Quantum dot ink and preparation method thereof

A quantum dot and ink technology, applied in the field of quantum dot ink and its preparation, can solve the problems of low quality of quantum dots, easy blockage of nozzles, poor display effect, etc., and achieve the effect of simple ingredients, ensuring brightness and clarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

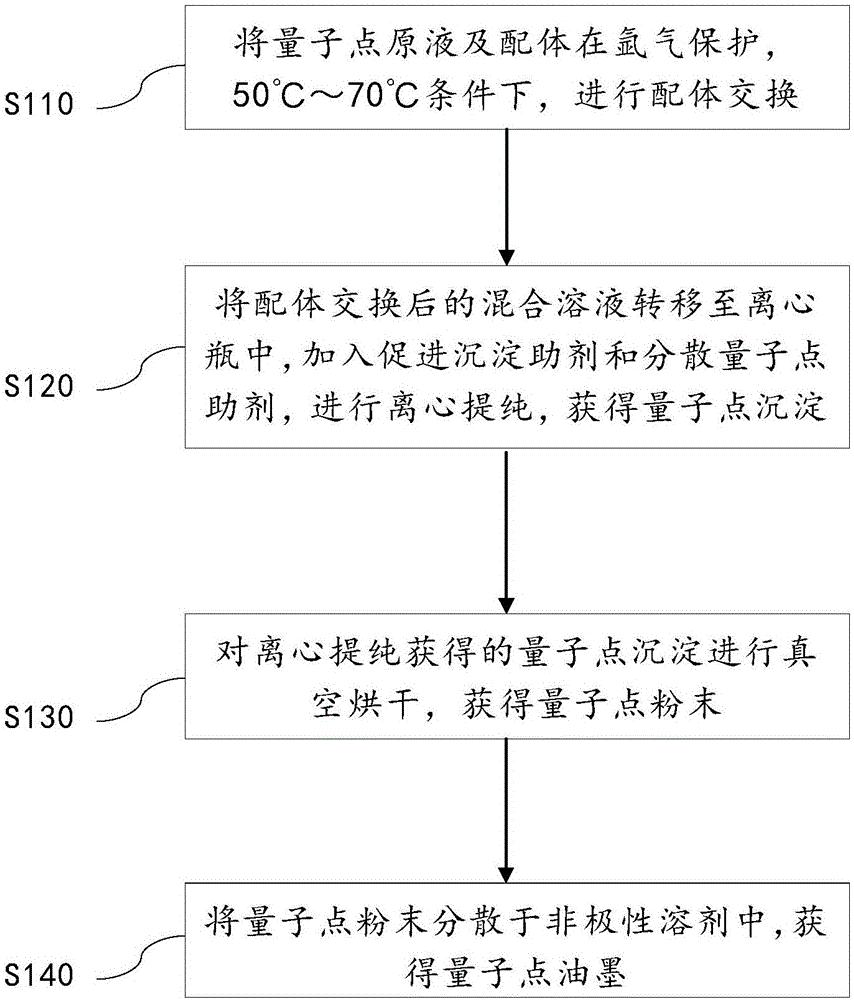

Method used

Image

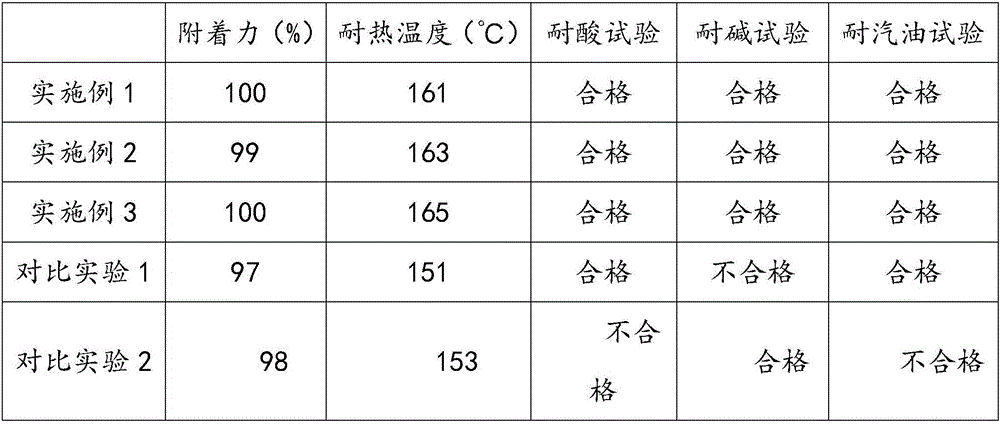

Examples

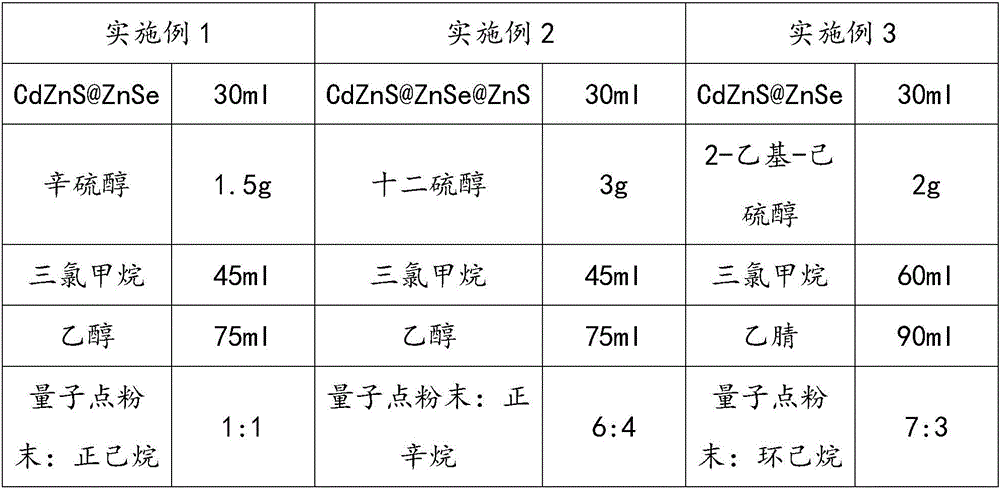

Embodiment 1

[0027] The preparation method of embodiment 1

[0028] In step 1, the oleic acid ligand in the quantum dot stock solution containing quantum dot CdZnS@ZnSe and the thiol ligand on octyl thiol are heated to 60 ° C under the protection of argon, and the ligand is exchanged by magnetic stirring; in the step In the second step, add 45ml of chloroform to the solution after the ligand exchange to dilute and disperse the quantum dot stock solution, add 75ml of ethanol to promote the precipitation of quantum dots, and carry out heart purification under the condition of 10000r / min to obtain quantum dot precipitation; In step 3, the quantum dot precipitation obtained in step 2 is vacuum-dried to obtain quantum dot powder; in step 4, an equal amount of dried quantum dot powder is mixed with n-hexane solution to obtain quantum dot ink.

[0029] Through the above four steps, in the obtained quantum dot ink, the quantum dot content in the quantum dot reaches 50%, and the viscosity meets the...

Embodiment 2

[0030] The preparation method of embodiment 2

