Combined type bio-membrane reactor combined with mycelium pellet and method for phenolic waste water treatment by bio-membrane reactor

A technology of biofilm reactor and mycelium ball, which is applied in the direction of specific-purpose bioreactor/fermenter, method of supporting/immobilizing microorganisms, combination of bioreactor/fermenter, etc., can solve the problem of high cost of phenol wastewater, Achieve the effect of increasing the amount of bacteria, improving the efficiency of operation and treatment, and solving the loss of bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

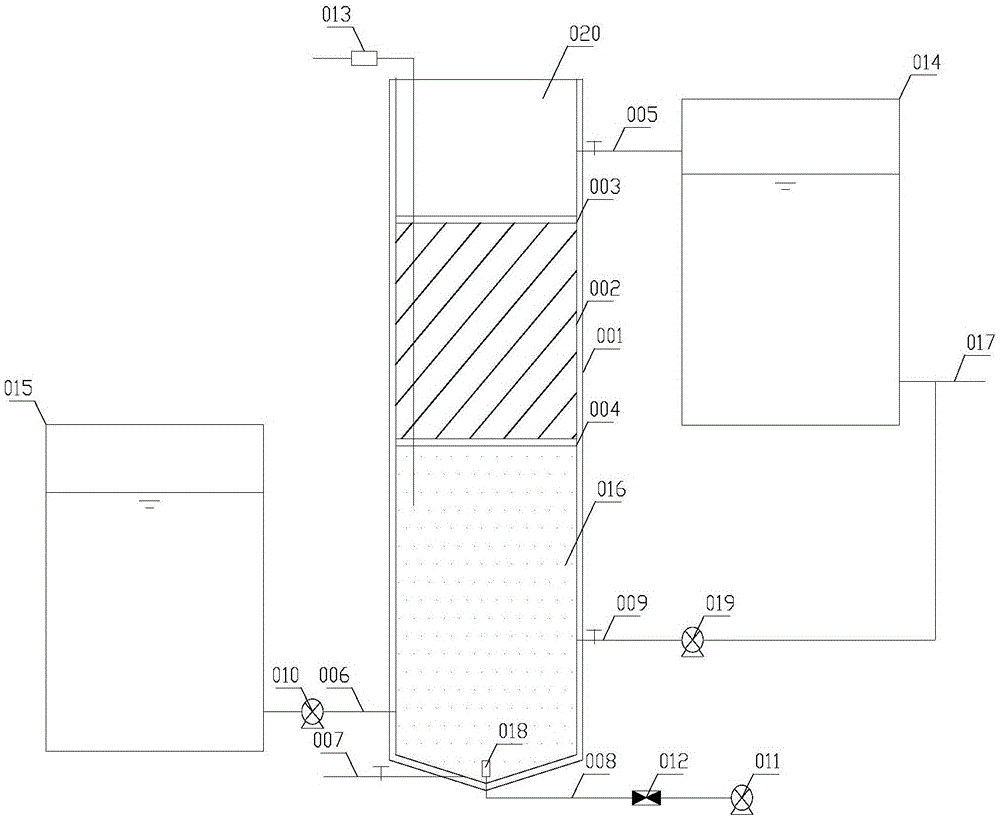

[0018] Specific embodiment 1: This embodiment is a combined biofilm reactor combined with mycelium pellets, which includes a reactor main body 001, a first water outlet pipe 005, a water inlet pipe 006, a vent pipe 007, an air inlet pipe 008, Reflux pipe 009, first water storage tank 015, second water storage tank 014, second water outlet pipe 017 and aeration head 018; the reactor body 001 includes a water storage area 020, a packing area 002 and a reaction containing mycelial pellets Zone 016, and the water storage zone 020, the filling zone 002, and the reaction zone 016 containing mycelium pellets are arranged from top to bottom; the first water storage tank 015 passes through the water inlet pipe 006 and the reaction zone containing the mycelium pellets The lower end of 016 is connected; the water storage area 020 is connected to the second water storage tank 014 through the first water outlet pipe 005; the lower end of the second water storage tank 014 is provided with a s...

specific Embodiment approach 2

[0020] Embodiment 2: The difference between this embodiment and the first embodiment is that a cover plate 003 is arranged above the packing area 002, a water distribution plate 004 is arranged below the packing area 002, and the packing area 002 is arranged in the reactor. The inside of the main body 001 is 1 / 4 to 1 / 2 from top to bottom. The other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0021] Specific embodiment three: this embodiment is different from specific embodiment one or two in that: an air pump 011 and a flow meter 012 are provided on the intake pipe 008. The other steps are the same as the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com