Silver loaded mesoporous silicon oxide coated ternary cathode material, and preparation method and applications thereof

A technology of positive electrode material and silicon oxide, which is applied in the field of silver-loaded mesoporous silicon oxide-coated ternary positive electrode material and its preparation, and can solve the problems such as difficulty in increasing the specific capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

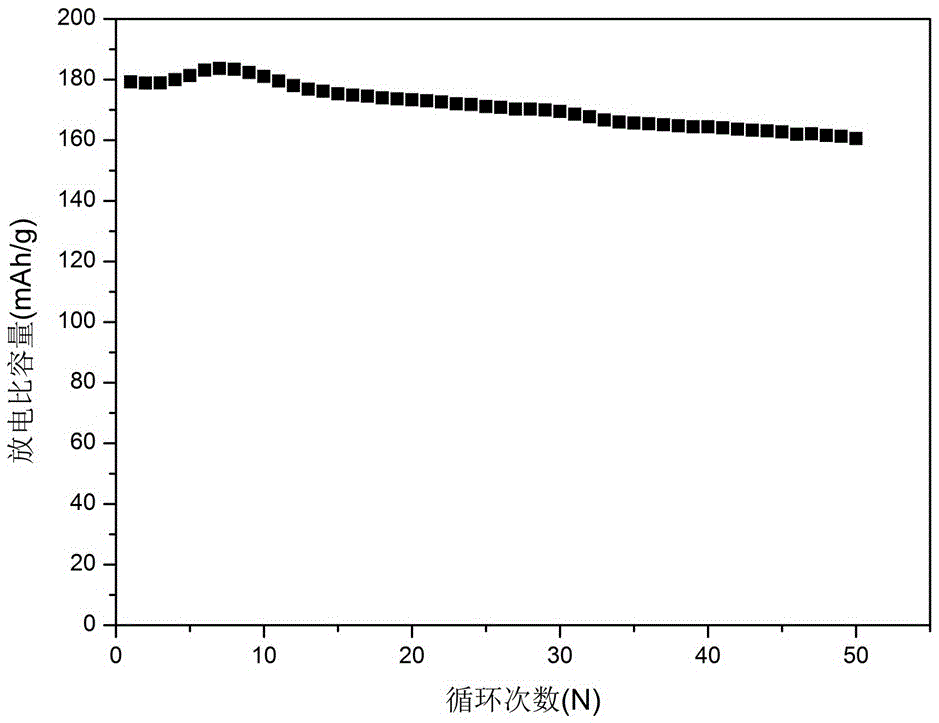

Image

Examples

Embodiment 1

[0023] (1) Add lithium acetate, nickel acetate, cobalt acetate and manganese acetate into deionized water at a molar ratio of 0.01 mol:0.0033 mol :0.0033 mol :0.0033 mol and stir until the metal salts are completely dissolved; Mix the double chelating agent EDTA-CA with a small amount of deionized water to moisten, add ammonia water, shake until a colorless and transparent solution is formed, then add the colorless and transparent double chelating agent solution into the uniform medium of inorganic salts to form a blue-purple transparent solution, 70 ℃ heating and stirring until a blue-purple sol is formed; heating and stirring at 80 ℃ until a blue-purple sol is formed; the gel material is heated in a blast drying oven at 240 ℃ until a black porous xerogel is formed; the obtained black xerogel is ground into powder, calcined at 850 °C for 5 h in a muffle furnace to obtain LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 .

[0024] (2) LiNi in step (1) 1 / 3 co 1 / 3 mn 1 / 3 o 2 The aqueous sol...

Embodiment 2

[0027] (1) Add lithium nitrate, nickel nitrate, cobalt nitrate and manganese nitrate into deionized water at a molar ratio of 0.01 mol: 0.005 mol: 0.003 mol: 0.002 mol and stir until the metal salts are completely dissolved; Mix the double chelating agent EDTA-PPA with a small amount of deionized water to moisten, add ammonia water, shake until a colorless and transparent solution is formed, then add the colorless and transparent double chelating agent solution into the uniform medium of inorganic salts to form a blue-purple transparent solution, 80 ℃ heating and stirring until a blue-purple sol is formed; heating and stirring at 80 ℃ until a blue-purple sol is formed; the gel material is heated in a blast drying oven at 240 ℃ until a black porous xerogel is formed; the obtained black xerogel is ground into powder, calcined at 850 °C for 5 h in a muffle furnace to obtain LiNi 0.5 co 0.3 mn 0.2 o 2 .

[0028] (2) LiNi in step (1) 0.5 co 0.3 mn 0.2 o 2 The aqueous soluti...

Embodiment 3

[0031] (1) Add lithium nitrate, nickel nitrate, cobalt nitrate and manganese nitrate into deionized water at a molar ratio of 0.01 mol: 0.008 mol: 0.001 mol: 0.001 mol and stir until the metal salts are completely dissolved; Mix the double chelating agent EDTA-PPA with a small amount of deionized water to moisten, add ammonia water, shake until a colorless and transparent solution is formed, then add the colorless and transparent double chelating agent solution into the uniform medium of inorganic salts to form a blue-purple transparent solution, 80 Heat and stir at 80°C until a blue-purple sol is formed; heat and stir at 80°C until a blue-purple sol is formed; heat the gel material in a blast drying oven at 240°C until a black porous xerogel is formed; grind the obtained black xerogel into powder, calcined at 850 °C for 5 h in a muffle furnace to obtain LiNi 0.8 co 0.1 mn 0.1 o 2 .

[0032] (2) LiNi in step (1) 0.8 co 0.1 mn 0.1 o 2 The aqueous solution was stirred at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com