A kind of lead-acid battery electrolyte delamination alleviating agent

A lead-acid battery and electrolyte technology, applied in lead-acid batteries and other directions, can solve the problems of reducing battery capacity, starting performance and cycle life, etc., and achieve the effect of easy realization of manufacturing process, obvious effect, and reduction of sulfation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

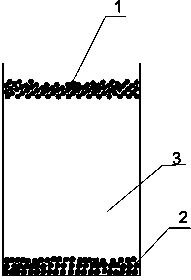

[0036] Figure 1-5 It is the electrolyte delamination mitigation agent of Example 1, and the distribution of the mitigation agent during battery use and the movement and agitation conditions during use.

[0037] Example 1 uses polyvinyl fluoride hollow material, which is granular and has a diameter of 0.5mm to 1.0mm. There are two types of densities, one is 1.2±0.2g / ml, the other is 1.28±0.2g / ml, and the other is 1.28±0.2g / ml. Raw materials of different densities each account for 50%wt, and their total addition is 10%wt of the total amount of electrolyte. so that it can function in different situations.

[0038] The electrolyte density of the new battery is 1.28g / ml, and the electrolyte is evenly distributed. During the movement of the car, due to the inertia generated when the vehicle starts, stops, accelerates, decelerates, etc., the relieving agent of 1.2±0.2g / ml moves on the top layer of the battery, and the relieving agent of 1.28±0.2g / ml moves in the battery The movem...

Embodiment 2

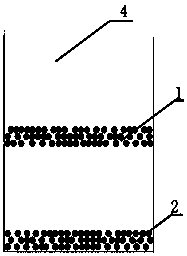

[0042] Figure 6-10 It is the electrolyte delamination mitigation agent of embodiment 2, and the distribution of the mitigation agent during battery use and the stirring situation during use.

[0043]Example 2 uses PVC hollow material, which is granular and has a diameter of 0.6 mm to 1.1 mm. There are two types of density, one is 1.2 ± 0.2 g / ml, and the other is 1.28 ± 0.2 g / ml. The proportions are 60%wt and 40%wt respectively, and the total amount added is 7%wt of the total amount of electrolyte. so that it can function in different situations.

[0044] After a period of use, the density distribution of the battery electrolyte is not uniform, and the densities of the upper, middle and lower parts are 1.22g / ml, 1.25g / ml, and 1.28g / ml, respectively. During the movement of the car, due to the inertia generated when the vehicle starts, stops, accelerates, decelerates, etc., the relieving agent of 1.2±0.2g / ml moves on the top layer of the battery, and the relieving agent of 1.2...

Embodiment 3

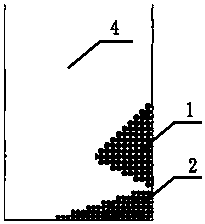

[0048] Figure 11-15 It is the electrolyte delamination mitigation agent of embodiment 3, and the distribution of the mitigation agent during battery use and the stirring situation during use.

[0049] Example 3 uses PP to wrap SiO 2 Solid material, in the form of granules, with a diameter of 0.4mm to 0.9mm. There are two types of density, one is 1.2±0.2g / ml, the other is 1.28±0.2g / ml, and their proportions are 40% respectively wt, 60% wt, the total amount added is 5%wt of the total amount of electrolyte. so that it can function in different situations.

[0050] After a period of use, the density distribution of the battery electrolyte is not uniform, and the densities of the upper, middle, and lower parts are 1.26g / ml, 1.29g / ml, and 1.32g / ml, respectively. During the movement of the car, due to the inertia generated when the vehicle starts, stops, accelerates, decelerates, etc., the relieving agent of 1.2±0.2g / ml moves on the top layer of the battery, and the relieving age...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com