Process for efficiently recovering reforming gas energy in hydrocarbon steam reforming hydrogen production process

A technology for reforming gas and steam, which is applied in the field of petrochemical industry. It can solve the problems of no pressure energy, large heat transfer temperature difference of waste heat boiler, and low energy efficiency of the second law, so as to increase the output energy of the device, reduce the energy consumption of the device, and increase the operation flexibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

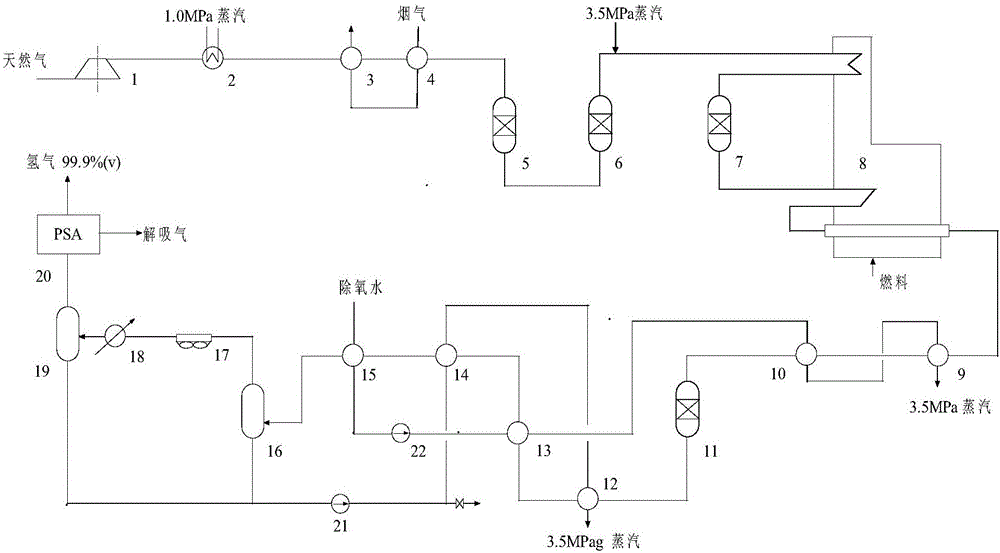

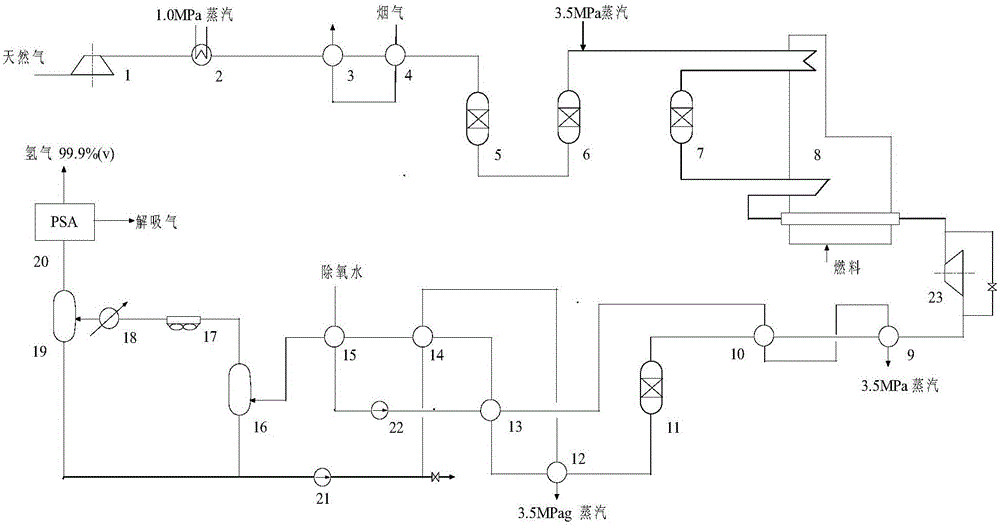

[0030] This embodiment is a process for efficiently recovering reformed gas energy in the hydrogen production process of hydrocarbon steam reforming, and its process flow is as follows figure 2 shown. Specific steps are as follows:

[0031] The raw natural gas from the pipeline network enters the natural gas preheater 2 after being boosted by the natural gas compressor 1, is preheated by the 1.0MPa steam from the pipeline network, and then enters the flue gas of the reformer ~ the raw material preheater 3 and 4, and further heats up Then it enters hydrogenation reactor 5 and desulfurization reactor 6 to remove harmful elements such as sulfur and arsenic. Then it is injected with 3.5MPa saturated steam, enters the convection section of the reformer 8 with a suitable water-to-carbon ratio, and enters the pre-reforming reactor 7 and the furnace tube of the reformer 8 after heating up. Light hydrocarbons and water vapor undergo conversion reactions in the furnace tube to genera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com