Injectable bone repairing material and preparation method thereof

A technology of bone repair and hydroxyapatite, which is applied in the field of medical materials, can solve problems affecting porosity and compressive strength, and achieve good injection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

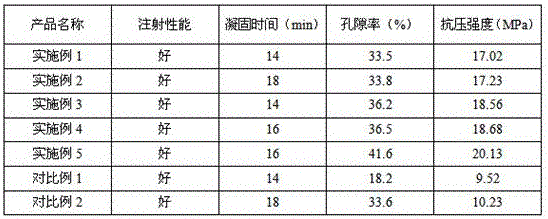

Examples

Embodiment 1

[0017] An injectable bone repair material, prepared from the following ingredients by weight: 30 parts of α-calcium sulfate hemihydrate, 30 parts of hydroxyapatite, 2.5 parts of sodium hyaluronate, 3 parts of octadecanoic acid, carboxymethyl 3 parts of base cellulose, 2.5 parts of calcium sulfate dihydrate, 2 parts of collagen fiber, 3 parts of polyglycolic acid fiber, 2 parts of snail mucus, 2 parts of polyhydroxybutyrate, 8 parts of lactic acid-polyethylene glycol copolymer, 50 parts of ionized water.

[0018] The preparation method of the above-mentioned injectable bone repair material is as follows: (1) Proportionally mix α-calcium sulfate hemihydrate, hydroxyapatite, calcium sulfate dihydrate, collagen fibers, and polyglycolic acid fibers to obtain a solid phase mixture; ( 2) Sodium hyaluronate and carboxymethyl cellulose are dissolved in deionized water to form a solution, and stirred until completely dissolved; (3) Add the solid-phase mixture to the solution in step (2)...

Embodiment 2

[0020] An injectable bone repair material, prepared from the following components by weight: 50 parts of α-calcium sulfate hemihydrate, 20 parts of hydroxyapatite, 15 parts of sodium hyaluronate, 1 part of octadecanoic acid, carboxymethyl 1 part of base cellulose, 4 parts of calcium sulfate dihydrate, 3 parts of collagen fiber, 2 parts of polyglycolic acid fiber, 3 parts of snail mucus, 8 parts of polyhydroxybutyrate, 2 parts of lactic acid-polyethylene glycol copolymer, 80 parts of ionized water.

[0021] The preparation method of the above-mentioned injectable bone repair material is as follows: (1) Proportionally mix α-calcium sulfate hemihydrate, hydroxyapatite, calcium sulfate dihydrate, collagen fibers, and polyglycolic acid fibers to obtain a solid phase mixture; ( 2) Sodium hyaluronate and carboxymethyl cellulose are dissolved in deionized water to form a solution, and stirred until completely dissolved; (3) Add the solid-phase mixture to the solution in step (2) and s...

Embodiment 3

[0023] An injectable bone repair material, prepared from the following components by weight: 35 parts of α-calcium sulfate hemihydrate, 28 parts of hydroxyapatite, 5 parts of sodium hyaluronate, 2.5 parts of octadecanoic acid, carboxymethyl 1.5 parts of base cellulose, 3 parts of calcium sulfate dihydrate, 2.2 parts of collagen fiber, 2.8 parts of polyglycolic acid fiber, 2.2 parts of snail mucus, 4 parts of polyhydroxybutyrate, 6 parts of lactic acid-polyethylene glycol copolymer, 60 parts of ionized water.

[0024] The preparation method of the above-mentioned injectable bone repair material is as follows: (1) Proportionally mix α-calcium sulfate hemihydrate, hydroxyapatite, calcium sulfate dihydrate, collagen fibers, and polyglycolic acid fibers to obtain a solid phase mixture; ( 2) Sodium hyaluronate and carboxymethyl cellulose are dissolved in deionized water to form a solution, and stirred until completely dissolved; (3) Add the solid-phase mixture to the solution in ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com