A film-forming agent for seed coating, its preparation method and application

A film-forming agent and seed technology, applied in the direction of seed coating/seed dressing, etc., can solve problems such as affecting the stability and biological activity of the seed coating agent, difficult to maintain active ingredients, and unstable efficacy of the drug, and achieve coating The effect of high uniformity, excellent safety, and low shedding rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

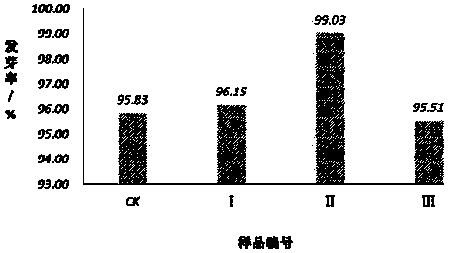

Examples

Embodiment 1-3

[0027] 1. Preparation of film-forming agent for rice seed coating

[0028] Weigh 1.5g of the initiator potassium persulfate into a 100mL Erlenmeyer flask, add 30mL of ultrapure water to shake and dissolve, and place in the refrigerator for later use. Weigh 2g of sodium bicarbonate (as an acid-binding agent), 1.2g of OP-10, stir in an appropriate amount of 100g of water until there is no obvious turbidity, add 0.22mol of styrene, 0.27mol of butyl acrylate, and 0.1mol of acrylamide, and emulsify with a high-speed disperser Cut for 15min. Transfer 40 g of the pre-emulsion to a four-necked flask, stir in a collector-type constant temperature heating magnetic stirrer, and raise the temperature to 78°C, add 5 mL of the initiator dropwise, and drop it in about 30 minutes. When the reflux of the reaction emulsion intensifies and blue fluorescence is visible, it proves that the emulsion polymerization reaction has started, and then the remaining monomer emulsion and 17mL initiator are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com