Catalyst for coal gasification, preparation method and application thereof

A coal gasification and catalyst technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, organic compounds/hydrides/coordination complex catalysts, etc., can solve the corrosion of reactor metal components, difficulty in catalyst recovery, and affect the reaction issues such as device life, to achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

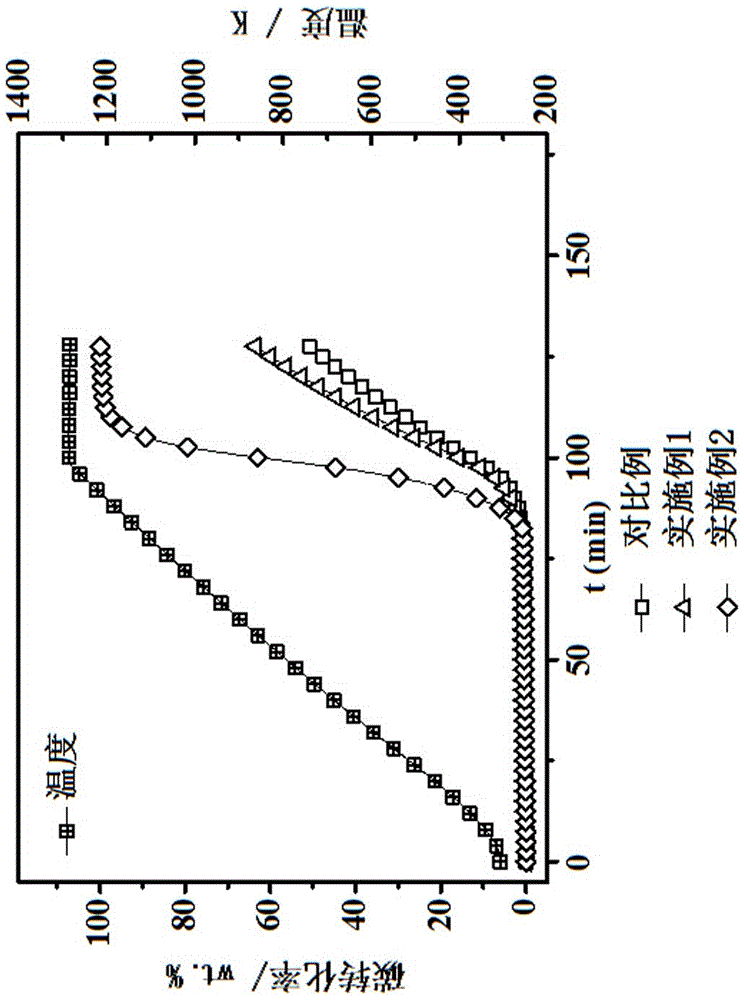

[0038] In this embodiment 1, except that hydrofluoric acid is used to carry out the acid elution demineralization treatment step on the Jincheng low-quality coal, the rest of the steps are the same as the comparative example 1. The acid-eluting demineralization treatment step is: using 5% (wt.%) hydrofluoric acid solution to pickle and demineralize the coal, at a ratio of 10g coal: 250ml hydrofluoric acid solution, at 60°C, Stir for 30 minutes, filter and wash with deionized water until the filtrate is neutral, and then dry in an oven at 105°C; after acid elution, the mineral content in the coal is reduced to 12.4wt%.

[0039] The demineralized coal and rice straw are mixed and contacted at a mass ratio of 1:1, and then heated under 800° C. 2 A total of 30 minutes of pyrolysis under the atmosphere. The co-pyrolysis product is repeatedly sieved, and the generated coal char and biomass char are separated to obtain the catalyst for coal gasification of the present invention. Th...

Embodiment 2

[0042] In Example 2, except that hydrofluoric acid was used to carry out the acid elution demineralization treatment step on the Jincheng inferior coal, the rest of the steps were the same as those in Comparative Example 1. The acid-eluting demineralization treatment step is: using 20% (wt.%) hydrofluoric acid solution to pickle and demineralize the coal, at a ratio of 10g coal: 250ml hydrofluoric acid solution, at 60°C, Stir for 30 min, filter and wash with deionized water until the filtrate is neutral, and then dry in an oven at 105°C. After acid leaching mineral treatment, the mineral content in the coal was reduced to 4.5wt%.

[0043] The above-mentioned demineralized coal and rice straw were mixed and contacted at a mass ratio of 1:1, and then heated under 800°C N 2 A total of 30 minutes of pyrolysis under the atmosphere. The co-pyrolysis product is repeatedly sieved, and the generated coal char and biomass char are separated to obtain the catalyst for coal gasificati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com