Method for treatment of mixed wastewater produced during production of rubber accelerator NS\CZ\DZ

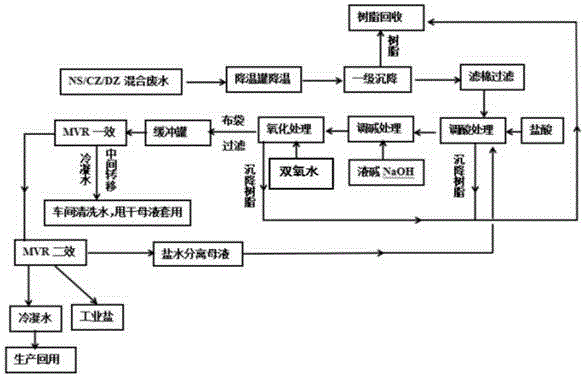

A technology of rubber accelerator and mixed sewage, which is applied in water/sewage treatment, heating water/sewage treatment, neutralized water/sewage treatment, etc. It can solve the problems of inoperability, inability to adopt, and single treatment process, so as to reduce COD , cost saving, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029]Mix the three kinds of water with 30m3 of waste water (COD value is 20000mg / L). At 50°C, use 31% hydrochloric acid to adjust the pH to 3. After settling for 15 minutes, release the resin, and filter the waste water with 32% liquid Adjust the pH to 8 with alkali (NaOH), add 0.5% hydrogen peroxide, release the settled resin after oxidation for 15 minutes, filter the supernatant with a cloth bag, enter the buffer tank at 30m3 / h and enter the first-effect evaporation to concentrate 20%, and the condensed water COD is 6000~6500mg / L, the concentrated liquid enters the second effect evaporation, desalination and separation, continuous operation, the COD of the second effect condensate is 300~400mg / L, and the odor of the waste water is reduced at the same time, the second effect condensate workshop is directly used as raw water Reuse, many batches have been produced and the quality is qualified to meet customer requirements. After cooling down, adjusting acidity, and oxidative s...

Embodiment 2

[0031] Mix the three kinds of water with 30m3 of waste water (COD value is 21000mg / L), at 70°C, adjust the pH to 4 with 31% hydrochloric acid, settle for 12 minutes, release the resin, and filter the waste water with 32% hydrochloric acid Adjust the pH to 8.5 with liquid caustic soda (NaOH), add 0.6% hydrogen peroxide to oxidize for 12 minutes, and release the settled resin. The supernatant is filtered with a cloth bag, and enters the buffer tank at 30m3 / h to enter the first-effect evaporation to concentrate 25%. The COD of the condensed water is 6500-7000mg / L, the mother liquor enters the second-effect evaporation for desalination and separation, continuous operation, the COD of the second-effect condensate is 650-700mg / L, and the odor of the waste water is reduced at the same time, the second-effect condensate workshop directly returns as raw water For use, many batches have been produced and the quality is qualified to meet customer requirements. After cooling down, adjusti...

Embodiment 3

[0033] Mix the three kinds of water with 30m3 of waste water (COD value is 23000mg / L), adjust the pH to 5 with 31% hydrochloric acid at 60°C, release the resin after settling for 10 minutes, filter the waste water with 32% liquid Alkali (NaOH) to adjust the pH to 9, add 0.8% hydrogen peroxide to oxidize for 10 minutes, release the settled resin, filter the supernatant with a cloth bag, enter the first effect evaporation at 30m3 / h and concentrate 30%, and the COD of the condensed water is 6000~6500mg / About L, the mother liquor enters the second-effect evaporation, desalination and separation, continuous operation, the COD of the second-effect condensate is 500-600mg / L, and the odor of the waste water is reduced at the same time, the second-effect condensate workshop is directly reused as raw water, and has been produced Multiple batches and quality are qualified to meet customer requirements. After cooling down, adjusting acidity, and oxidative sedimentation, the wet weight of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com