An early-strength phosphogypsum-based micro-expansion grouting material

A phosphogypsum and micro-expansion technology, applied in the field of building materials, can solve the problems of small application range and long setting time, and achieve the effects of good fluidity, short setting time and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

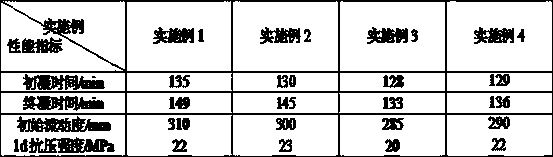

Embodiment 1

[0049] Example 1, an early-strength phosphogypsum-based micro-expansion grouting material, the mass ratio of each component is: 100 parts of phosphogypsum, 30 parts of slag powder, 15 parts of cement, 20 parts of fly ash, 10 parts of silica fume, quicklime 15 parts, 25 parts of quartz sand, 2.0 parts of nano-calcium silicate, 1.8 parts of water reducer, 0.05 parts of triethanolamine, and 0.5 parts of sodium chloride. The preparation of the grouting material takes the following steps: 1) Weigh the required phosphogypsum, slag powder, cement, fly ash, silica fume, quicklime, quartz sand, and nano-calcium carbonate according to the aforementioned weight ratio, and fully stir them evenly in a mixer , form the product, and carry out bagging; 2) Transport the aforementioned product to the construction site, and according to the actual required performance requirements, measure 20% of the powder weight mixing water, and mix the water reducing agent, Add triethanolamine and sodium chl...

Embodiment 2

[0050]Example 2, an early-strength phosphogypsum-based micro-expansion grouting material, the mass ratio of each component is: 100 parts of phosphogypsum, 33 parts of slag powder, 18 parts of cement, 22 parts of fly ash, 12 parts of silica fume, quicklime 18 parts, 20 parts of quartz sand, 4.0 parts of nano-calcium silicate, 2 parts of water reducer, 0.1 part of triethanolamine, and 0.1 part of sodium chloride. The preparation of the grouting material takes the following steps: 1) Weigh the required phosphogypsum, slag powder, cement, fly ash, silica fume, quicklime, quartz sand, and nano-calcium carbonate according to the aforementioned weight ratio, and fully stir them evenly in a mixer , form the product, and carry out bagging; 2) transport the aforementioned product to the construction site, and according to the actual required performance requirements, measure the mixing water of 22% of the weight of the powder, and mix the water reducing agent, Add triethanolamine and so...

Embodiment 3

[0051] Example 3, an early-strength phosphogypsum-based micro-expansion grouting material, the mass ratio of each component is: 100 parts of phosphogypsum, 37 parts of slag powder, 22 parts of cement, 27 parts of fly ash, 20 parts of silica fume, quicklime 23 parts, 35 parts of quartz sand, 1.0 part of nano-calcium silicate, 2.2 parts of water reducer, 0.12 part of triethanolamine, and 0.2 part of sodium chloride. The preparation of the grouting material takes the following steps: 1) Weigh the required phosphogypsum, slag powder, cement, fly ash, silica fume, quicklime, quartz sand, and nano-calcium carbonate according to the aforementioned weight ratio, and fully stir them evenly in a mixer , form the product, and carry out bagging; 2) Transport the aforementioned product to the construction site, and according to the actual required performance requirements, measure 25% of the powder weight mixing water, and mix the water reducing agent, Add triethanolamine and sodium chlori...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| power level | aaaaa | aaaaa |

| water reduction rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com