Interdigital organic pollutant photodegradation device and preparation method thereof

A technology for organic pollutants and photodegradation, applied in water pollutants, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of low catalytic efficiency, complex process, and high production costs, and achieve high surface activity and production. Simple method and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of the present invention is as follows:

[0032] 1) see figure 1 , ultrasonically clean glass with a length and width of 34mm×34mm~35mm×35mm with acetone, absolute ethanol and deionized water, and dry at room temperature;

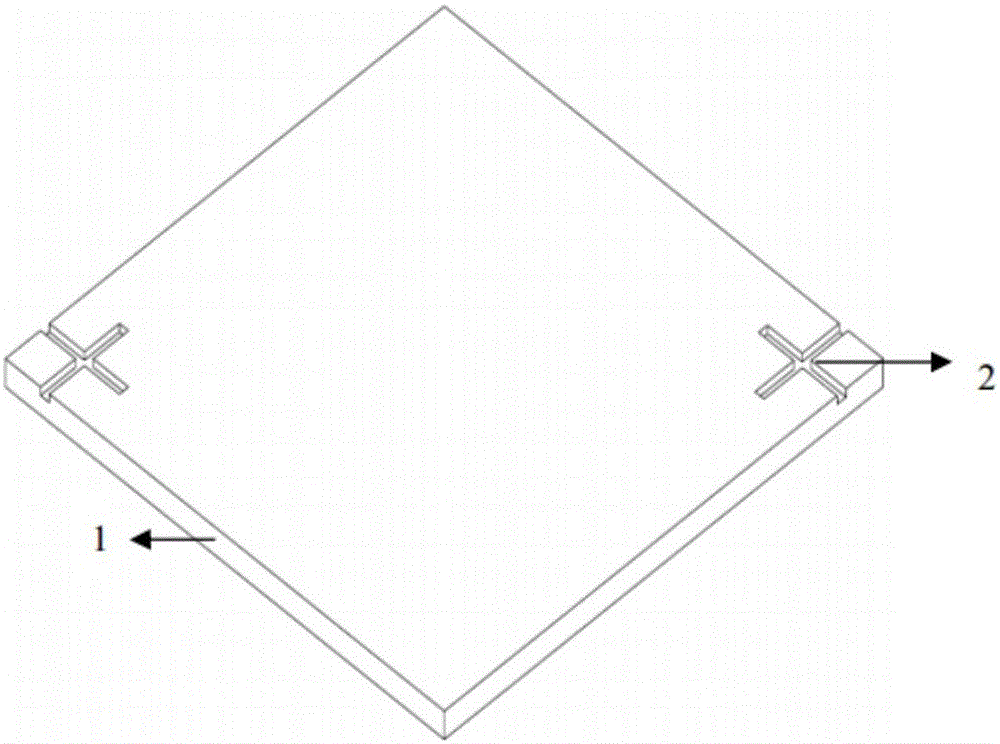

[0033] 2) see figure 2 , using a laser marking machine to make cross-shaped alignment marks on the upper right corner and lower left corner of one glass substrate respectively, and set cross-shaped alignment marks on the upper left corner and lower right corner of the second glass substrate, the length and width of the engraved lines are respectively 4-5mm, 1-2mm, and the horizontal and vertical distances of the two cross-shaped alignment marks are both 24-25mm, ultrasonic cleaning with absolute ethanol and deionized water in turn, and drying at room temperature;

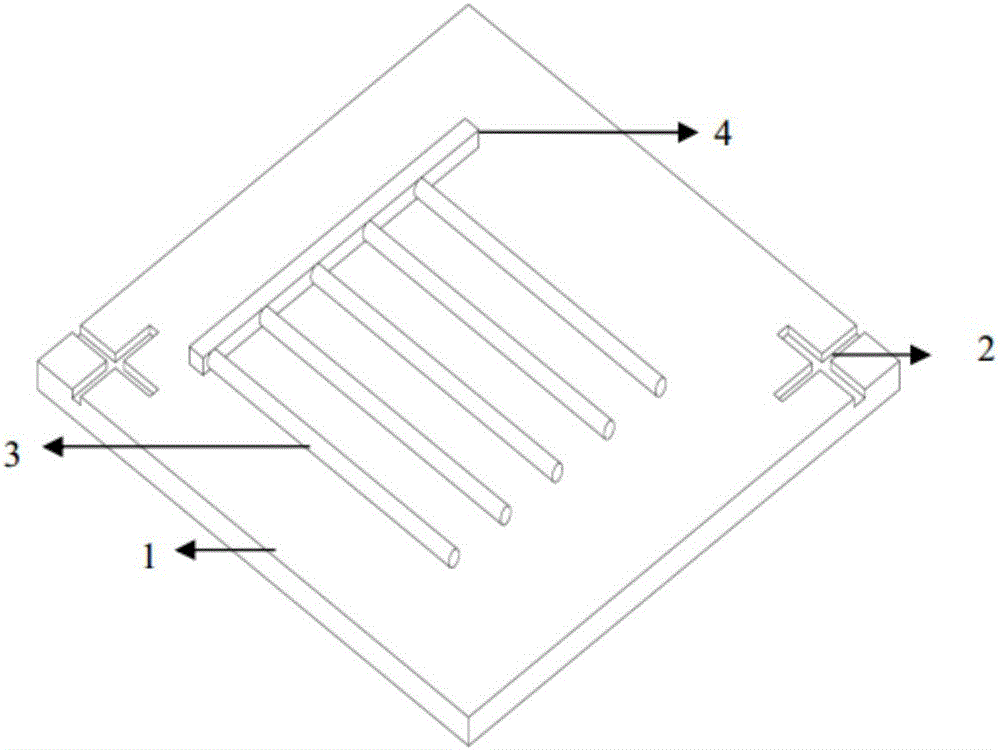

[0034] 3) Take several sections of optical fiber with a length of 2 to 3 cm, immerse them in acetone, pull out the fiber core from the cladding, ultrasonically cl...

specific Embodiment

[0043] The preparation method of the present invention comprises the following steps:

[0044] 1) Ultrasonic cleaning of glass with a length, width and thickness of 34mm×34mm×1mm with acetone, absolute ethanol and deionized water, and drying at room temperature, as figure 1 shown;

[0045] 2) Use a laser marking machine to make cross-shaped alignment marks on the upper right corner and lower left corner of the glass substrate respectively. 24mm, followed by ultrasonic cleaning with absolute ethanol and deionized water for 5 minutes, and dried at room temperature, such as figure 2 shown;

[0046] 3) Take several sections of optical fiber with a length of 2 cm, and immerse them in acetone for 10 minutes, pull out the fiber core from the cladding, ultrasonically clean them with absolute ethanol and deionized water for 5 minutes, and dry them at room temperature;

[0047] 4) Prepare PDMS glue with PDMSA:PDMSB at a mass ratio of 10:1;

[0048] 5) On the first glass substrate, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com