[0031] In step 1, the oleic acid ligand in the quantum dot stock solution containing quantum dots CdZnS@ZnSe@ZnS and the thiol ligand on dodecanethiol are heated to 60°C under the protection of argon, and the ligands are exchanged by magnetic stirring. ; In step 2, add 45ml chloroform to the solution after the ligand exchange to dilute the dispersed quantum dot stock solution, add 75ml ethanol to promote the precipitation of quantum dots, and carry out heart purification under the condition of 10000r / min to obtain quantum dots Dot precipitation; in step three, vacuum-dry the quantum dot precipitation obtained in step two to obtain quantum dot powder; in step four, dry the quantum dot powder and n-octane solution in a mass ratio of 6:4 Mix to get quantum dot ink.

[0032] Through the above four steps, in the obtained quantum dot ink, the quantum dot content in the quantum dot reaches 60%, and the viscosity meets the requirement o...

Embodiment 3

[0033] The preparation method of embodiment 3

[0034] In step 1, the oleic acid ligand and the mercapto ligand of 2-ethyl-hexanethiol in the quantum dot stock solution containing quantum dots CdZnS@ZnSe are heated to 60 ° C under the protection of argon, and the ligands are stirred by magnetic force. Exchange; in step 2, add 60ml of chloroform to the solution after ligand exchange to dilute and disperse the stock solution, add 90ml of acetonitrile to promote the precipitation of quantum dots, and perform centrifugal purification under the condition of 10000r / min to obtain quantum dots Precipitation; in step 3, vacuum-dry the quantum dot precipitation obtained in step 2 to obtain quantum dot powder; in step 4, mix the dried quantum dot powder with cyclohexane solution in a mass ratio of 7:3 , to obtain quantum dot ink.

[0035] Through the above four steps, in the quantum dot ink obtained, the quantum dot content in the quantum dot reaches 70%, and the viscosity meets the req...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com