Porous graphene and preparation method thereof

A technology of porous graphene and porous carbon, applied in graphene, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of low yield, difficult to control the number of graphene layers, and high production cost, and achieve high yield and low realization. Cost-effective mass production and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] The present embodiment provides a kind of preparation method of porous graphene, it comprises the following steps:

[0053] 1) Weigh 10g of oil slurry, heat it to liquid state (60-90°C), add 20g of flake magnesium oxide, stir evenly, put it into a horizontal tube furnace, and then pass argon (Ar) into the furnace, while the horizontal furnace Raise the temperature to 500°C at a heating rate of 15°C / min, and keep it for 60min. After the furnace temperature is naturally cooled to room temperature, take out the gray product; It is obtained by mixing 1:3, wherein the mass percent concentration of concentrated hydrochloric acid is 37%), boiled and refluxed for pickling for 1 hour, and finally washed with deionized water until neutral and dried at 80°C to obtain a porous carbon material, No. for PC500.

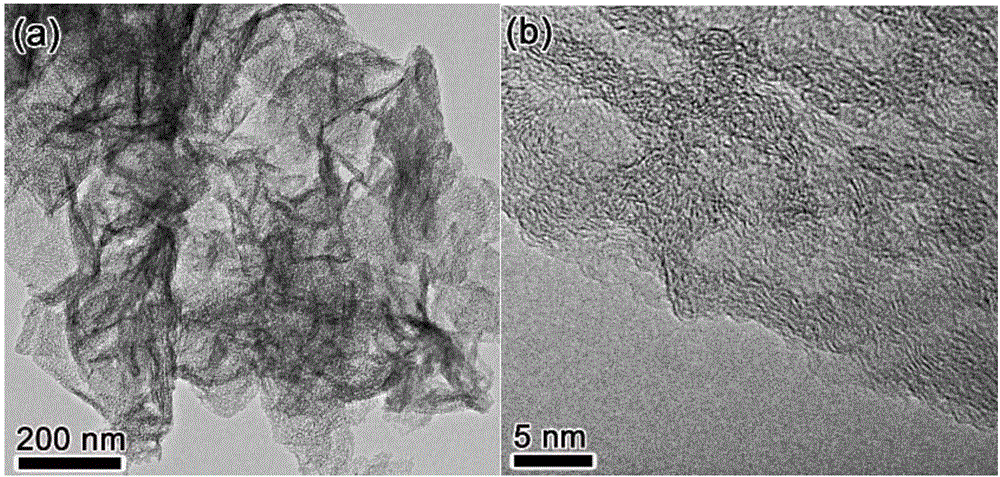

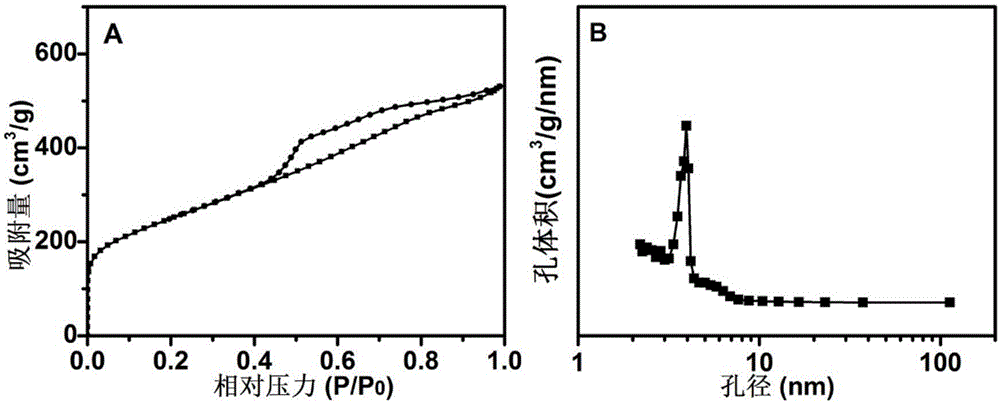

[0054] figure 1 Middle a and b are the low-magnification and high-magnification TEM images of the porous carbon material prepared at 500 °C, respectively. It can be seen f...

Embodiment 2

[0058] The present embodiment provides a kind of preparation method of porous graphene, it comprises the following steps:

[0059] 1) Weigh 10g of oil slurry, heat it to liquid state (60-90°C), add 20g of flake magnesium oxide, stir evenly, put it into a horizontal tube furnace, and then pass argon (Ar) into the furnace, while the horizontal furnace Raise the temperature to 900°C at a heating rate of 15°C / min, and keep it for 60min. After the furnace temperature is naturally cooled to room temperature, take out the gray product; It is obtained by mixing 1:3, wherein the mass percent concentration of concentrated hydrochloric acid is 37%), boiled and refluxed for pickling for 1 hour, and finally washed with deionized water until neutral and dried at 80°C to obtain a porous carbon material, No. for PC900.

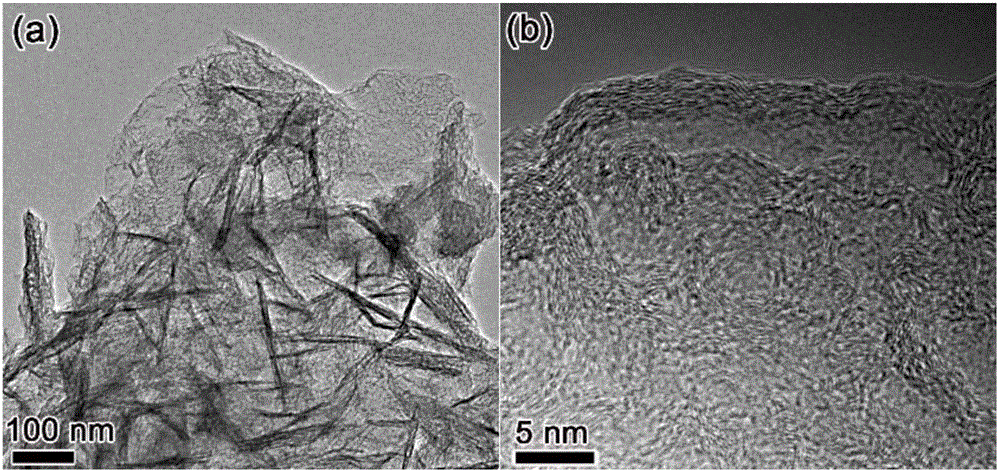

[0060] image 3 Middle a and b are the low-magnification and high-magnification TEM images of the porous carbon material prepared at 900 °C, respectively. It can be seen f...

Embodiment 3

[0068] The present embodiment provides a kind of preparation method of sulfur-doped porous graphene, it comprises the following steps:

[0069] Weigh 10g of oil slurry, heat it to liquid state (60-90°C), add 20g of magnesium sulfate whiskers, stir evenly, put it into a horizontal tube furnace, then pass Ar into the furnace, and at the same time, the horizontal furnace heats up at 15°C / min The rate was increased to 600°C and maintained for 60 minutes, and the gray product was taken out after the furnace was naturally cooled to room temperature. The product was placed in excess dilute hydrochloric acid, boiled and refluxed for pickling for 1 h, and finally washed with deionized water until neutral and dried at 80°C to obtain sulfur-doped porous carbon; the magnesium sulfate whiskers can be referred to MA , X; NING, G; QI, C; GAO, J, One-step synthesis of basic magnesium sulfate whiskers by atmospheric pressure reflux. Particuology 2016,24,191-196 in the preparation method;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com