Synthesis method for aryl azide compound

A synthetic method, the technology of aryl azide, which is applied in the field of synthesis of azide compounds, can solve the problems of harsh conditions, small scope of application, low yield, etc., and achieve the effects of mild reaction conditions, wide selection range, and simple raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

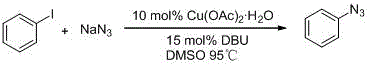

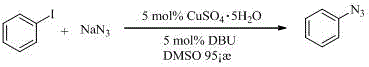

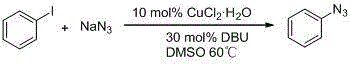

Method used

Image

Examples

Embodiment 1

[0009] Using different copper salts as catalysts, 1.0mmol iodobenzene, 1.2mmol sodium azide, 0.2mmol DBU and 0.1mmol catalyst were sequentially added to a reaction flask containing 3.0mL dimethyl sulfoxide, and the reaction mixture was heated at 95 Stir the reaction at ℃, track the reaction until the reaction is complete by TLC, add a few drops of ammonia water to the reaction mixture, then extract with ethyl acetate (10mL×3), wash with saturated brine once, dry, filter with suction, spin off the solvent, and The target product was obtained through chromatographic purification, and the influence of different catalysts on the reaction yield is shown in Table 1.

[0010] Table 1 Effect of different catalysts on reaction yield

[0011] Group catalyst Reaction time (h) Yield (%) 1 Cu(OAc) 2 ·H 2 o

Embodiment 2

[0013] Add 1.0mmol of iodobenzene, 1.2mmol of sodium azide, 0.2mmol of DBU and 0.1mmol of copper acetate to a reaction flask containing 3.0mL of solvent in sequence, and stir the reaction mixture at 95°C for a reaction, followed by TLC until the reaction is complete. Add a few drops of ammonia water to the reaction mixture, then extract with ethyl acetate (10mL×3), wash once with saturated brine, dry, filter with suction, spin off the solvent, and purify by column chromatography to obtain the target product. The impact of the yield is shown in Table 2.

[0014] Table 2 Effect of different solvents on the reaction yield

[0015] Group solvent Reaction time (h) Yield (%) 1 DMSO 1.5 93 2 DMF 5.0 80 3 MeOH 8.0 45 4 EtOH 8.0 40 5 h 2 o

Embodiment 3

[0017]

[0018] Add 1.0mmol of iodobenzene, 1.2mmol of sodium azide, 0.15mmol of DBU and 0.1mmol of copper acetate to a reaction flask containing 3mL of dimethyl sulfoxide, and stir the reaction mixture at 95°C for 1.5h, followed by TLC. After the reaction is complete, add a few drops of ammonia water to the reaction mixture, then extract with ethyl acetate (10mL×3), wash once with saturated brine, dry, filter with suction, spin off the solvent, and purify by column chromatography to obtain the target product , yield 92%.

[0019] Data characterization of phenyl azide: pale yellow liquid; 1 H NMR (400 MHz, CDCl 3 ) δ: 7.38-7.34 (m,2H), 7.15 (t, J = 8.0 Hz, 1H), 7.04 (d, J = 8.0 Hz, 2H). 13 C NMR (100 MHz, CDCl 3 ) δ: 140.0, 129.8, 124.9, 119.0.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com