse the obtained solid in 90 parts of water, then mix with 1 part of hydrazine hydrate and stir and react at 80℃ for 7h, wash with alcohol and deionized water until the filtrate is neutral, and vacuum dry Obtain modified graphene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com