Smelting and casting method for 7-series aluminum alloy

An aluminum alloy and casting machine technology, applied in the field of metal smelting, can solve the problems of increasing the coarsening trend of ingot grain size, affecting the mechanical properties of materials, improper process selection, etc., achieving good economic benefits, fewer defects, and reducing production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

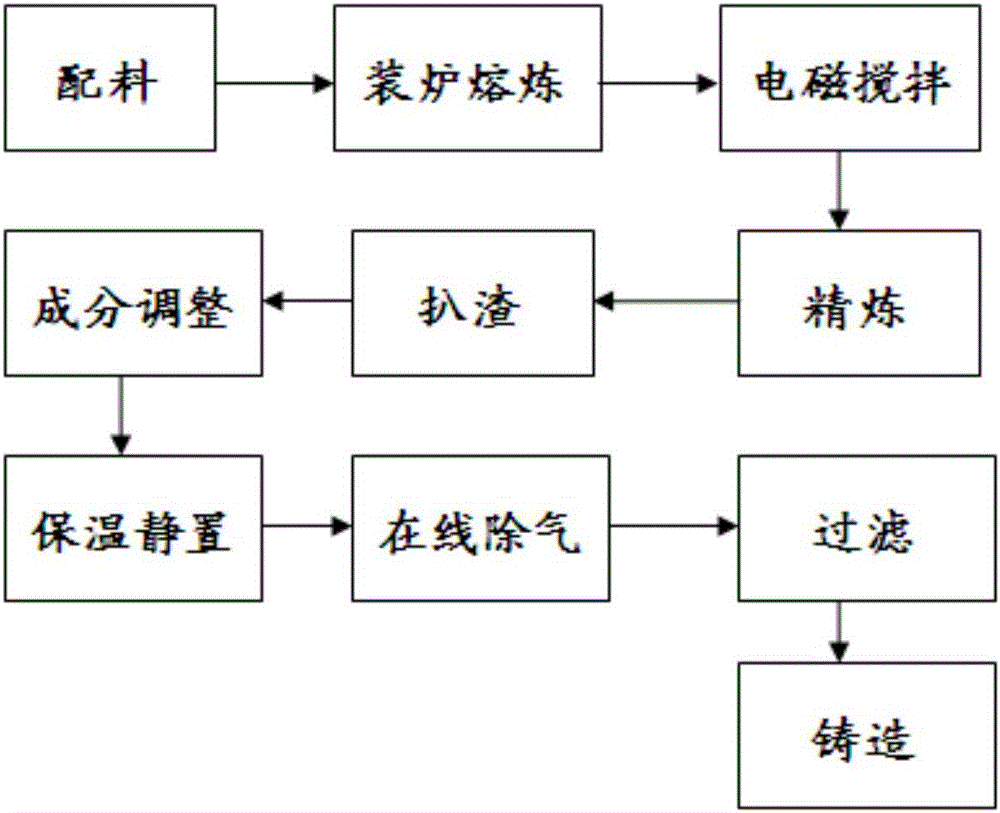

[0030] A 7 series aluminum alloy smelting and casting method includes the following steps:

[0031] 1) Ingredients: ingredients according to the following mass percentages: Si: 0.07%; Fe: 0.15%; Cu: 2.0%; Mg: 2.3%; Zn: 6.4%; Ti: 0.03%, Zr: 0.1%; impurity: single≤0.05 %, the total amount is ≤0.15%; the rest is aluminum;

[0032] 2) Melting: After inputting raw materials, control the melting temperature to 740℃;

[0033] 3) Electromagnetic stirring: During the smelting process, the raw materials are melted and the electromagnetic stirring is turned on to ensure that the raw materials in the furnace melt quickly and the temperature and composition are uniform;

[0034] 4) Refining: add sodium-free refining agent to the melt for refining, the refining temperature is 730℃, the refining time is 8min, after refining, let stand for 10min, during the refining process, the suspended solids and bubbles in the melt are quickly floated by electromagnetic stirring. Eliminate the quality problems o...

Embodiment 2

[0050] A 7 series aluminum alloy smelting and casting method includes the following steps:

[0051] 1) Ingredients: ingredients according to the following mass percentages: Si: 0.05%; Fe: 0.10%; Cu: 2.2%; Mg: 2.4%; Zn: 6.7%; Ti: 0.01%, Zr: 0.1%; impurity: single≤0.05 %, the total amount is ≤0.15%; the rest is aluminum;

[0052] 2) Melting: After inputting raw materials, control the melting temperature to 760℃;

[0053] 3) Electromagnetic stirring: During the smelting process, the raw materials are melted and the electromagnetic stirring is turned on to ensure that the raw materials in the furnace melt quickly and the temperature and composition are uniform;

[0054] 4) Refining: add sodium-free refining agent to the melt for refining, the refining temperature is 750°C, the refining time is 8min, after refining, let stand for 10min, during the refining process, the suspended solids and bubbles in the melt are quickly floated by electromagnetic stirring. Eliminate the quality problems ...

Embodiment 3

[0070] A 7 series aluminum alloy smelting and casting method includes the following steps:

[0071] 1) Ingredients: ingredients according to the following mass percentages: Si: 0.03%; Fe: 0.03%; Cu: 2.1%; Mg: 2.4%; Zn: 6.8%; Ti: 0.03%, Zr: 0.1%; impurity: single ≤0.05 %, the total amount is ≤0.15%; the rest is aluminum;

[0072] 2) Melting: After inputting raw materials, control the melting temperature to 750°C;

[0073] 3) Electromagnetic stirring: During the smelting process, the raw materials are melted and the electromagnetic stirring is turned on to ensure that the raw materials in the furnace melt quickly and the temperature and composition are uniform;

[0074] 4) Refining: add sodium-free refining agent to the melt for refining, the refining temperature is 740℃, the refining time is 7min, after refining, let it stand for 10min, during the refining process, the suspended solids and bubbles in the melt are quickly floated by electromagnetic stirring. Eliminate the quality probl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com