Method for dry storage of artificial heart valve prosthesis

A kind of artificial heart valve, drying technology, applied in the preservation and application of heart valve, human or animal body, etc., can solve the problems of easy calcification of tissue, cytotoxicity, reduce cost, etc., and achieve the effect of high proximity and elimination of side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The artificial heart valve treated with glutaraldehyde is cut into three groups of similar size, each of 6 pieces, wherein the biological tissue material of the artificial heart valve is bovine pericardium. Measure the size and record it. The artificial heart valve was completely immersed in solution A for 12 hours, and then completely immersed in solution B for 12 hours after being removed, and completely immersed in solution C for 12 hours after being removed. Among them, the volume ratio of solutions A, B, C to the artificial heart valve is 80:1, and the distribution of each group is shown in Table 1.

[0055] Table 1

[0056] Solution combination Solution A Solution B Solution C glycerin75%80%85% Ethanol 25%20%15%

[0057] Test items:

[0058] 1. Measure and record the diameter and thickness of the artificial heart valve before processing, after drying, and after hydration. The data are read after 5 seconds of stability. The same artificial heart valve was tested 6...

Embodiment 2-8

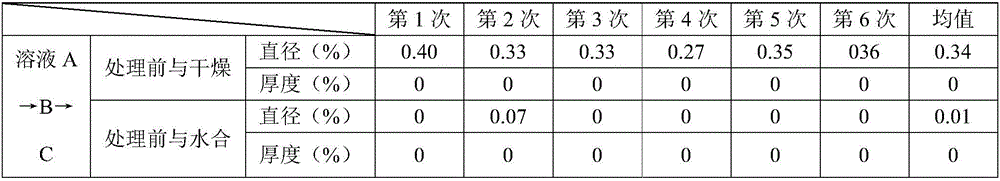

[0075] Prepare solutions A, B, and C with the components shown in Table 7, and contact the artificial heart valve in the order of solution A→B→C. After testing, the diameter and thickness of it before treatment, after drying and after hydration The rate of change is shown in Table 8.

[0076] Table 7

[0077]

[0078]

[0079] Table 8

[0080]

[0081] It can be seen from the above results that in Examples 1-7, solutions A, B, and C are used to contact the artificial heart valve in the order of solution A→B→C, which can make the size of the artificial heart valve after treatment close to the size before dehydration Higher, making the dry tissue less susceptible to microorganisms; in Examples 1-7, Example 1 compared to other Examples 2-7, it can make the size of the artificial heart valve after treatment the closest to the size before dehydration.

[0082] The present invention also verifies other animal pericardium (such as pig, sheep, kangaroo, etc.), aorta, mitral valve, tricuspid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com