Lignin-based two-dimensional carbon nano-material as well as preparing method and application thereof

A carbon nanomaterial and lignin-based technology, which is applied in the field of lignin-based two-dimensional carbon nanomaterials and their preparation, carbon materials and their preparation, can solve the problems of single material morphology, complex preparation method steps, no specific structure and the like , to achieve the effect of simple preparation process, good application prospect and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

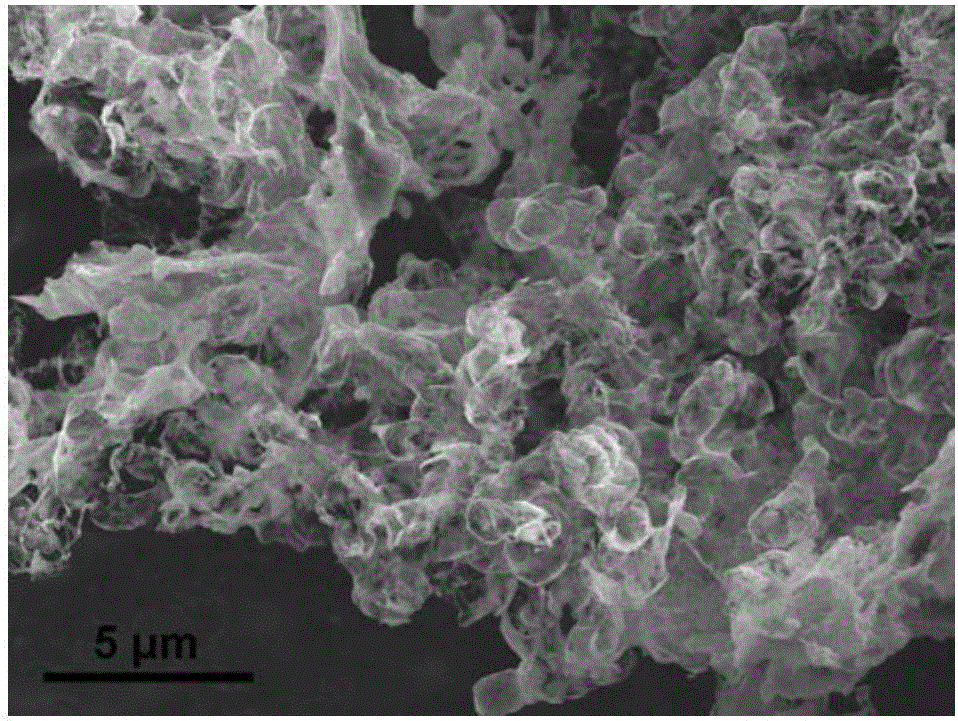

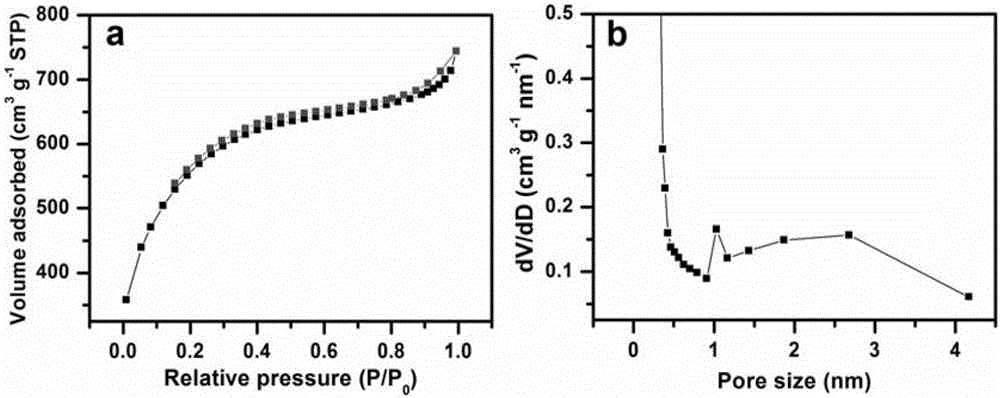

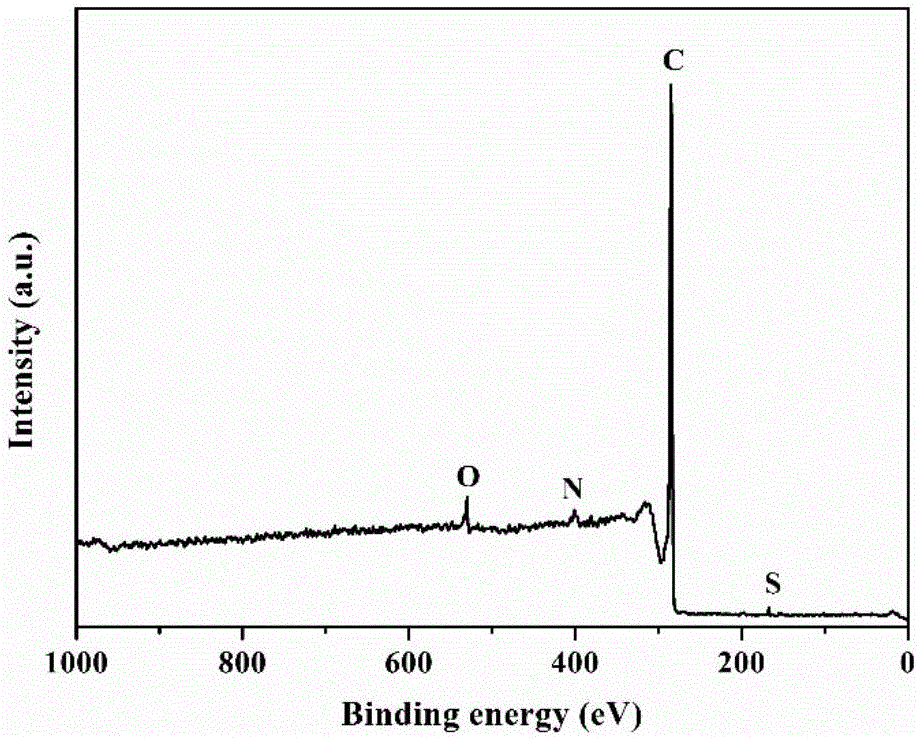

[0035] Add 10 mL of deionized water, 2 g of lignin and 2 g of ammonium chloride to the beaker, stir for 10 min to obtain a mixture, and put the mixture into an alumina crucible after freeze-drying. The temperature was raised to 1000°C at 5°C / min, kept at this temperature for 5h, and then naturally cooled to room temperature, washed with deionized water, and dried to obtain a carbon material product. figure 1 For the scanning electron microscope (SEM) picture of the two-dimensional carbon nanomaterial prepared in embodiment 1, from figure 1 It can be seen that the obtained two-dimensional carbon nanomaterial has a curled sheet structure, the lateral size of the sheet is 2-5 μm, and the thickness of the sheet is about 20 nm; figure 2 For the nitrogen adsorption-desorption curve (a) and pore distribution figure (b) of the two-dimensional carbon nanomaterial prepared in embodiment 1, from figure 2 It can be seen that the specific surface area of the obtained material is 1880m...

Embodiment 2

[0037] Add 10 mL of deionized water, 2 g of lignin and 20 g of urea into the beaker, fully dissolve to obtain a mixture, and put the mixture into an alumina crucible after freeze-drying. The temperature was raised to 450°C in min, kept at this temperature for 1h, then raised to 900°C at 5°C / min, kept at this temperature for 3h, then naturally cooled to room temperature, washed with deionized water, and dried to obtain a carbon material product. Figure 5 For the scanning electron microscope (SEM) figure of the two-dimensional carbon nanomaterial prepared in embodiment 2, from Figure 5 It can be seen that the material prepared in this embodiment is a porous material composed of a lamellar structure; Image 6 For the nitrogen adsorption-desorption curve (a) and pore distribution figure (b) of the two-dimensional carbon nanomaterial prepared in embodiment 2, from Image 6 It can be seen that the specific surface area of the obtained material is 465.68m 2 / g, is a porous materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com